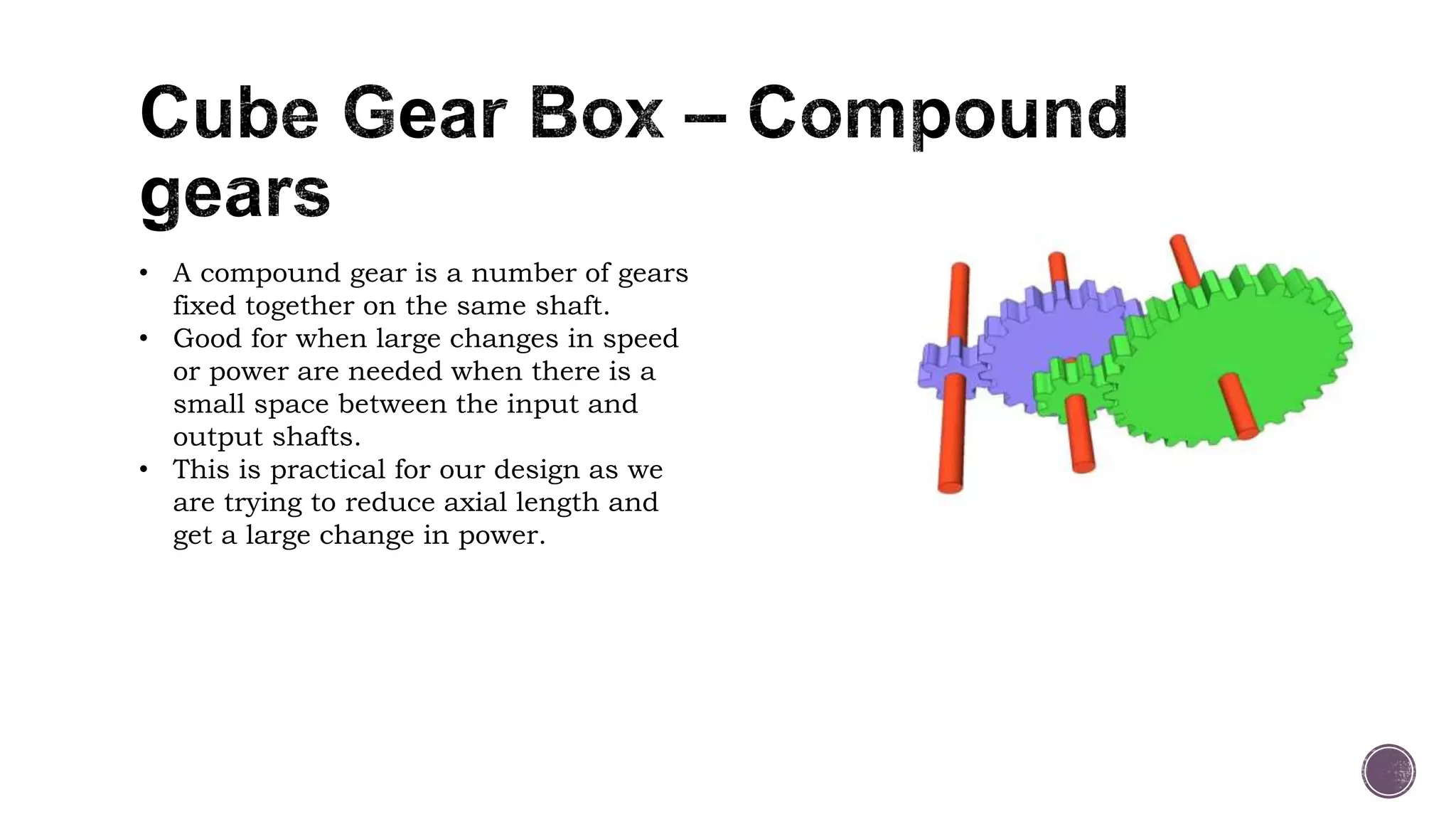

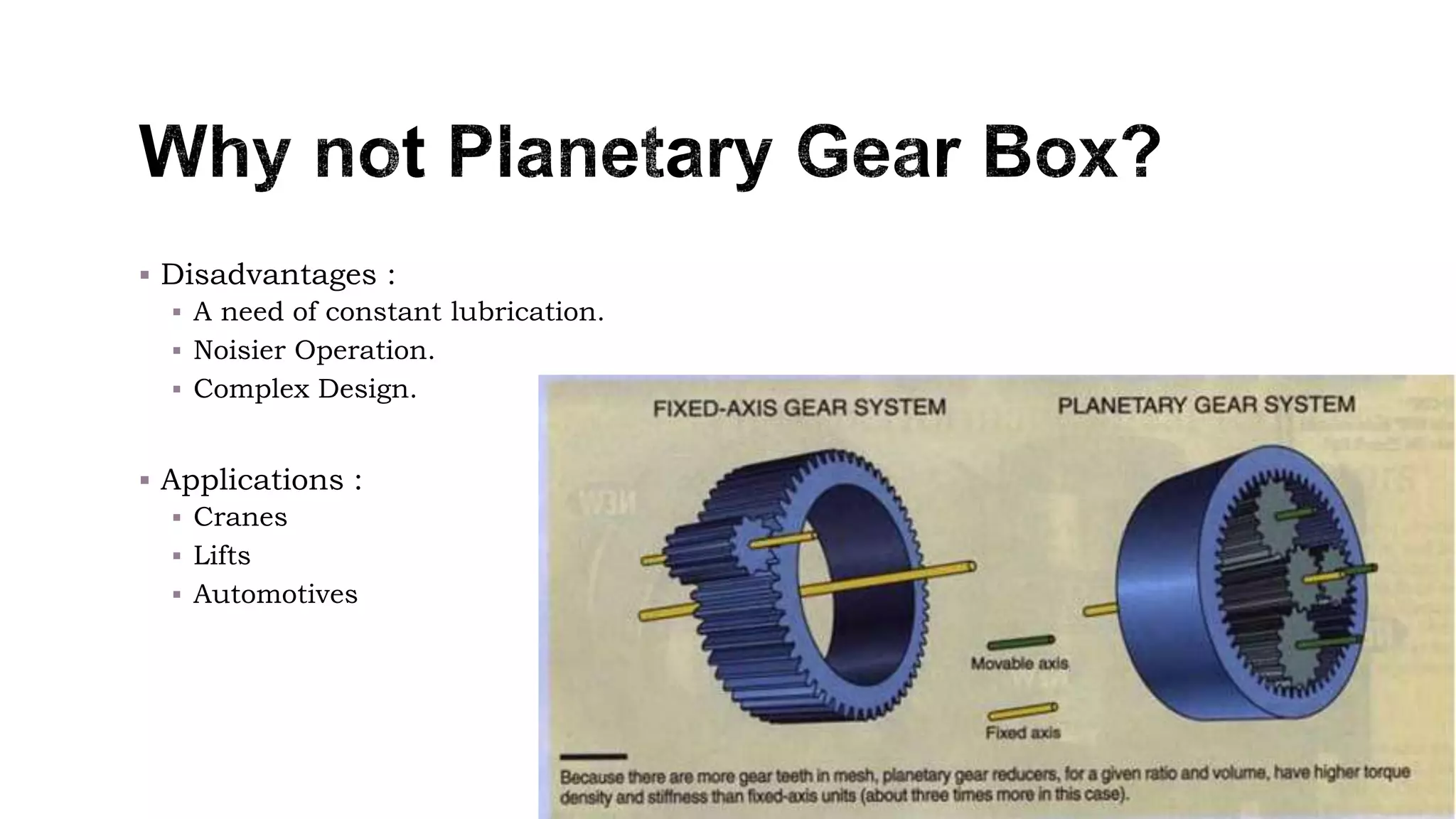

The document outlines the gear box project plan. The team aims to design a planetary gear box with compound gears to maximize power ratio while minimizing axial length. This will help achieve the goals of reducing lift time and maximum axial length to score close to 20% in the performance equation. The team will use floating compound gears on two fixed shafts, held in place by washers, to achieve a high gear ratio. Factors like gear ratios, torque, power, and efficiency are considered.