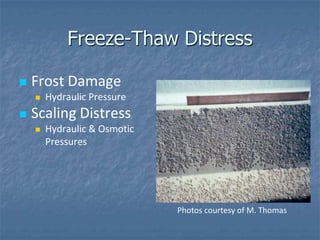

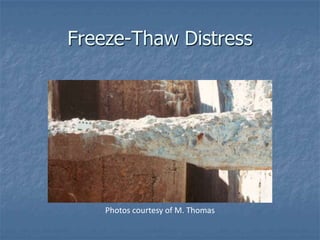

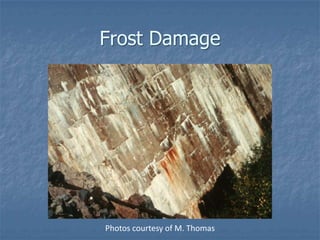

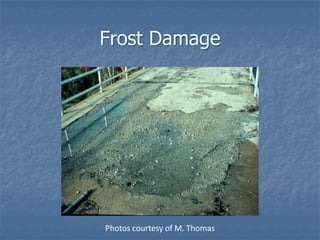

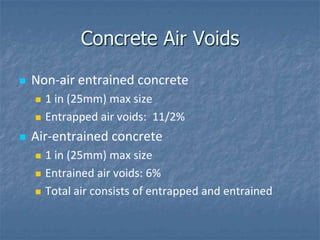

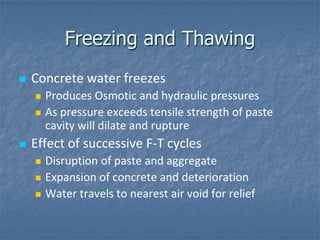

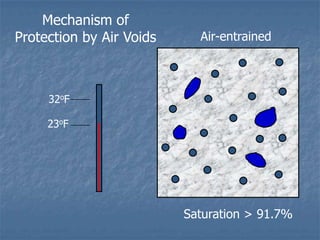

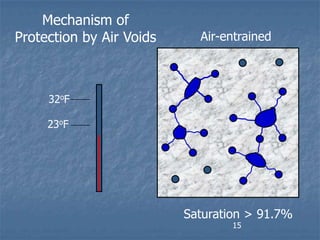

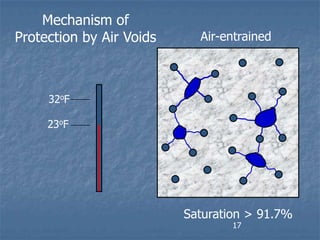

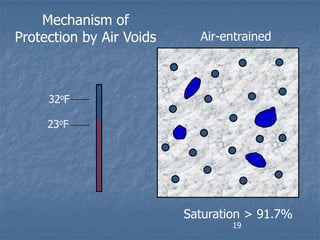

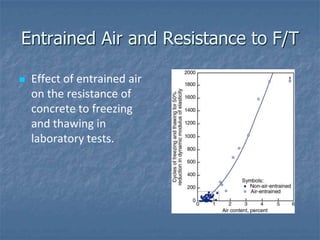

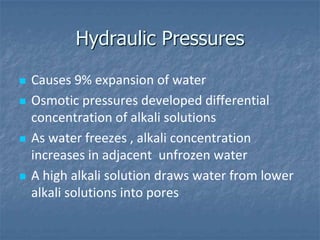

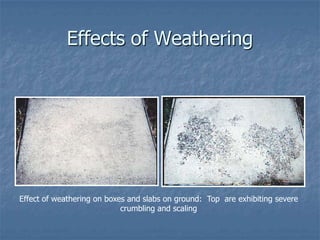

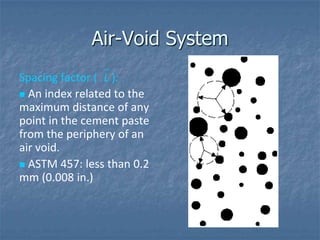

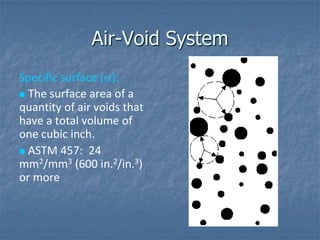

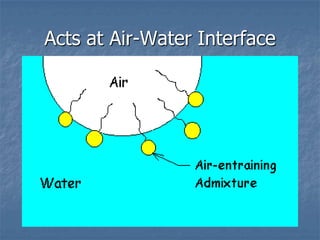

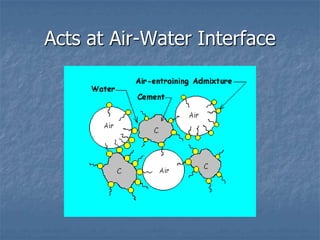

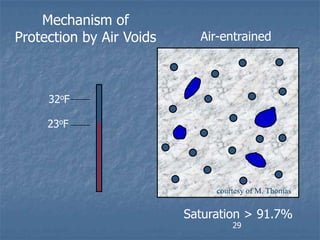

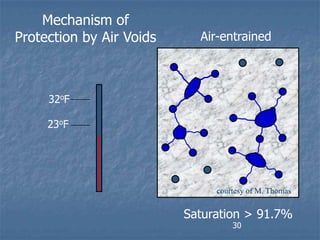

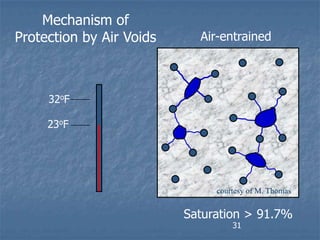

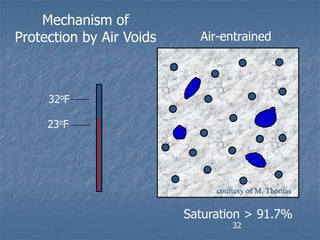

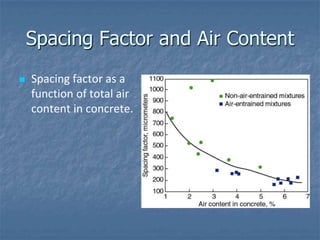

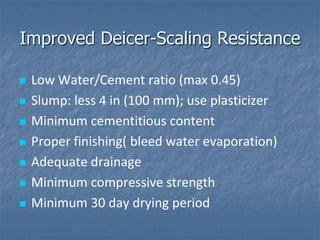

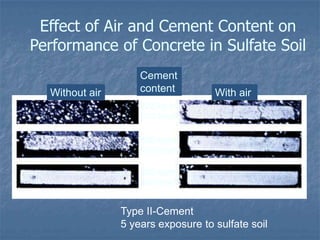

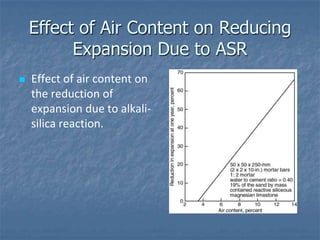

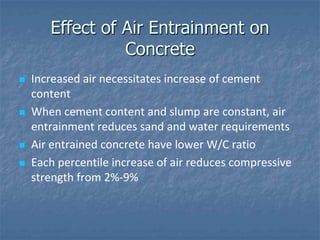

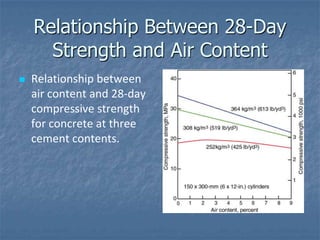

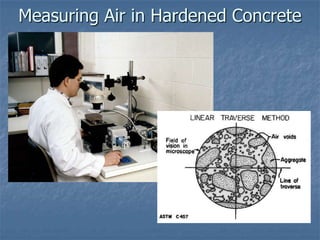

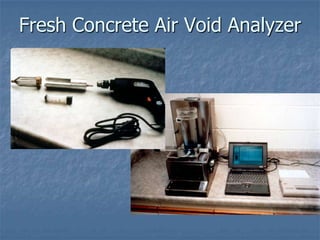

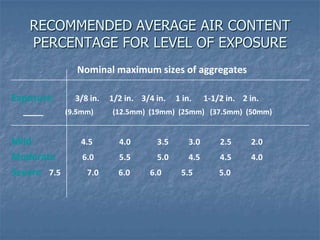

The document discusses air entraining admixtures, which generate tiny stable bubbles in concrete to protect against freezing and thawing cycles by providing spaces for expanding water to enter and exit without damaging the concrete; it describes how air entrainment improves durability in freeze-thaw and deicer exposed environments and explains the mechanism by which air voids in concrete provide this protection against frost damage and scaling.