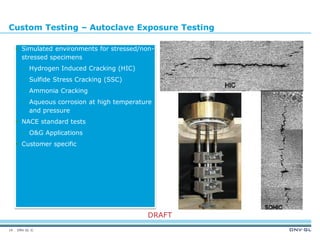

This document describes materials testing and corrosion services provided by DNV GL. It discusses DNV GL's 18 laboratories across three continents that offer a broad range of testing services. These include consulting, research and testing, customized tests, failure analysis, and training. The document focuses on DNV GL's capabilities for corrosion studies including flow induced corrosion testing using large scale flow loops, rotating cylinder experiments, and autoclave testing. It also discusses computational modeling and analytical facilities for corrosion identification.