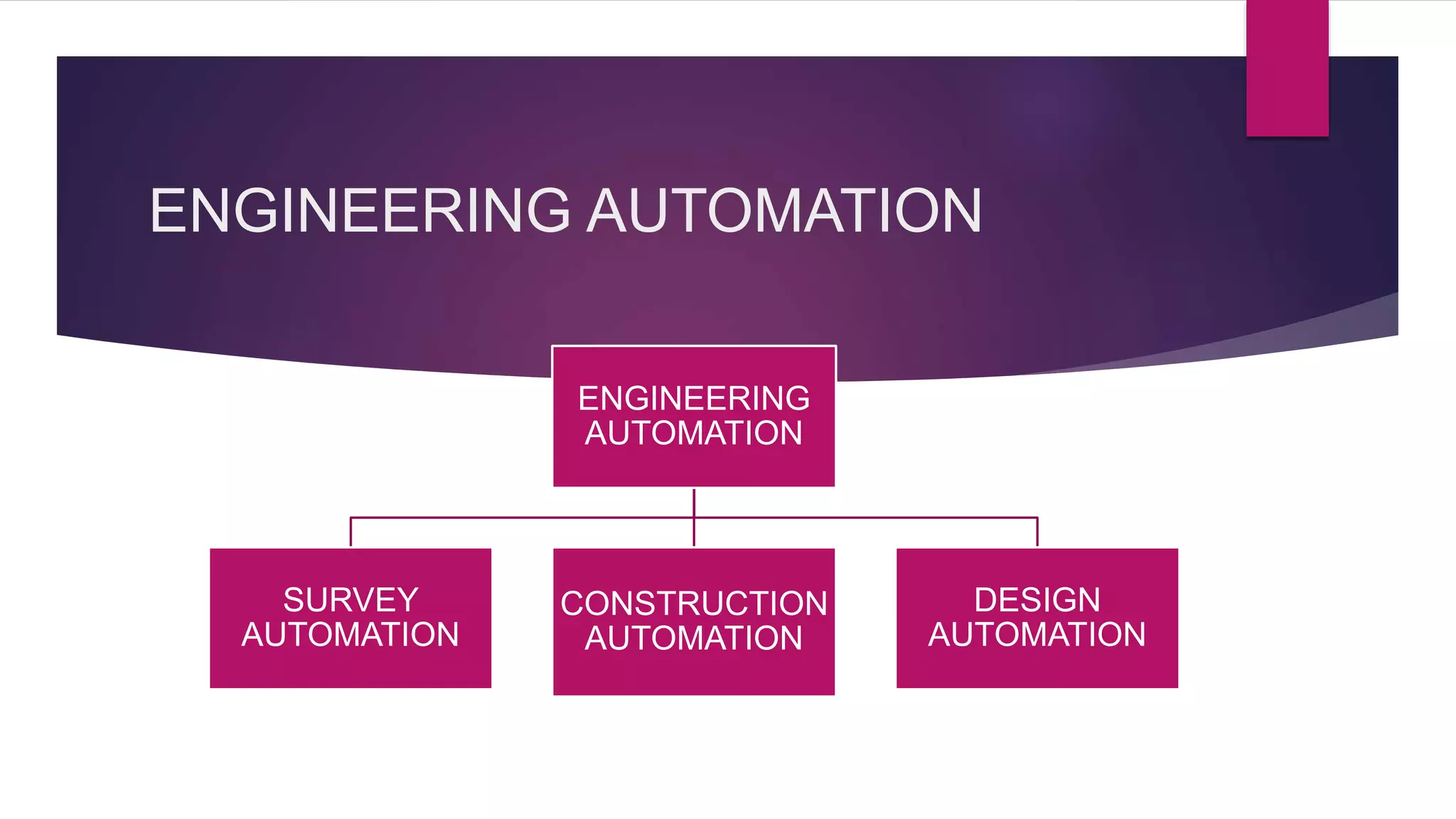

The document discusses automation in the construction industry. It defines automation in construction as the use of automatic equipment or processes to aid construction work. Key benefits of automation include improved efficiency, productivity, safety and quality control. Examples of automation discussed include pre-cast concrete production, tower cranes for material movement, tunnel boring machines, and use of total stations in surveying. The conclusion states that increased automation can help address issues like labor shortages and improve quality and productivity in the growing construction sector in countries like India.