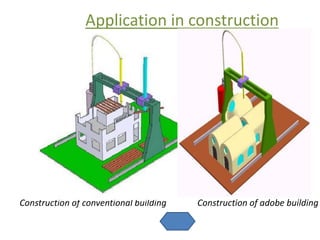

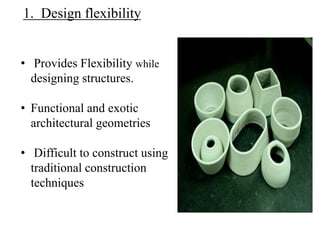

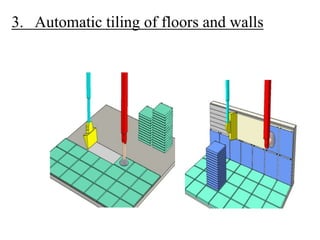

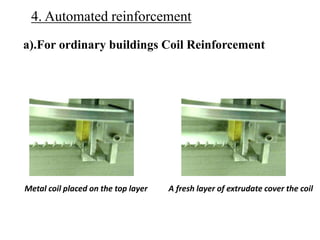

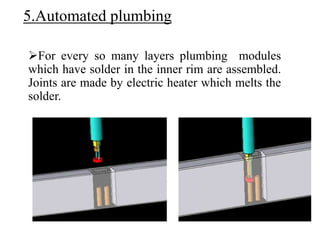

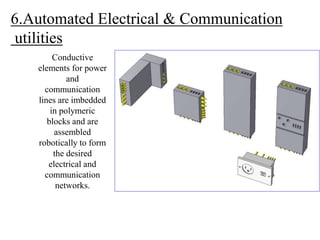

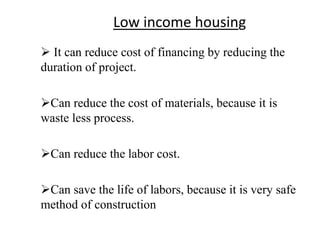

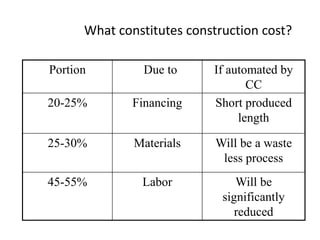

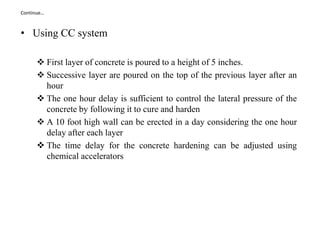

Contour crafting is an automated construction method that uses computer-controlled equipment to construct buildings by depositing materials in layers. It allows entire structures to be built rapidly through an additive fabrication process. Contour crafting embeds elements like plumbing, electrical wiring, and reinforcement during construction. It provides benefits like design flexibility, faster construction, lower costs, and improved safety compared to traditional methods. Potential applications include emergency housing, low-income housing, and commercial construction.