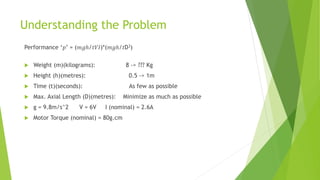

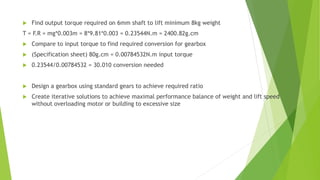

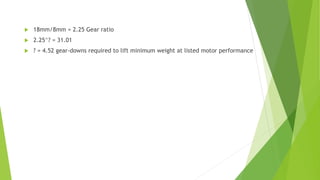

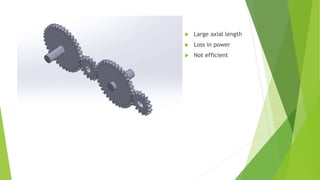

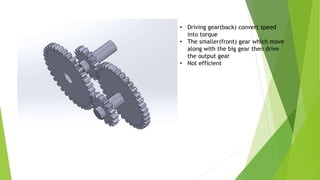

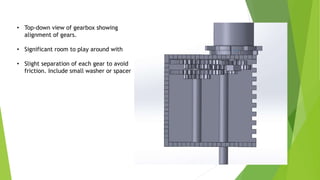

The document discusses the design of a gearbox to lift a minimum weight of 8kg 1m in height within the fewest seconds possible using a motor with specified torque. It determines a gear ratio of at least 30.1x is needed. Initial gearbox designs are considered but found inefficient due to long length, power loss, or complexity. A final proposed design uses a compact overlapping planetary gear system in a cubic shape for maximum volume efficiency to meet the project goals.