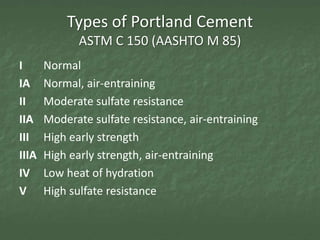

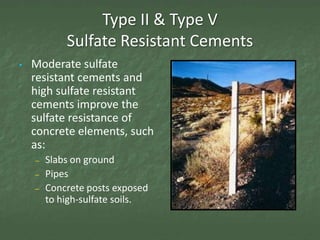

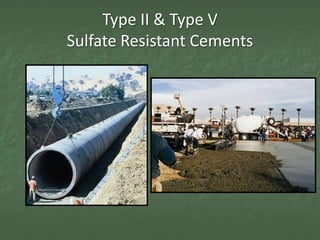

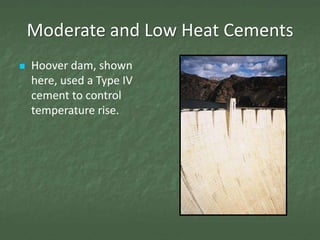

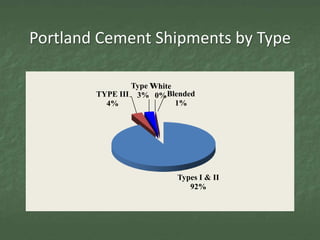

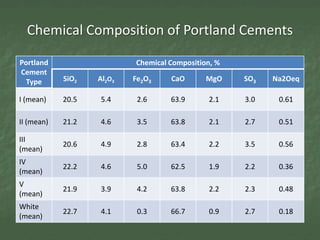

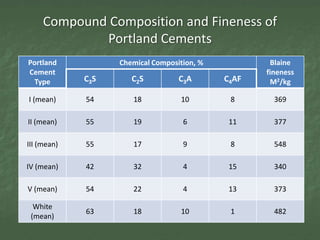

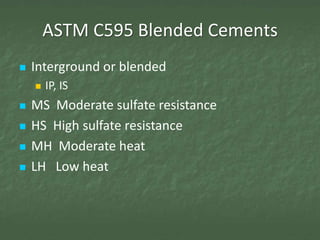

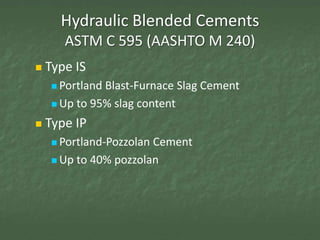

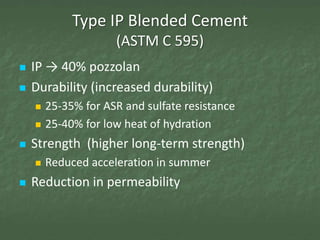

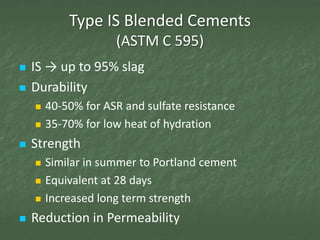

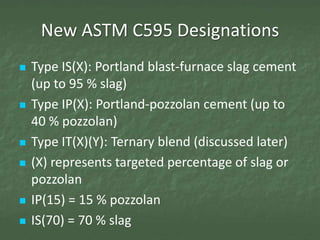

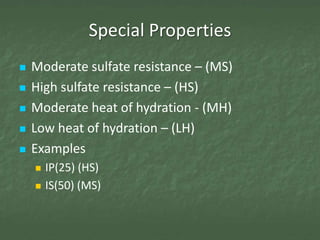

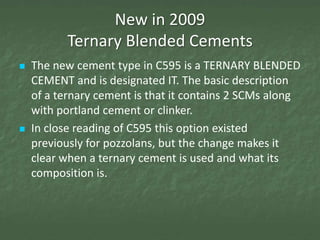

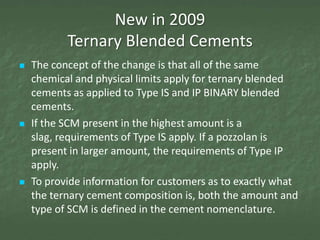

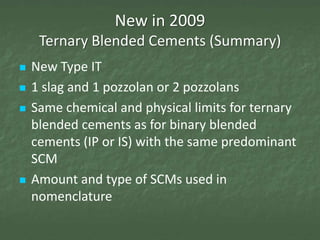

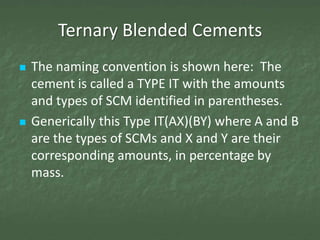

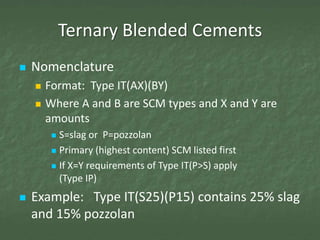

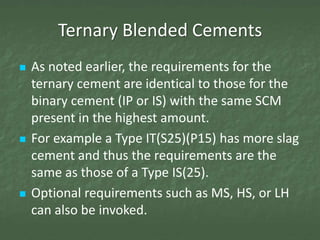

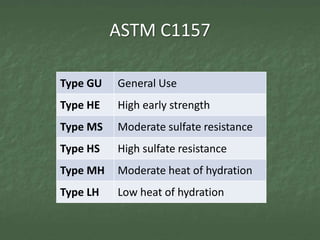

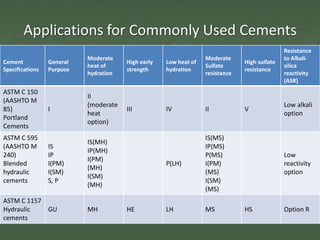

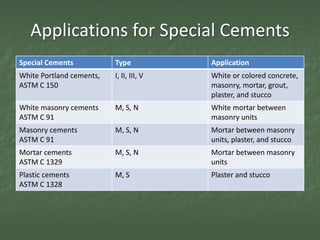

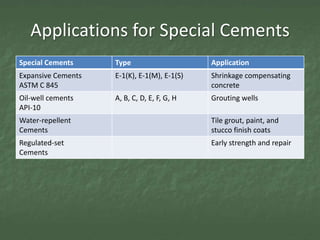

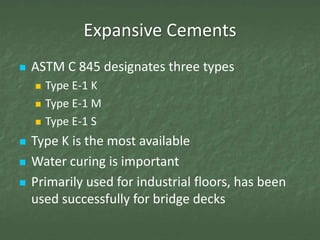

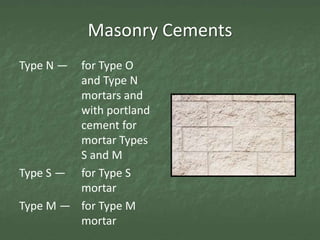

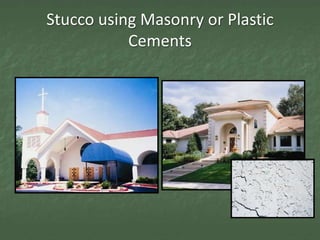

The document discusses various types of hydraulic cements, including Portland cements that meet ASTM C150 specifications for types I through V, as well as blended cements that combine Portland cement with supplementary cementitious materials like fly ash or slag to provide benefits like improved durability or reduced heat generation. Specialty cements are also covered, such as white cement, masonry cement, and expansive cement used for applications requiring shrinkage compensation.