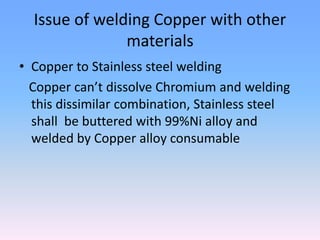

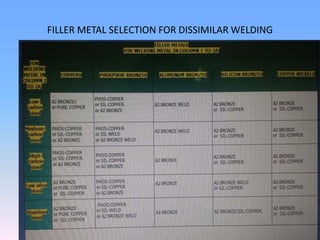

Copper and copper alloys are widely used for their electrical and thermal conductivity. Major copper alloys include aluminum bronze, nickel copper, tin bronze, and zinc bronze. Aluminum bronze contains 3-15% aluminum and has increased strength but decreased ductility. Nickel copper contains 3-30% nickel and has increased strength and toughness. Tin bronze contains 2-10% tin and has increased fatigue resistance and hardness. Zinc bronze contains 20-36% zinc and has increased strength and thermal expansion. When welding copper alloys, factors like dual phase microstructures, oxide inclusions, and element evaporation must be considered and addressed through techniques like preheating and post-heating. Dissimilar welds