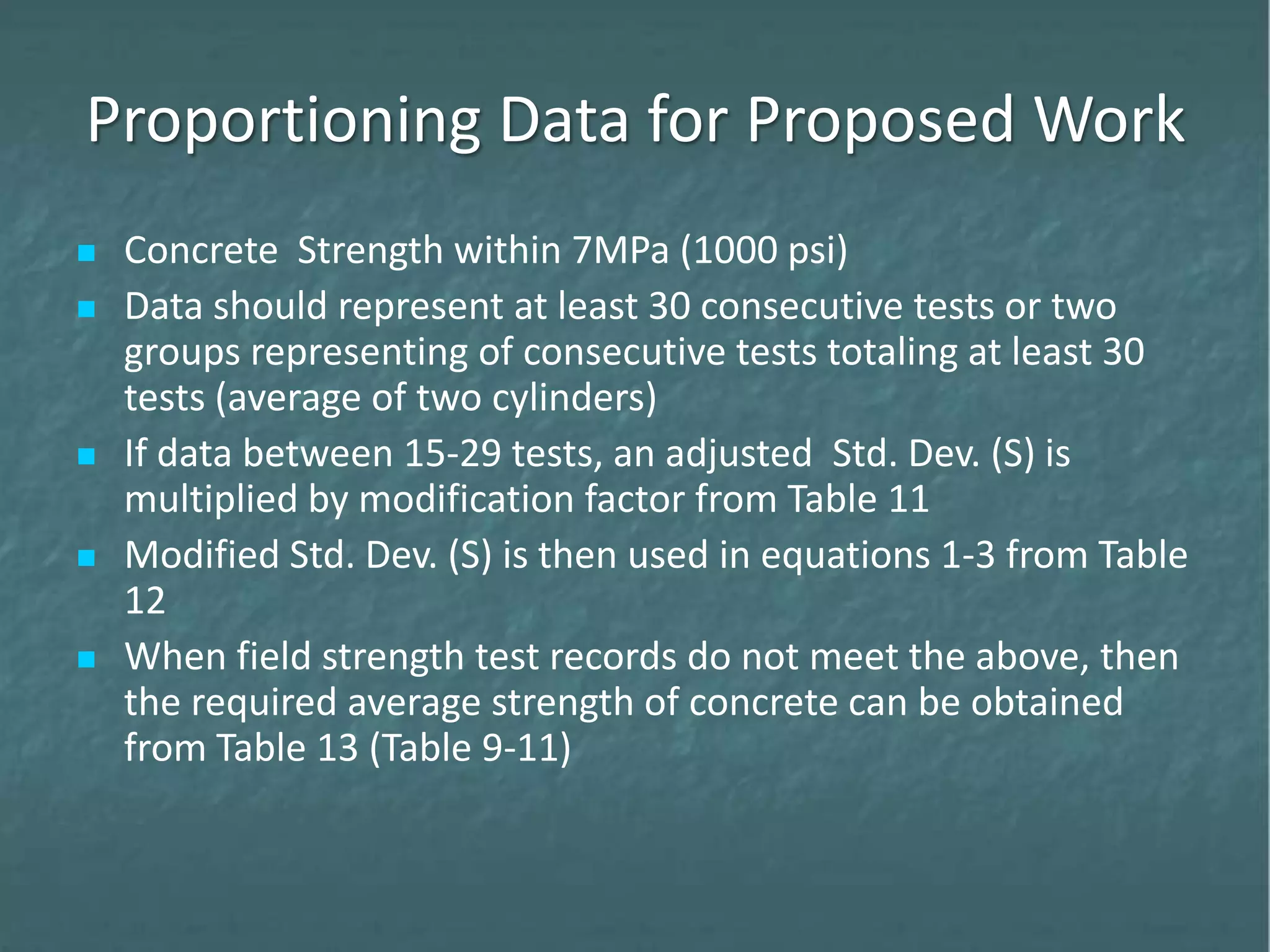

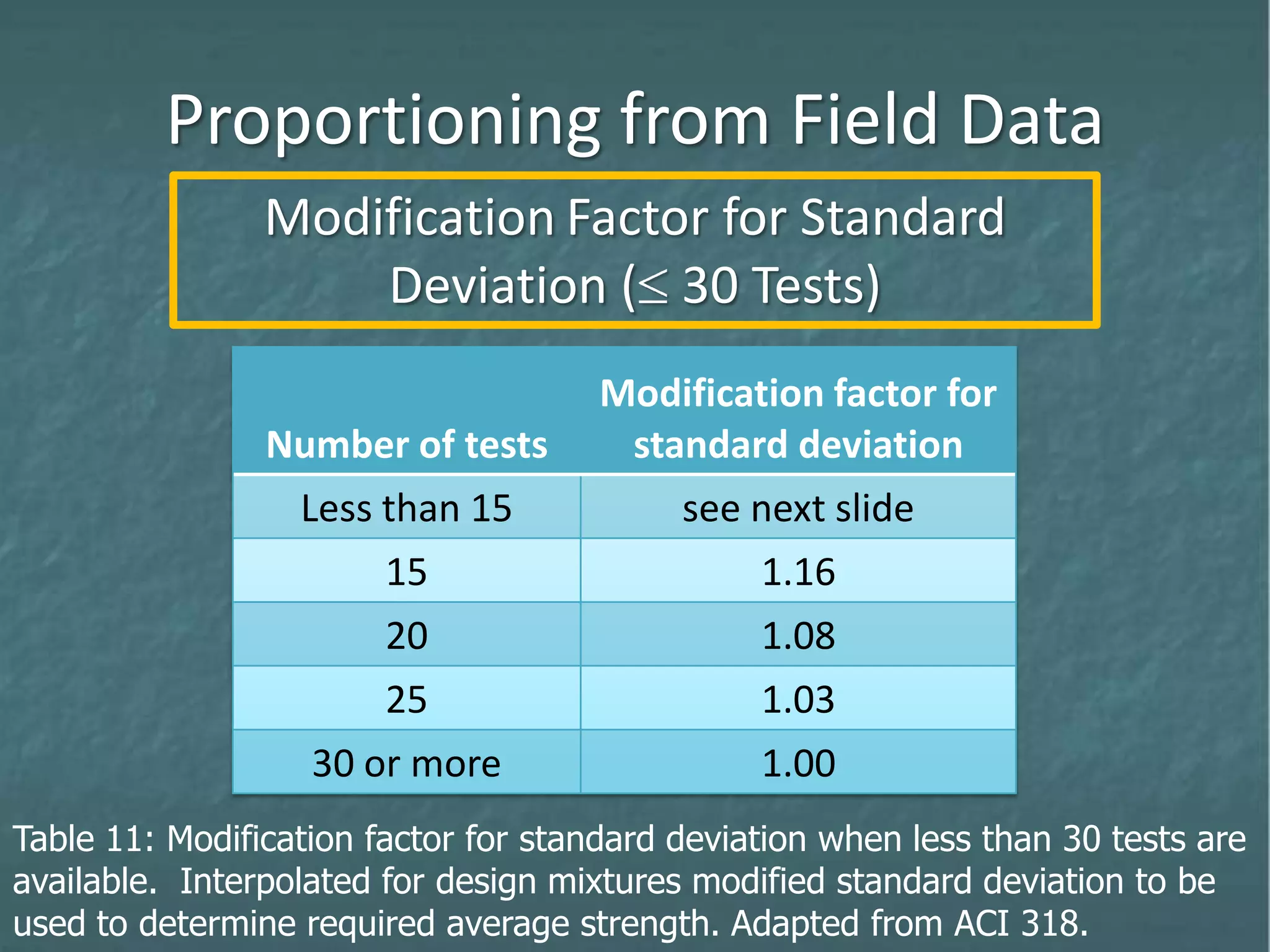

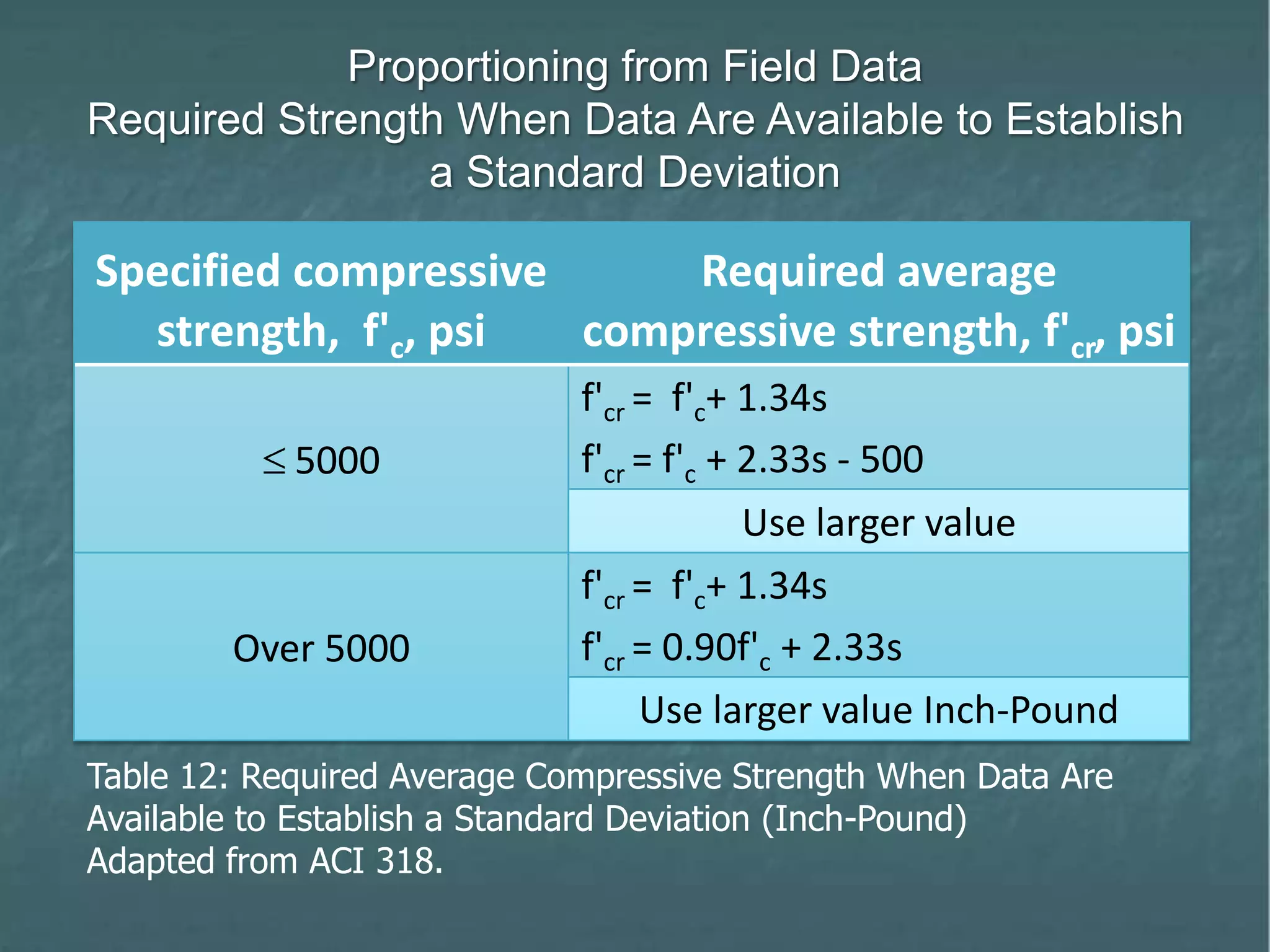

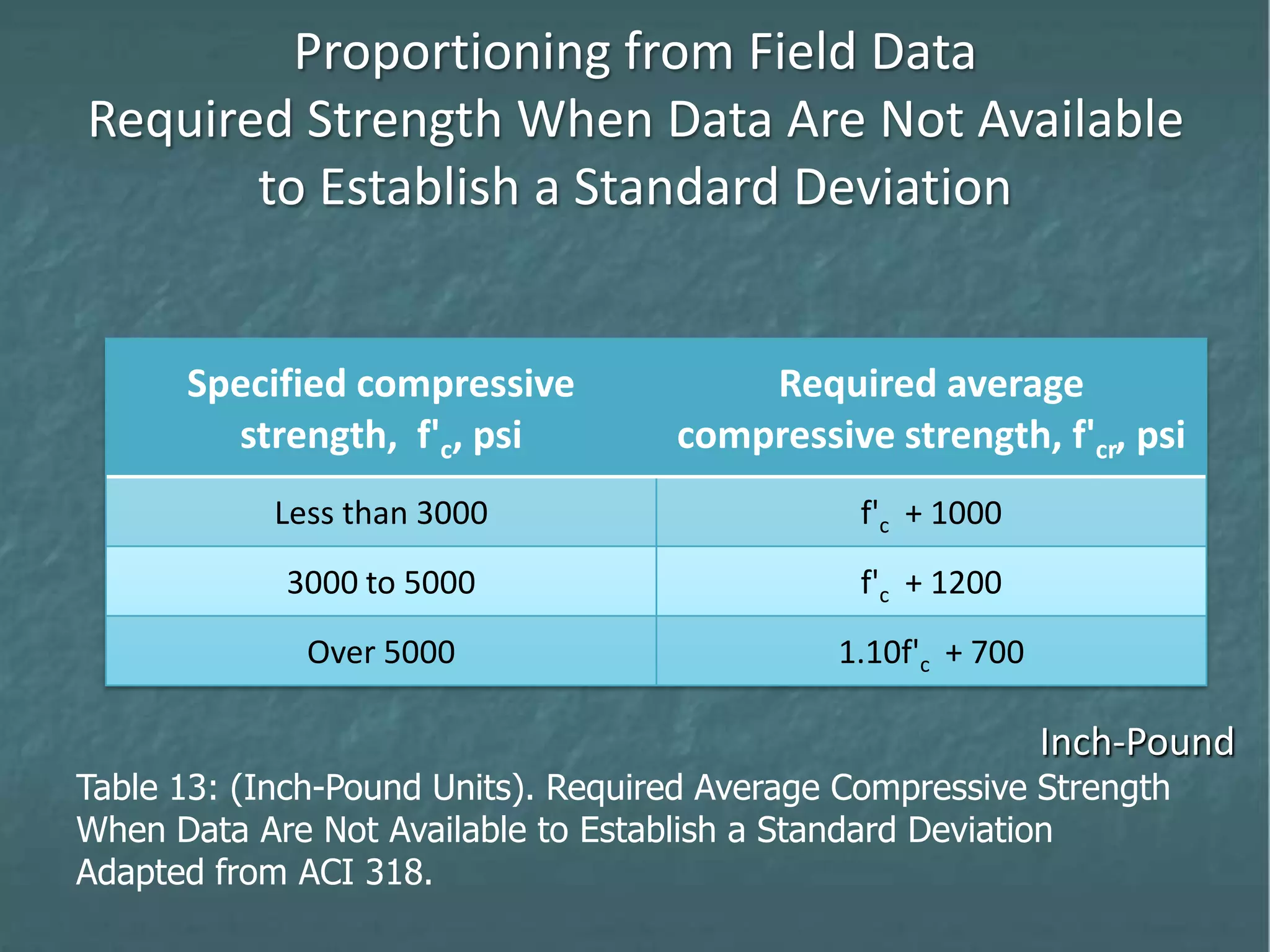

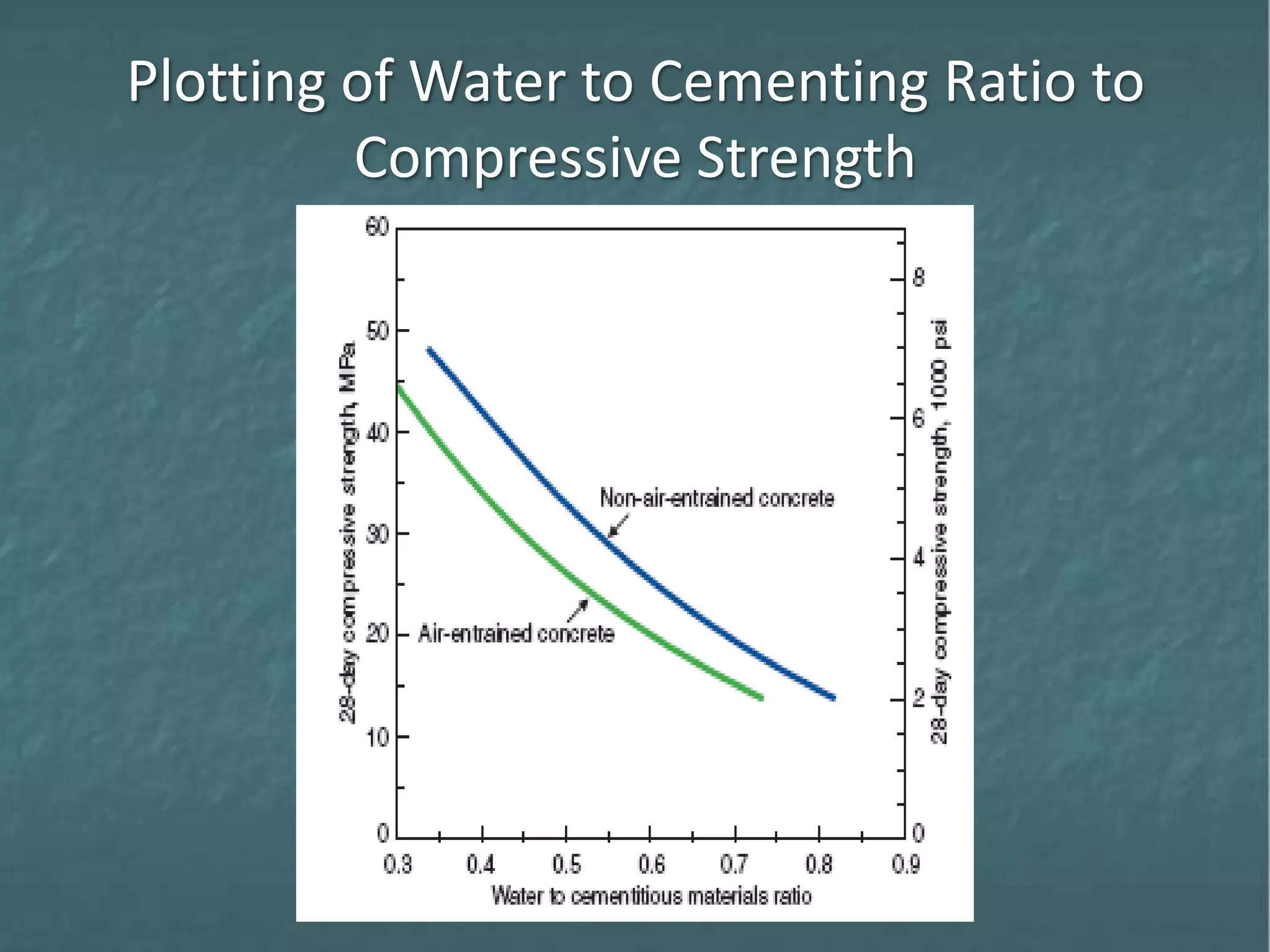

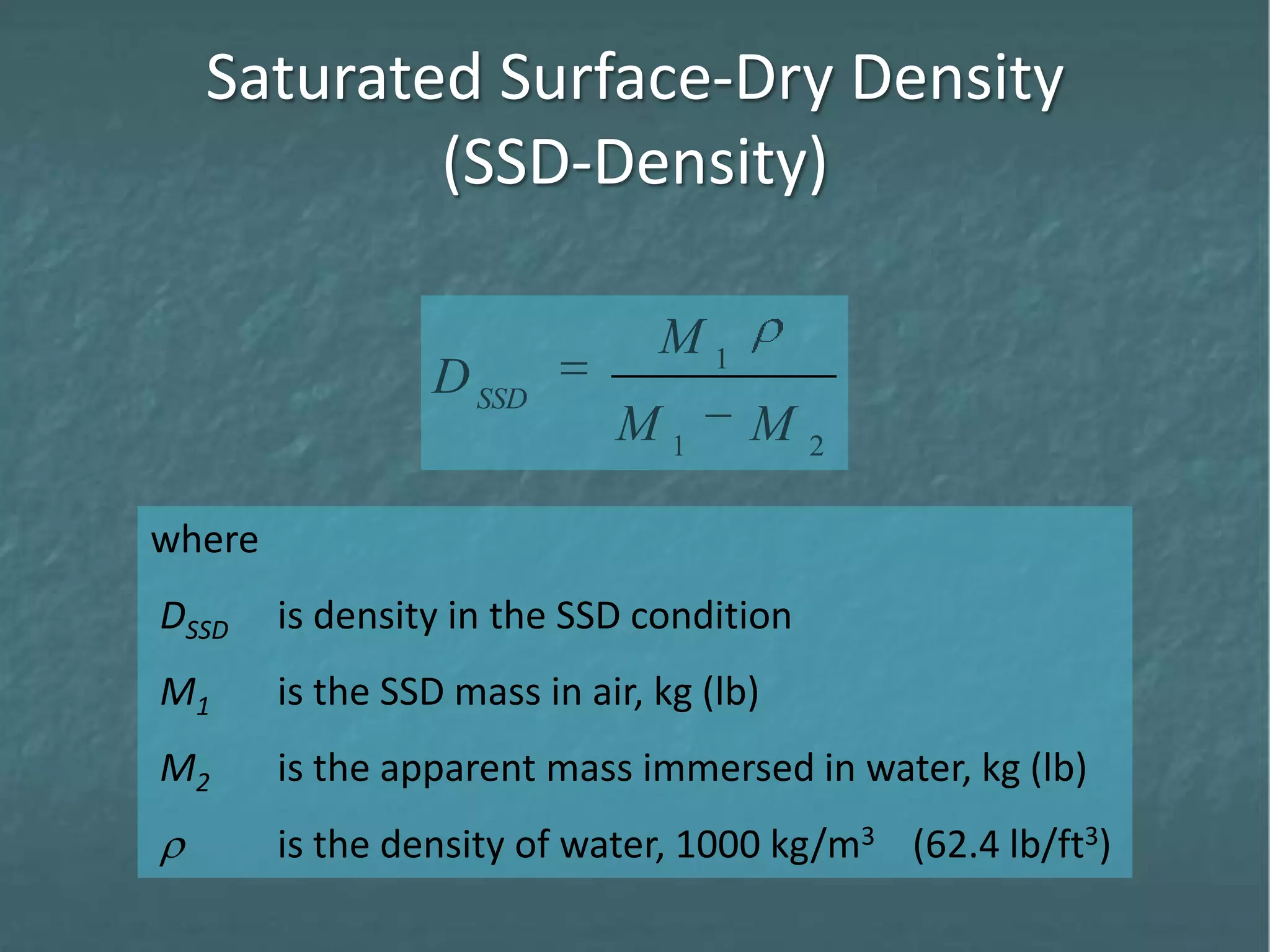

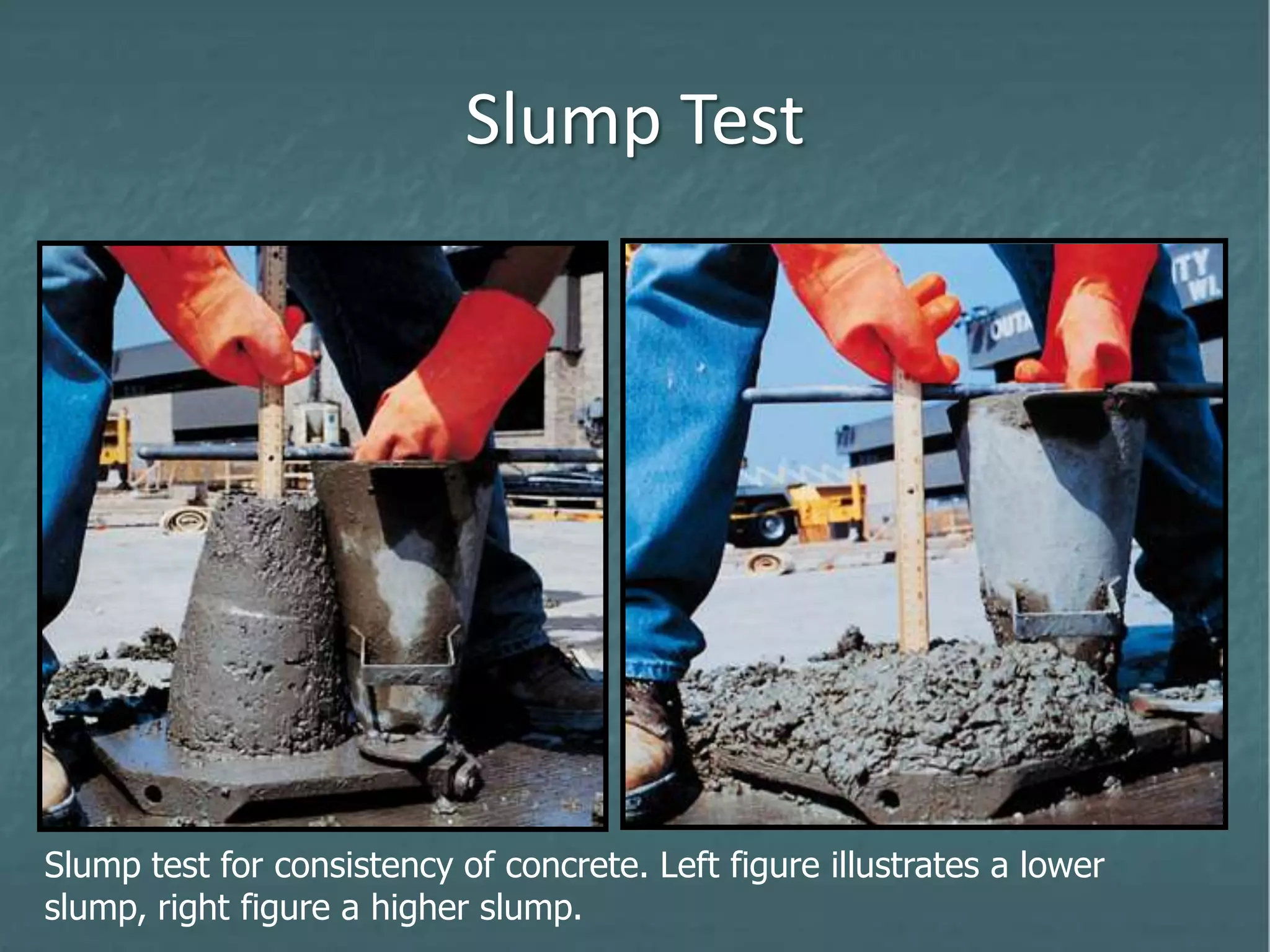

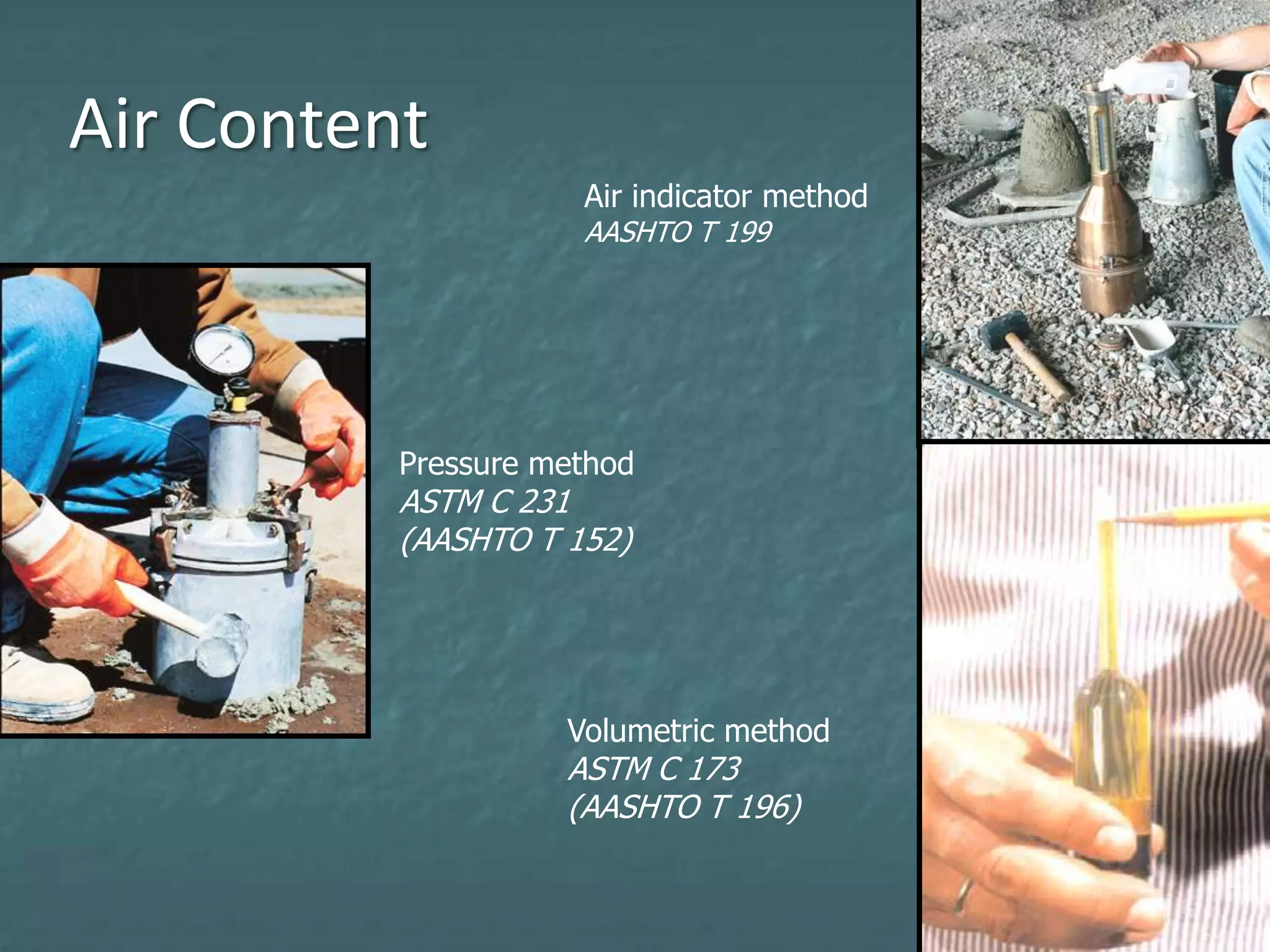

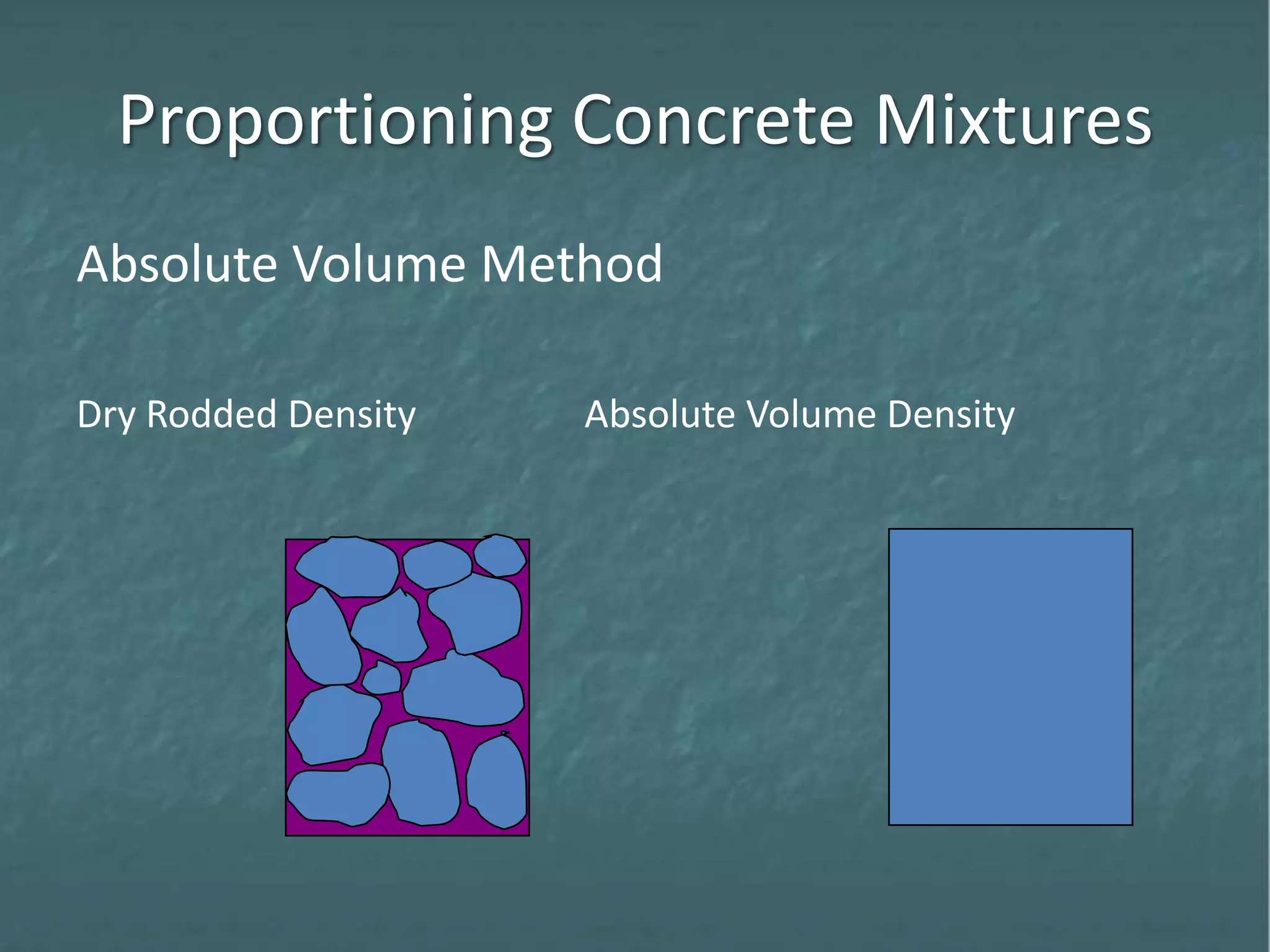

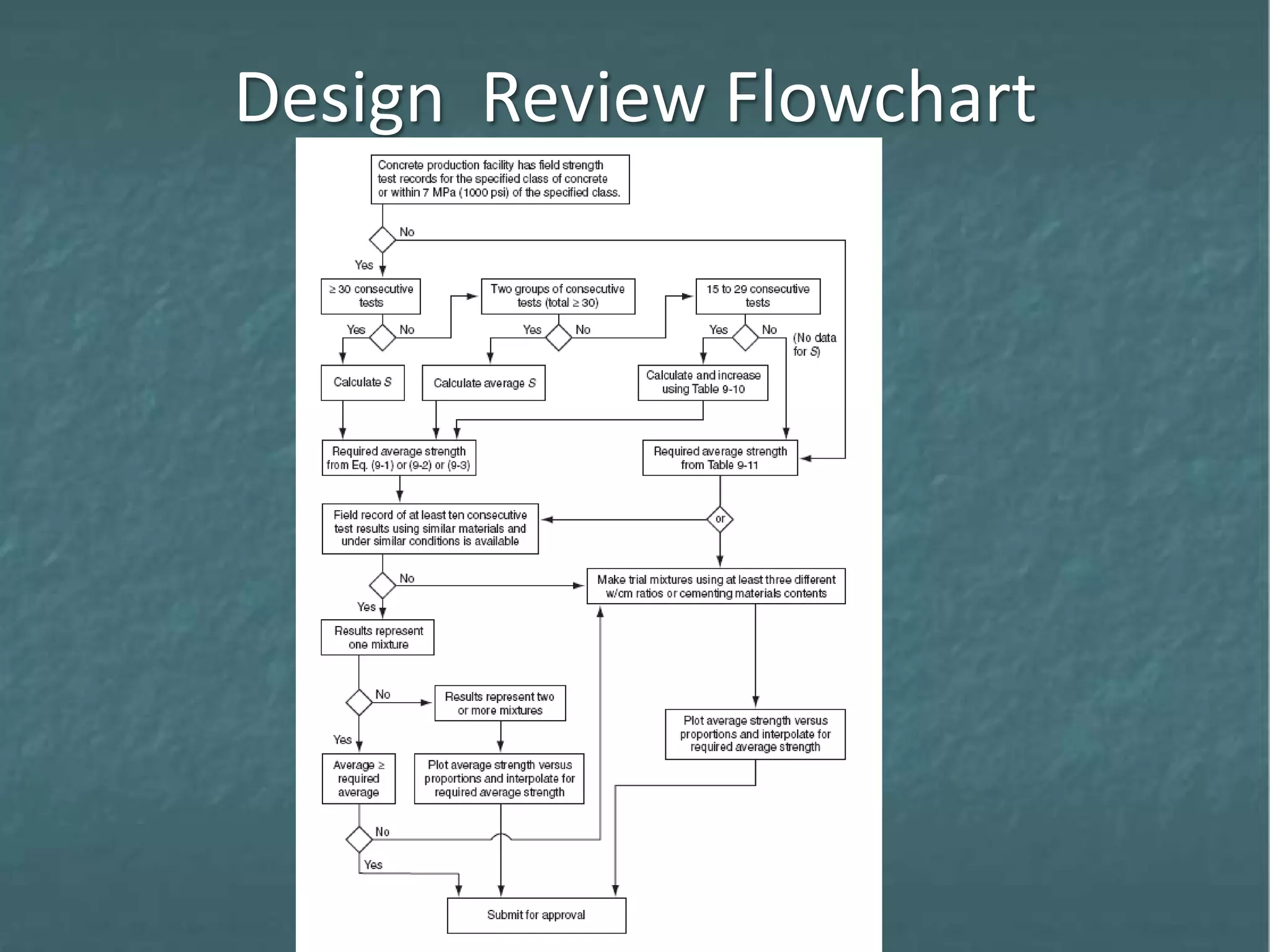

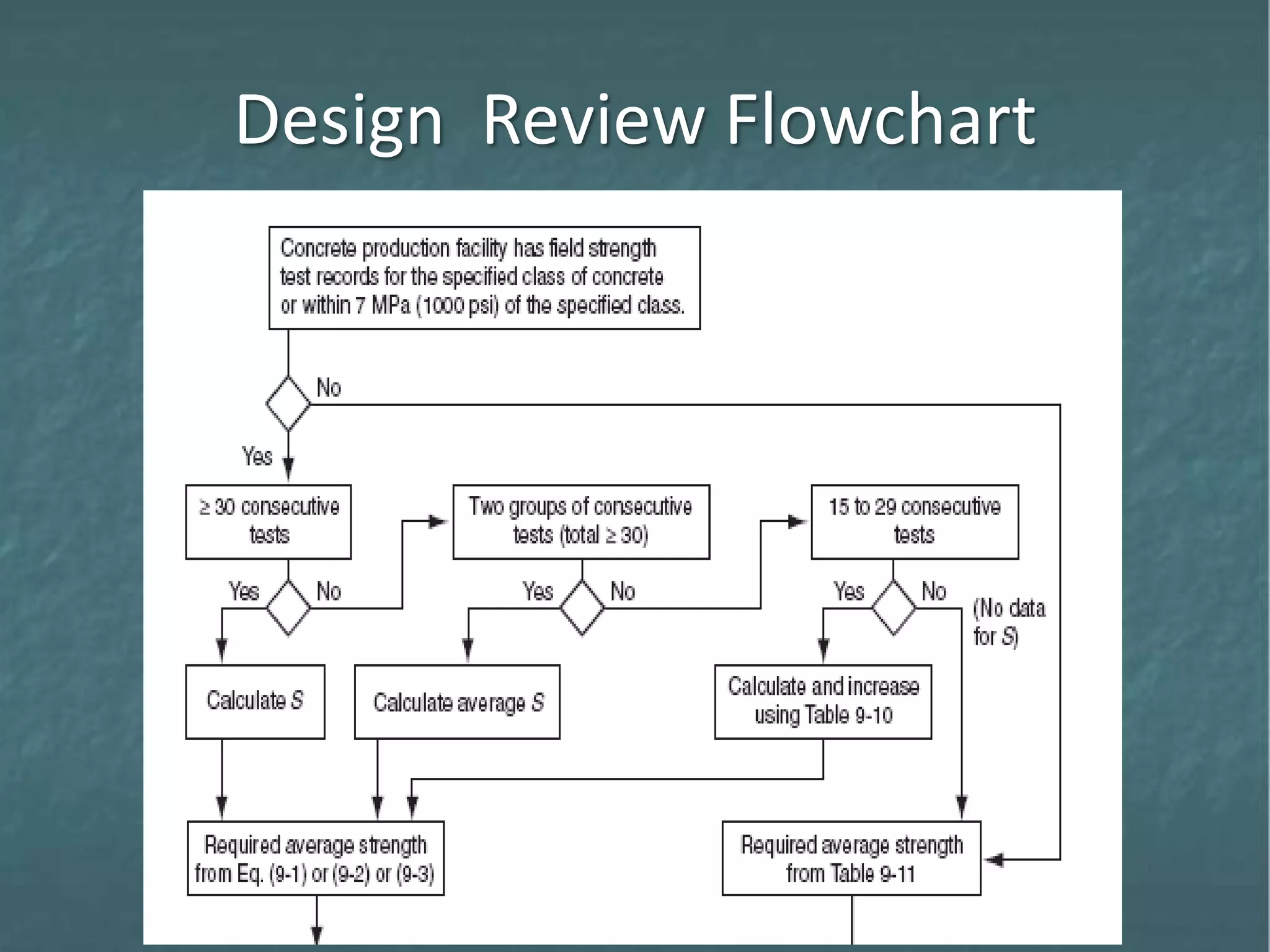

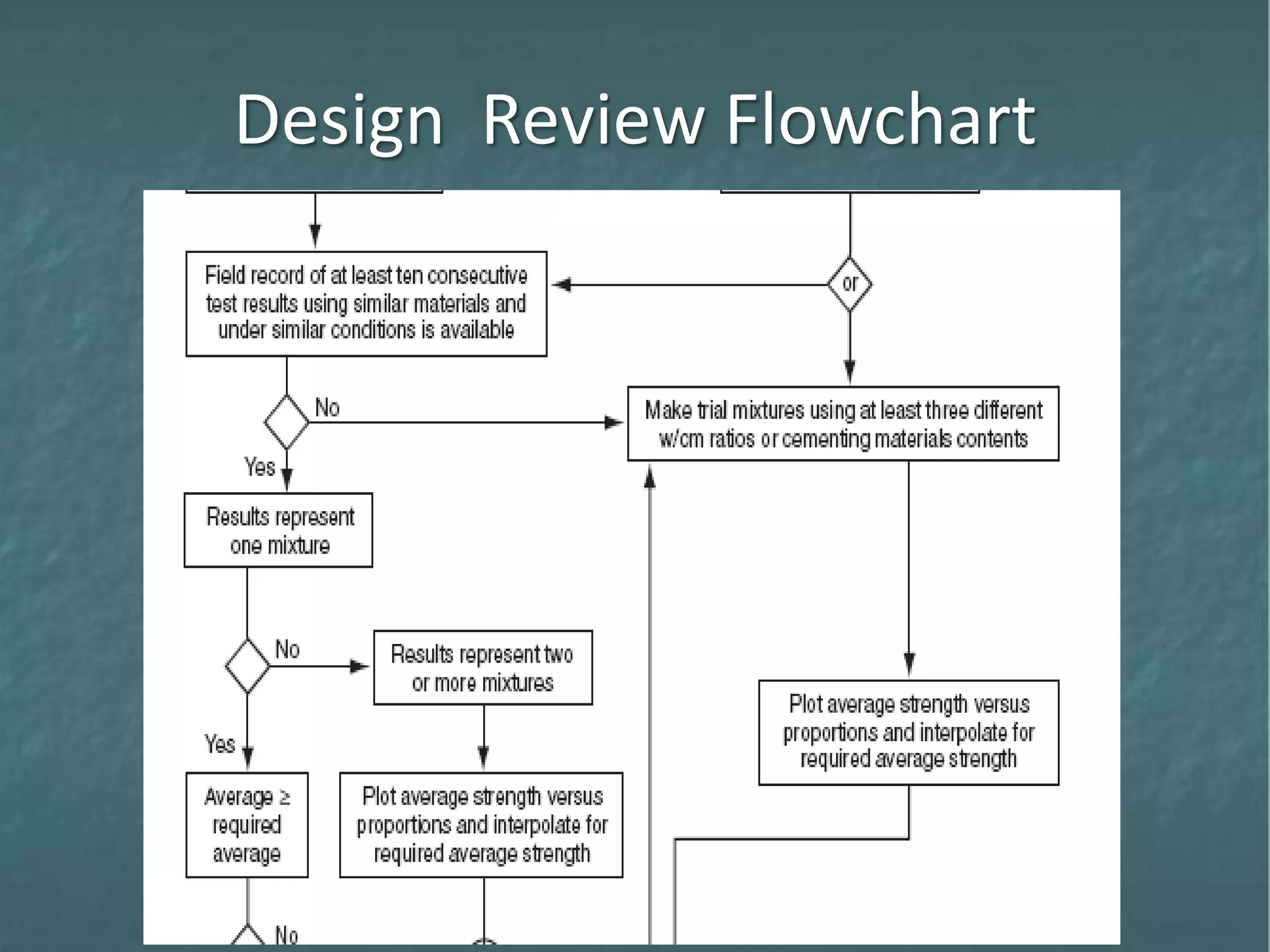

The document discusses various methods for proportioning concrete mixtures, including the water-cement ratio method, weight method, absolute volume method, and using field experience data. It provides details on using statistical analysis of strength test results and trial mixtures to establish mix designs that meet requirements for compressive strength, slump, and air content. The absolute volume method involves calculating the absolute volumes of ingredients based on their densities to determine proper mix proportions.