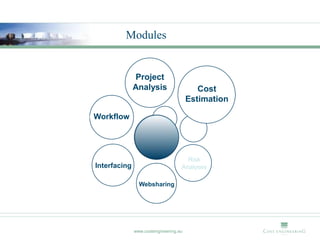

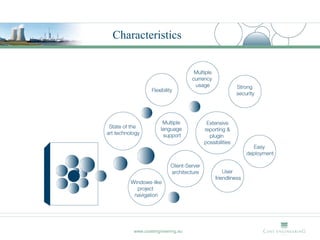

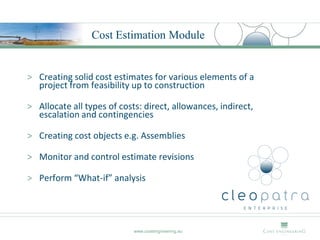

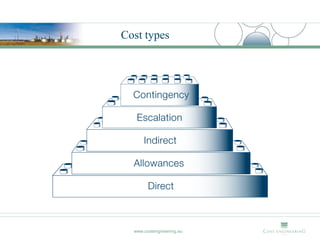

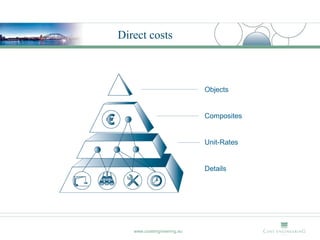

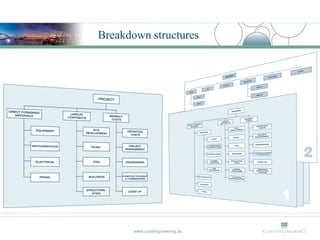

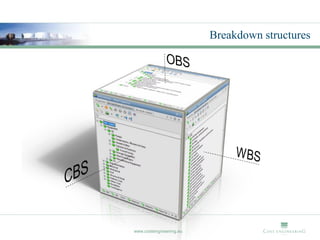

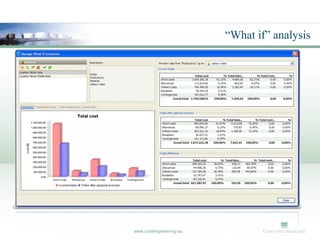

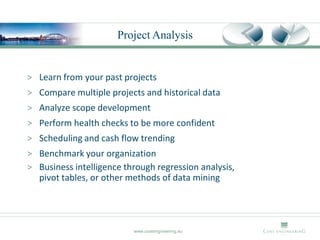

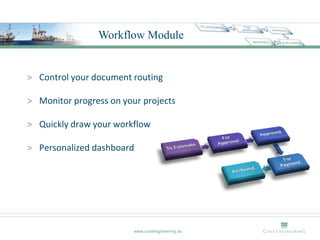

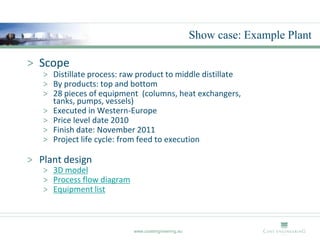

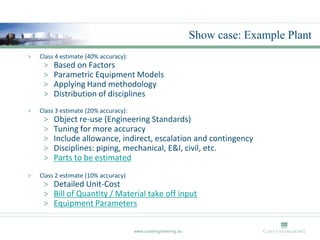

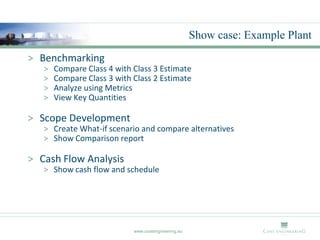

The document provides an overview of cost engineering, highlighting services such as cost data development, professional training, and project lifecycle support using Cleopatra Enterprise software. It emphasizes the importance of accurate cost estimation and project analysis, offering various estimating classes from Class 4 to Class 2, along with workflows and modules for managing documentation and project progress. Additionally, it presents examples of past projects and showcases how to benchmark and analyze cost estimates for improved decision-making.