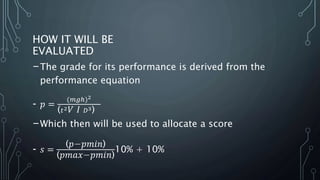

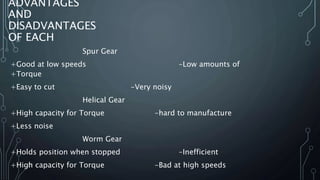

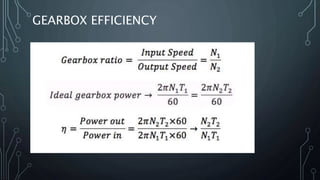

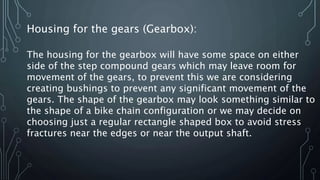

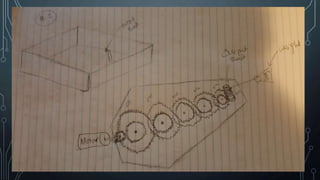

This document discusses the design of a gearbox to lift an 8kg weight 0.5m high using only acrylic sheets and glue. It must not fail or crack under the load. The team will evaluate the design using a performance equation factoring in variables like time, voltage, current and gear diameter. They determined helical gears would be most suitable but are difficult to manufacture. The document analyzes different gear types, gear ratios, energy transfer, losses and optimizing the gearbox ratio to safely exceed the required torque with a 20% factor of safety. It proposes a compound gearbox configuration with stepped reductions and bushings to prevent gear movement in the housing.