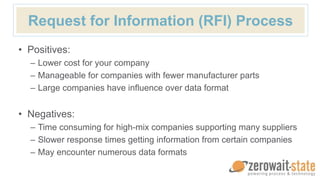

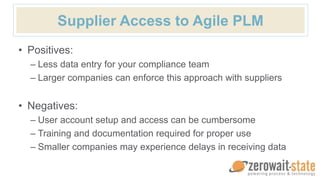

This webinar discusses automating product compliance processes using Zero Wait-State's LoadState tool and process extensions. It begins with an overview of obtaining compliance data from part research vendors or directly from suppliers. While vendors provide consistent high-quality data, it can be costly, and specialized parts may not be supported. Requesting data directly from suppliers is cheaper but slower and less consistent.

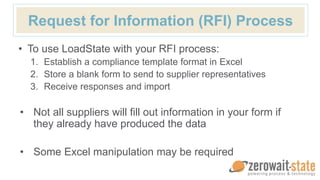

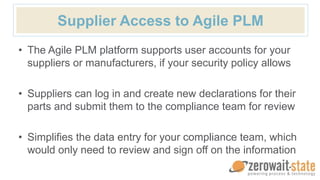

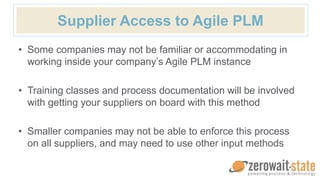

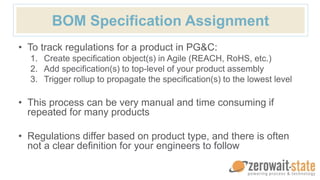

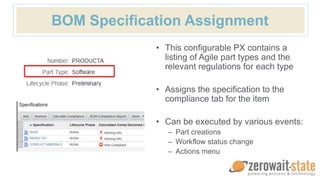

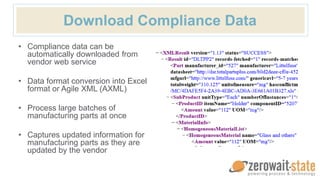

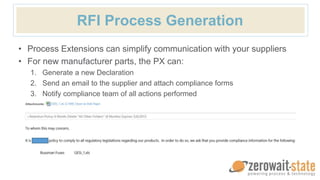

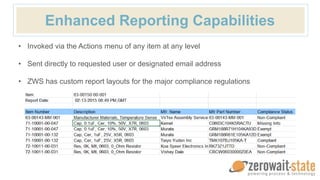

The presentation then demonstrates LoadState, which can import supplier data, perform validations, and populate declarations. Process extensions are highlighted that can assign specifications to bills of materials, download compliance data in batches, generate request for information processes, and create enhanced compliance reports. The webinar concludes with announcing an upcoming webinar on regulatory changes