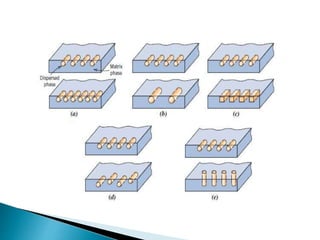

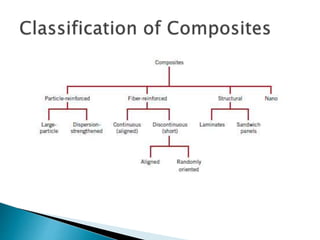

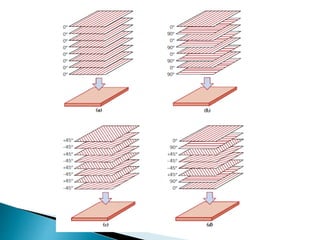

This document defines and describes different types of composite materials. It states that a composite material is made of two or more constituent materials that retain their individual properties but produce an overall material with different characteristics. The document then describes different types of composites including particle reinforced, fiber reinforced, structural, and nanocomposites. It provides examples of concrete, glass fiber reinforced polymer, carbon fiber reinforced polymer, and aramid fiber reinforced polymer composites. The document also discusses structural composites, laminar composites, and sandwich panels.