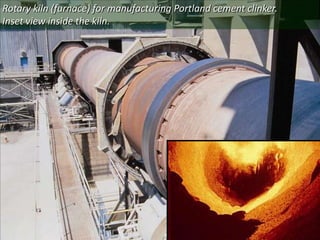

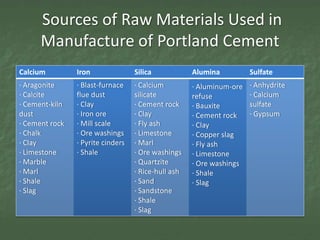

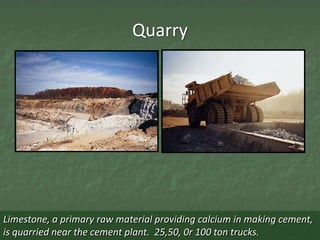

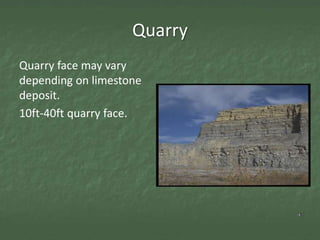

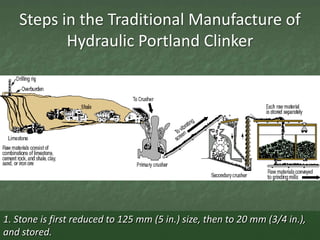

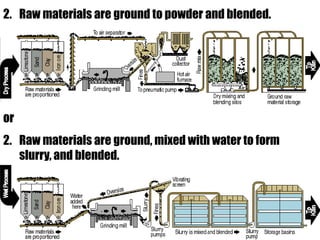

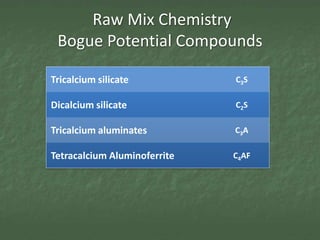

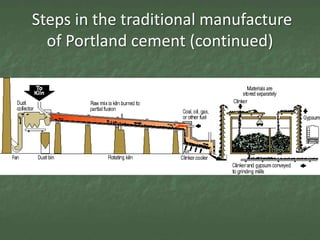

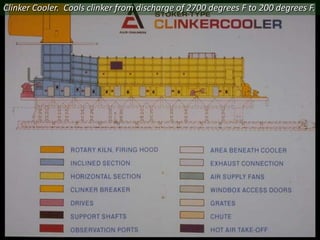

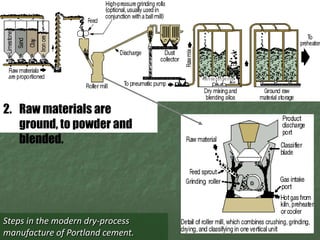

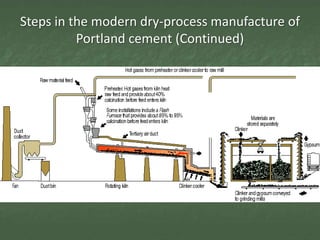

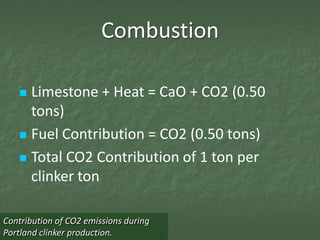

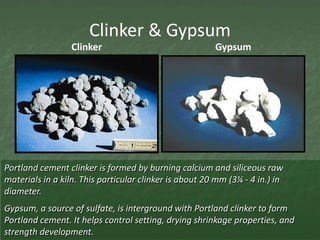

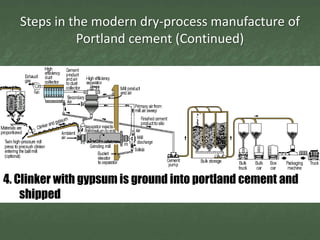

The document discusses the raw materials and manufacturing process for Portland cement. Key raw materials include limestone, silica, alumina, and iron which are ground and blended. The blended raw mix is then burned at high temperatures in a kiln to form cement clinker in a chemical reaction. The clinker is then ground with gypsum to produce Portland cement, which is stored and delivered. Modern dry processing uses a preheater and precalciner to burn the raw mix more efficiently in a shorter kiln.