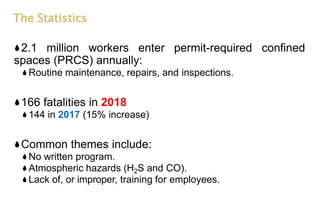

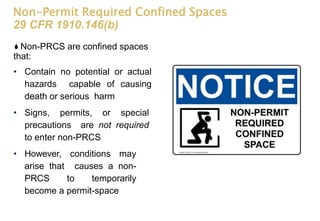

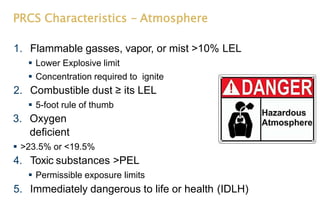

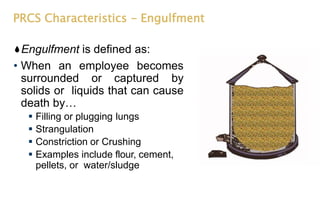

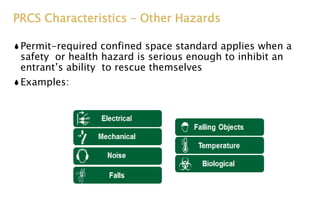

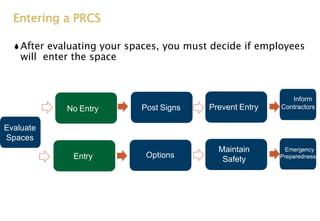

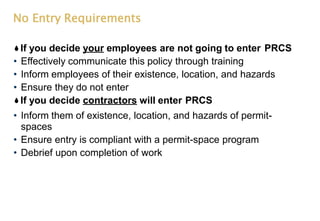

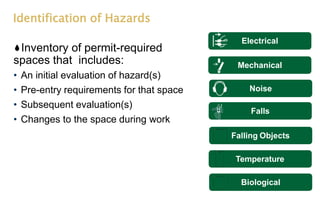

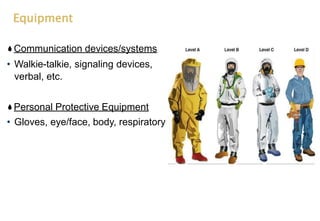

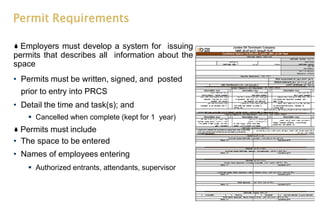

This document summarizes a presentation on confined space safety. It defines what a confined space is according to OSHA standards, and categorizes spaces as permit-required or non-permit required. It outlines the hazards associated with permit-required confined spaces including atmospheric, engulfment, and configuration hazards. The presentation reviews entry options and requirements for a permit-required confined space program including identifying hazards, procedures, equipment, responsibilities, permits, and training. It emphasizes the importance of evaluating all spaces, having appropriate entry procedures and equipment, clearly defined roles and responsibilities, and a permit system for safely entering permit-required confined spaces.