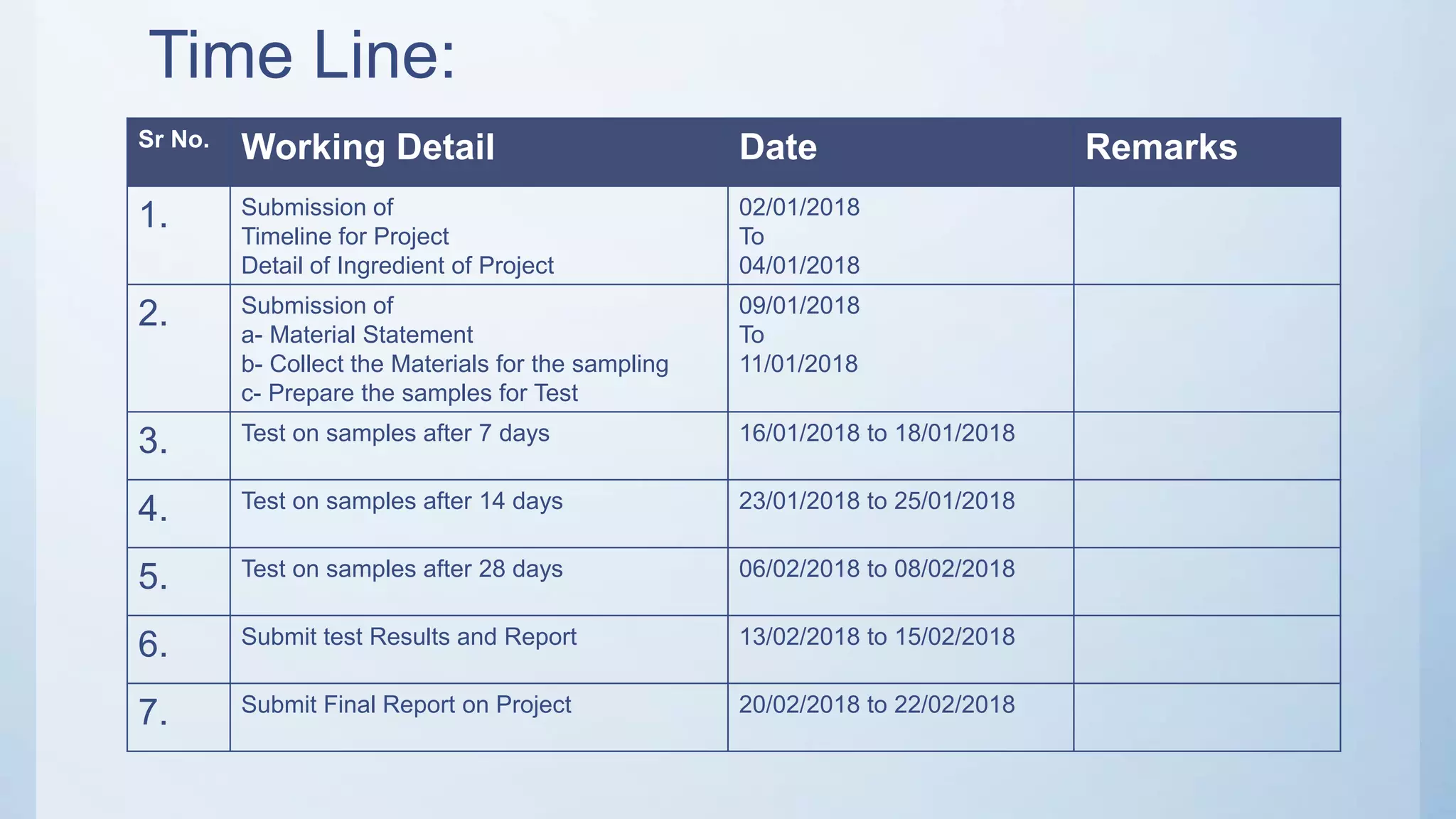

This document summarizes a study on the effect of air entrained concrete on compressive strength. It provides background on air entrained concrete, including how it contains microscopic air pockets to relieve pressure from freezing water. The document outlines the study's objectives to compare compressive strength of Portland cement concrete and air entrained concrete using different materials. It describes preparing samples with varying proportions and testing them after 7, 14, and 28 days to submit results and a final report.