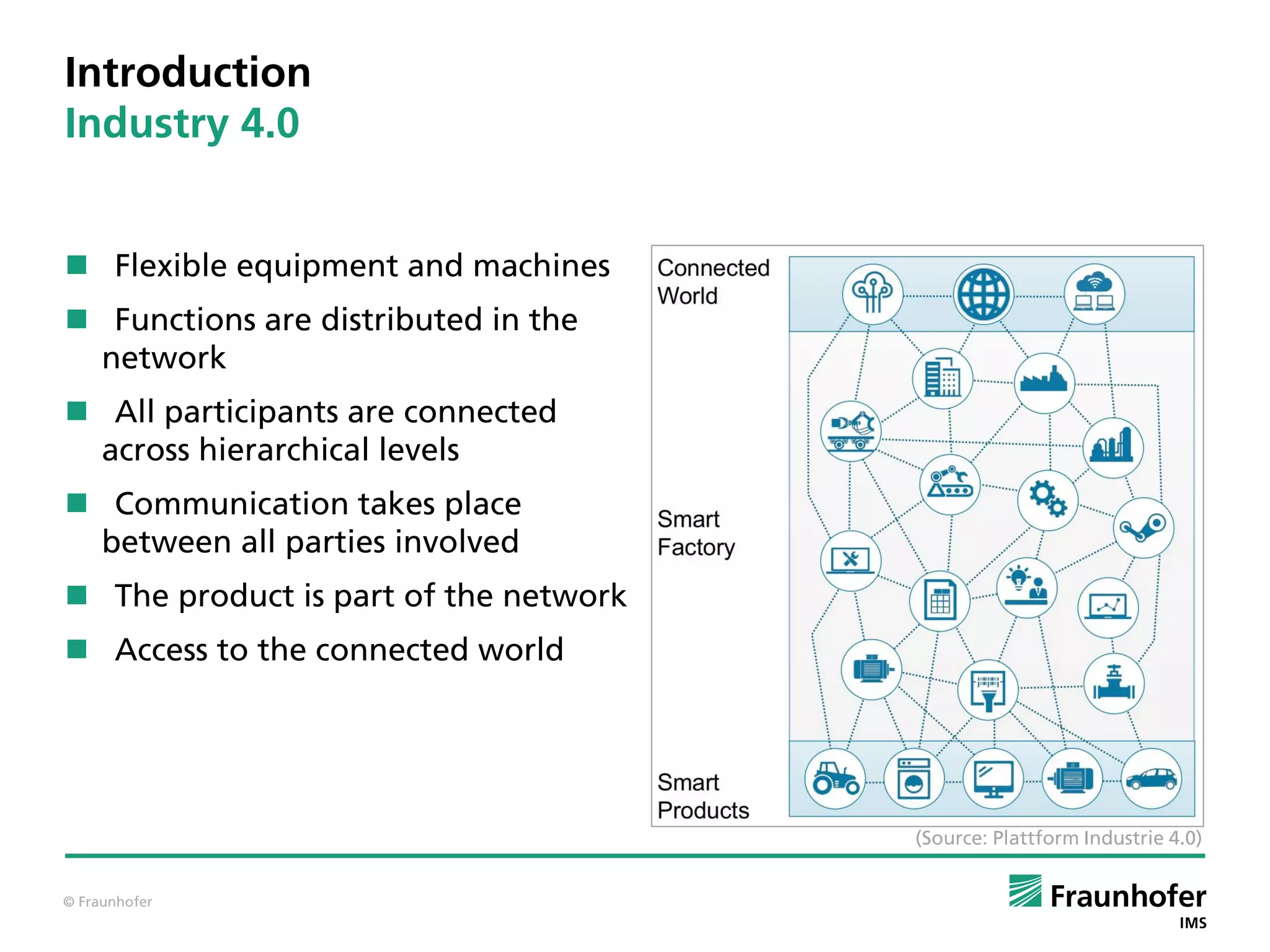

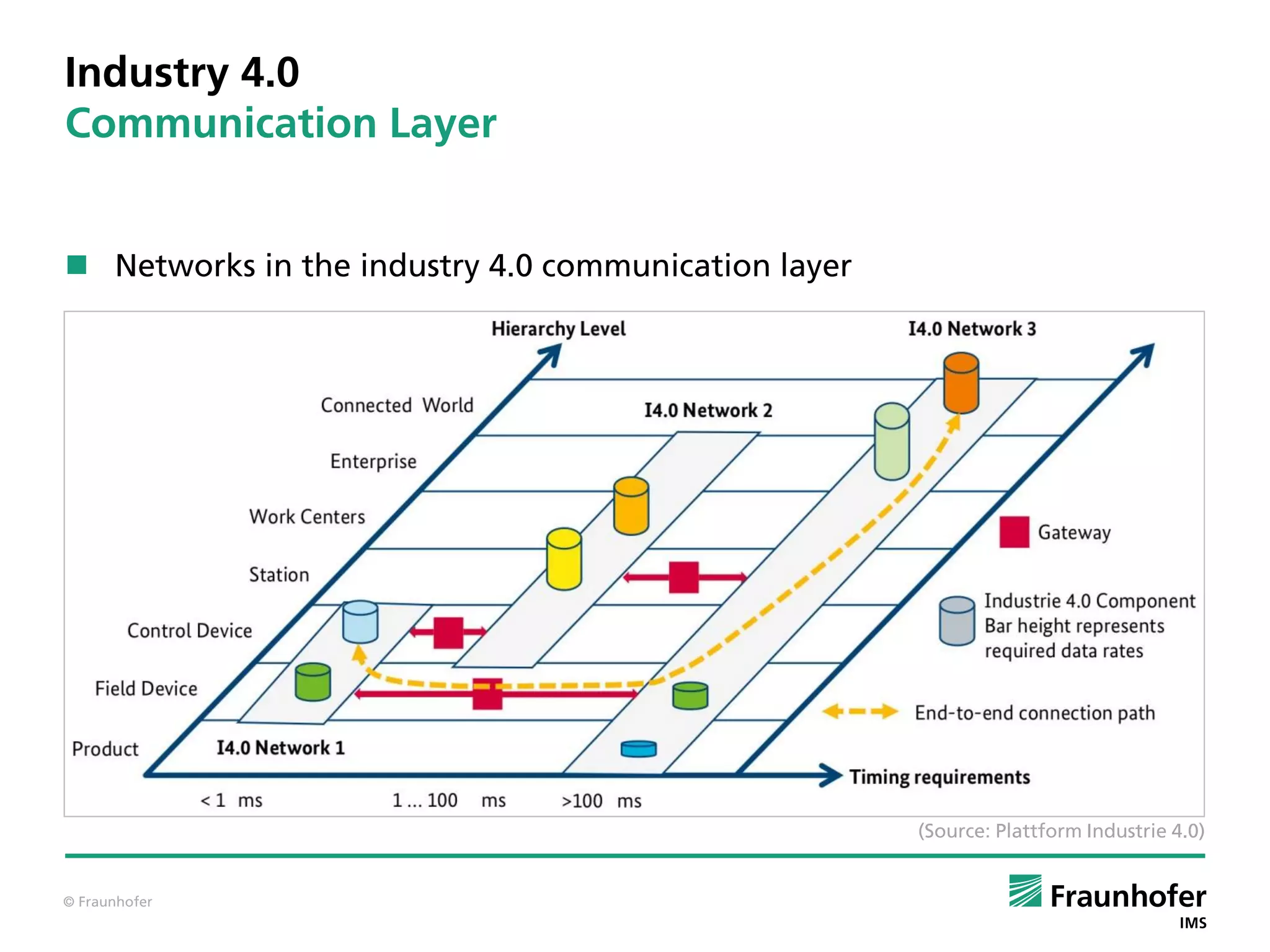

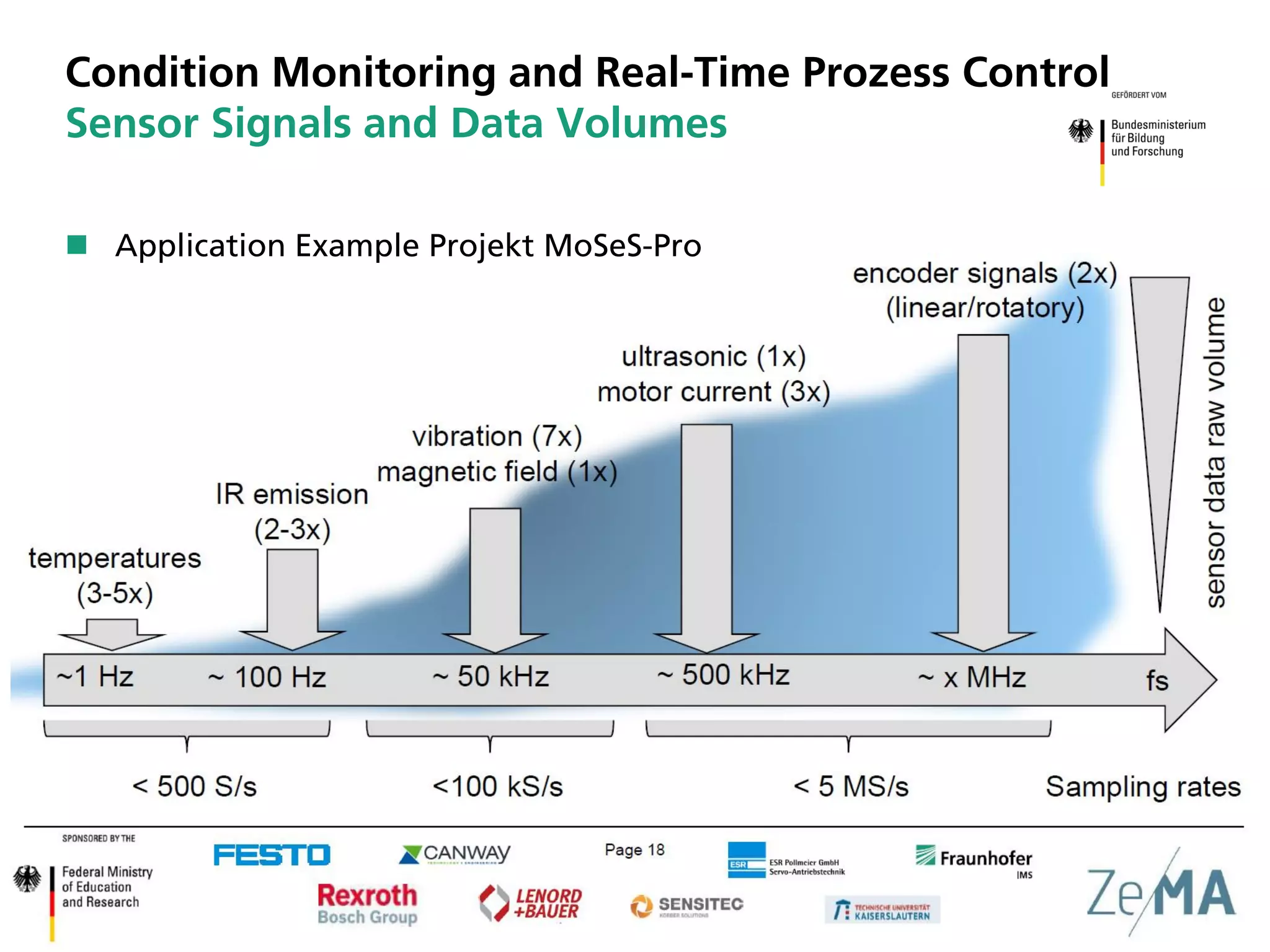

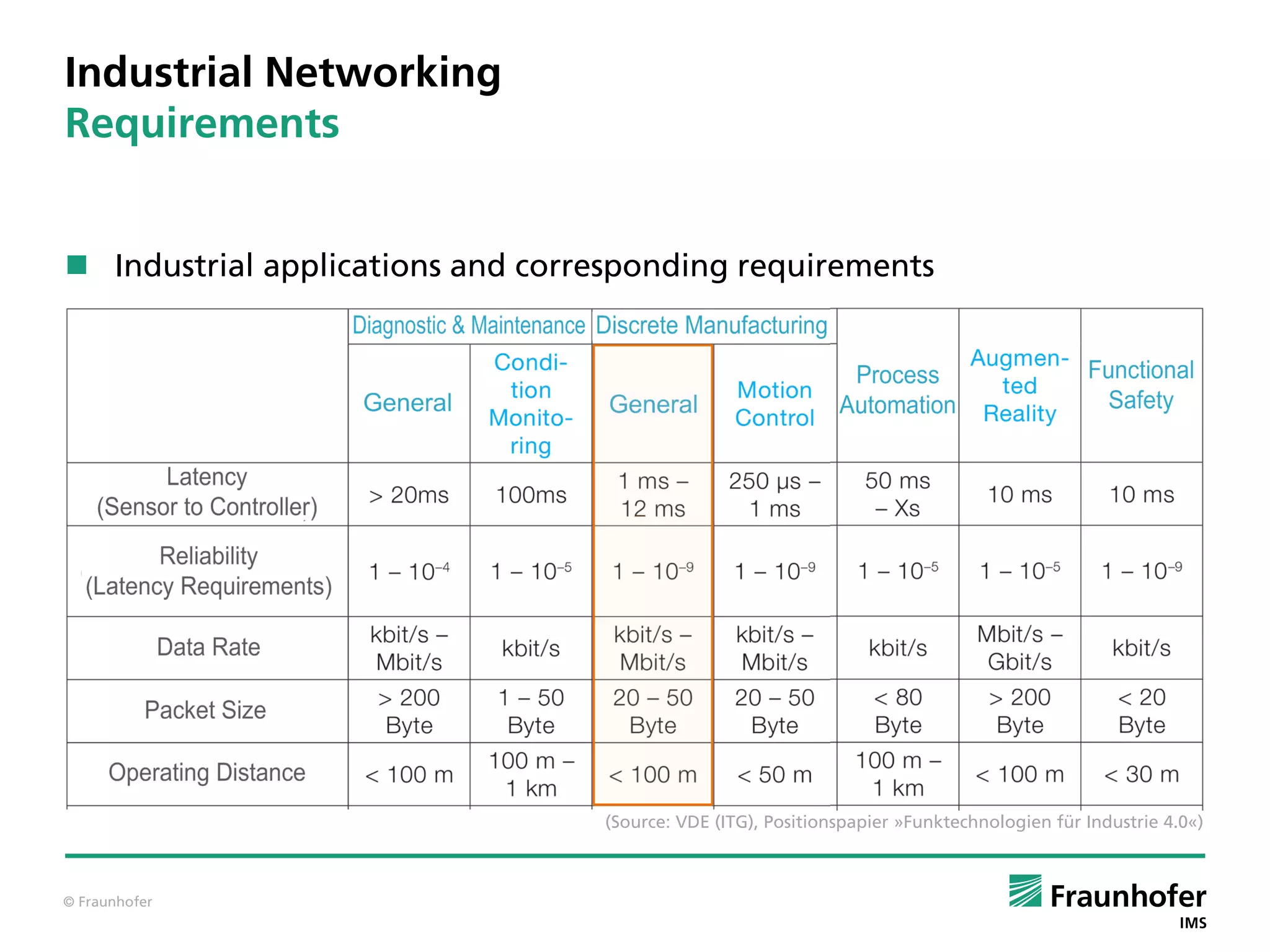

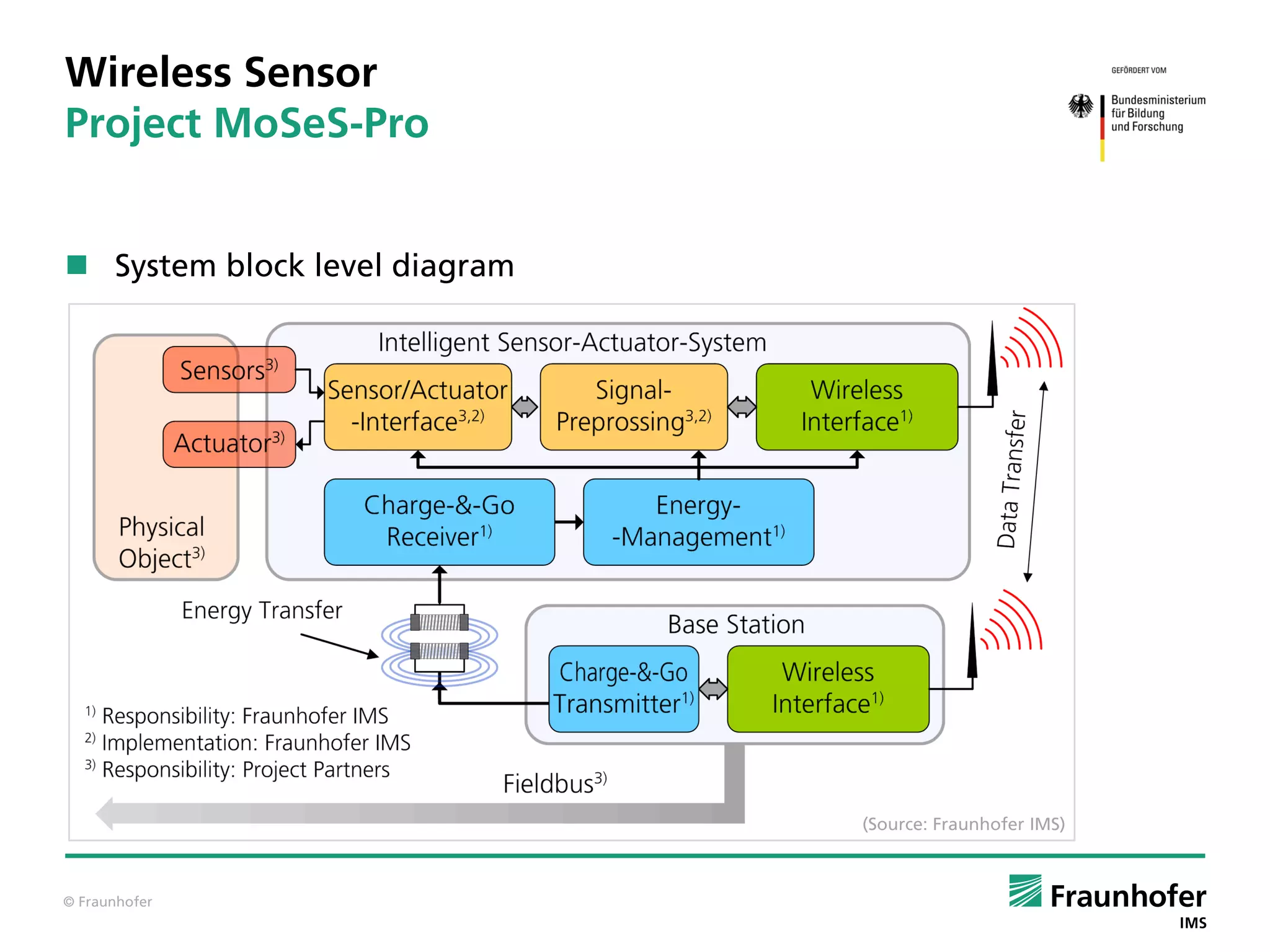

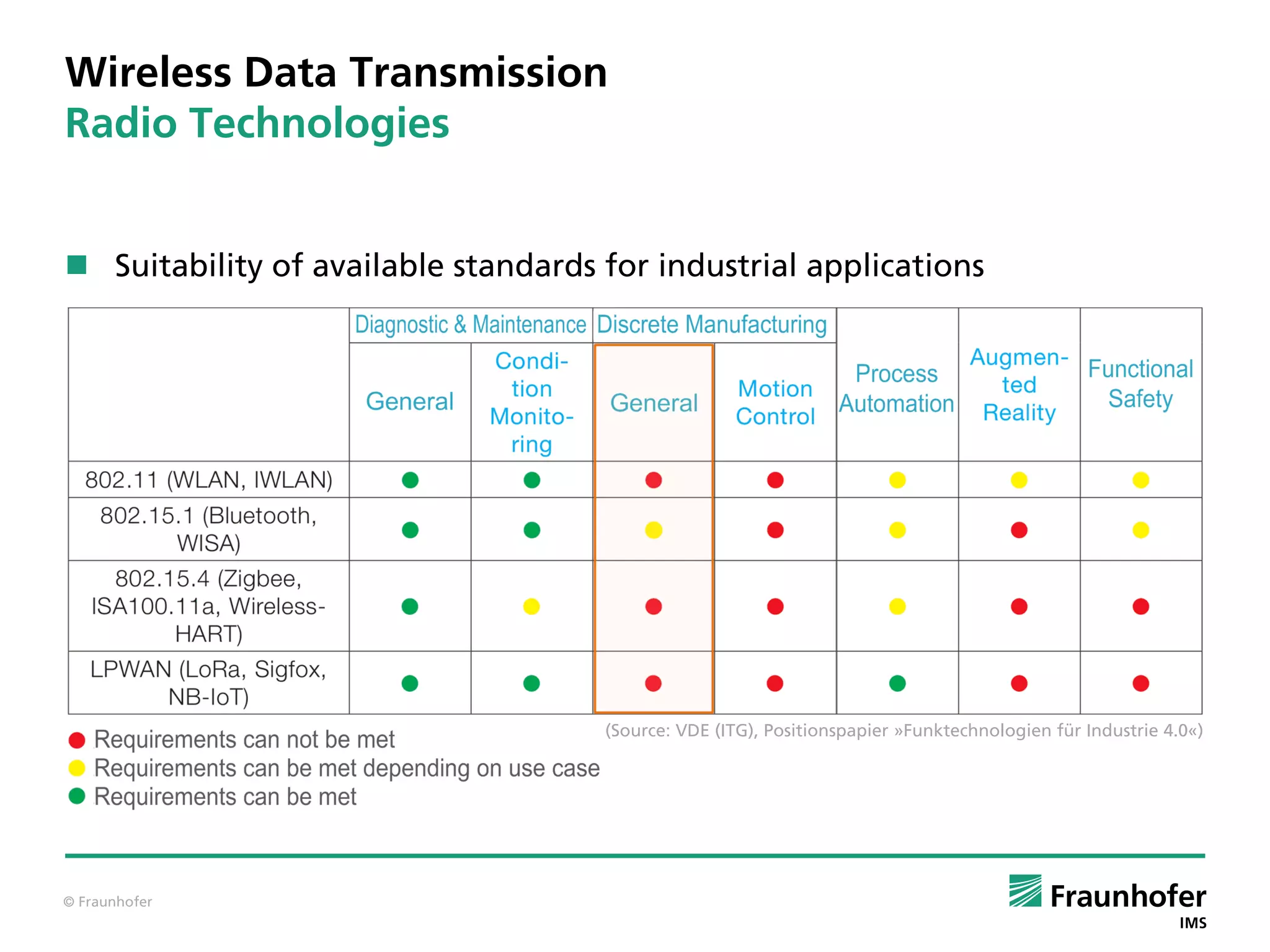

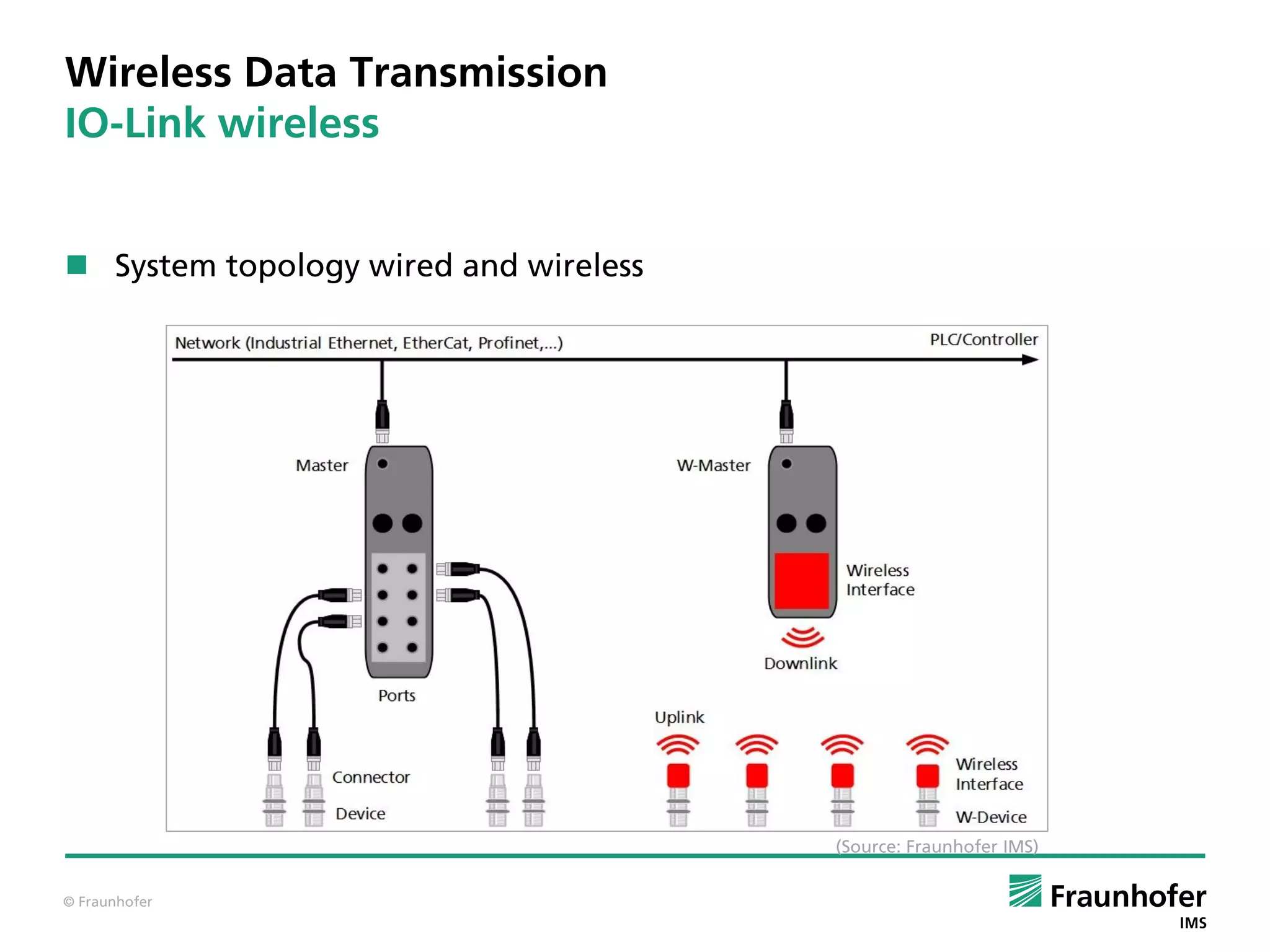

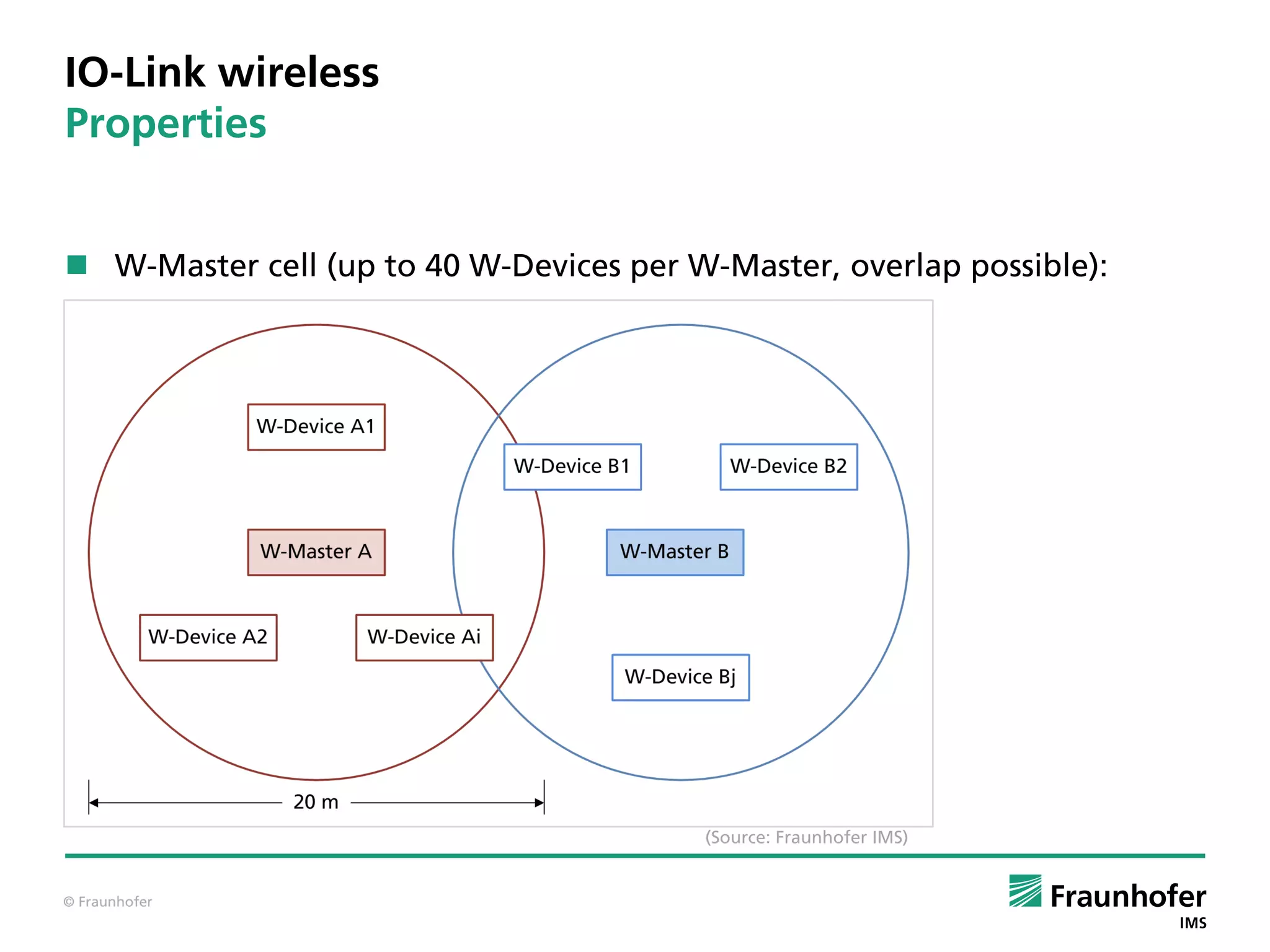

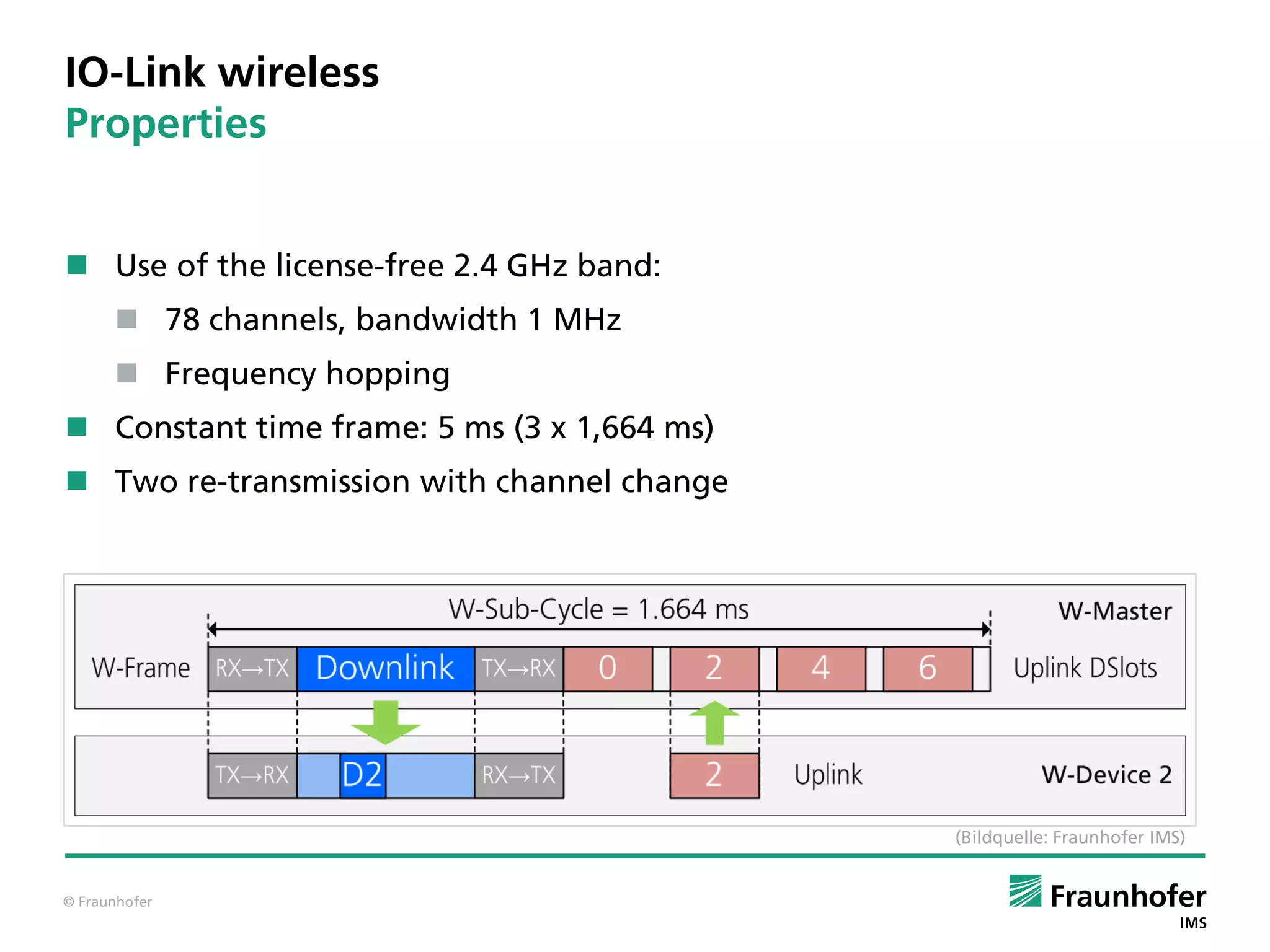

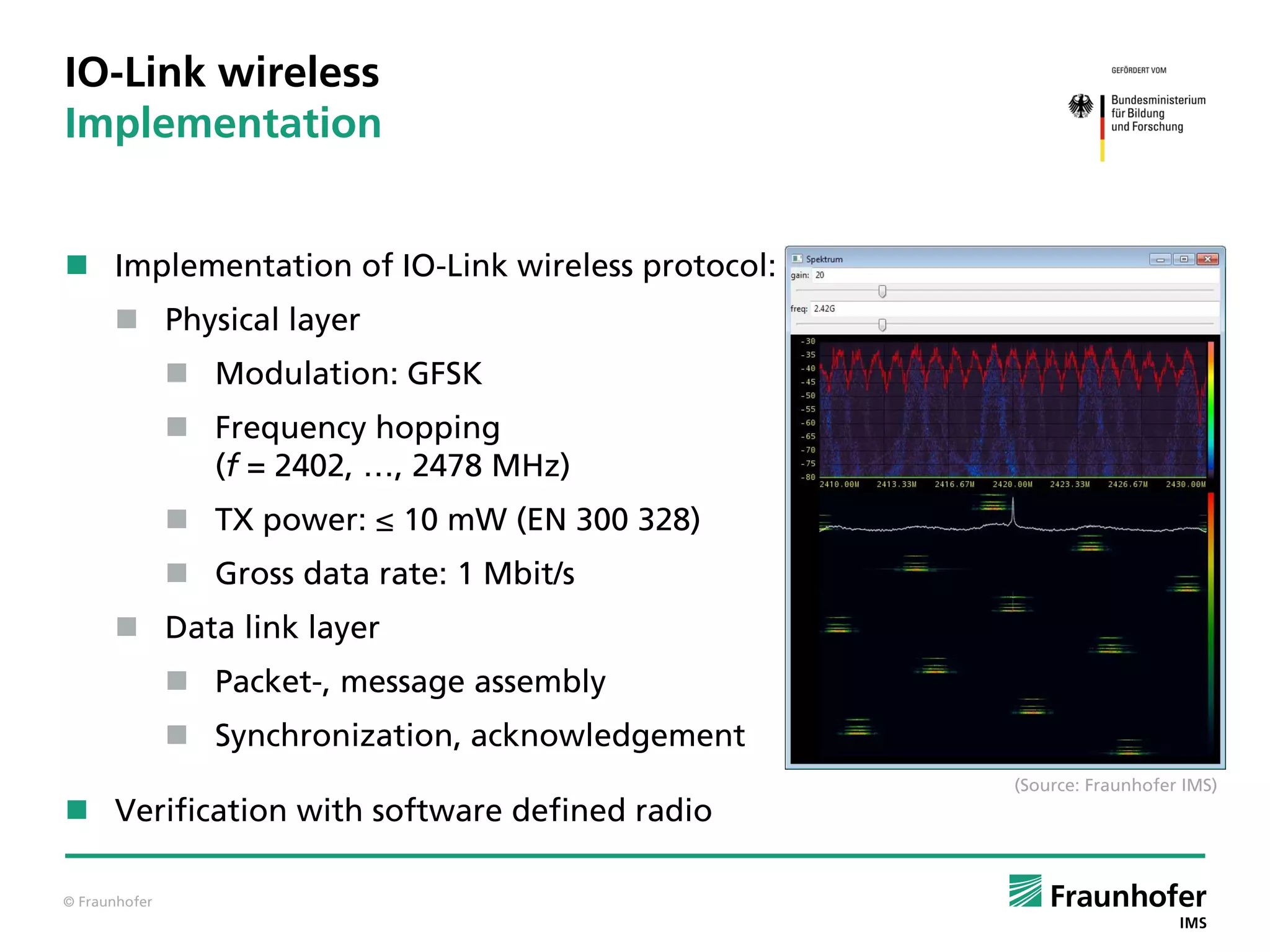

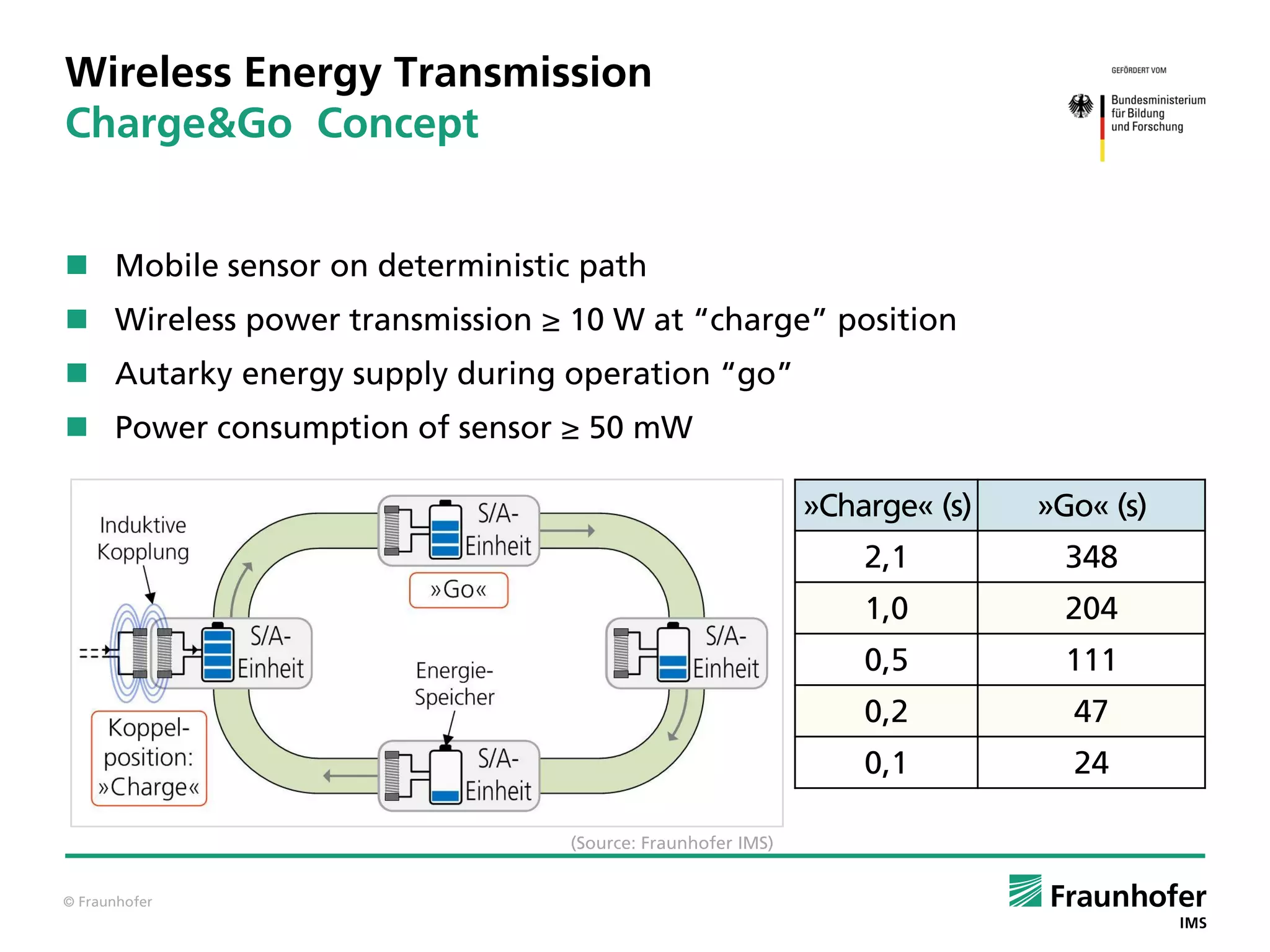

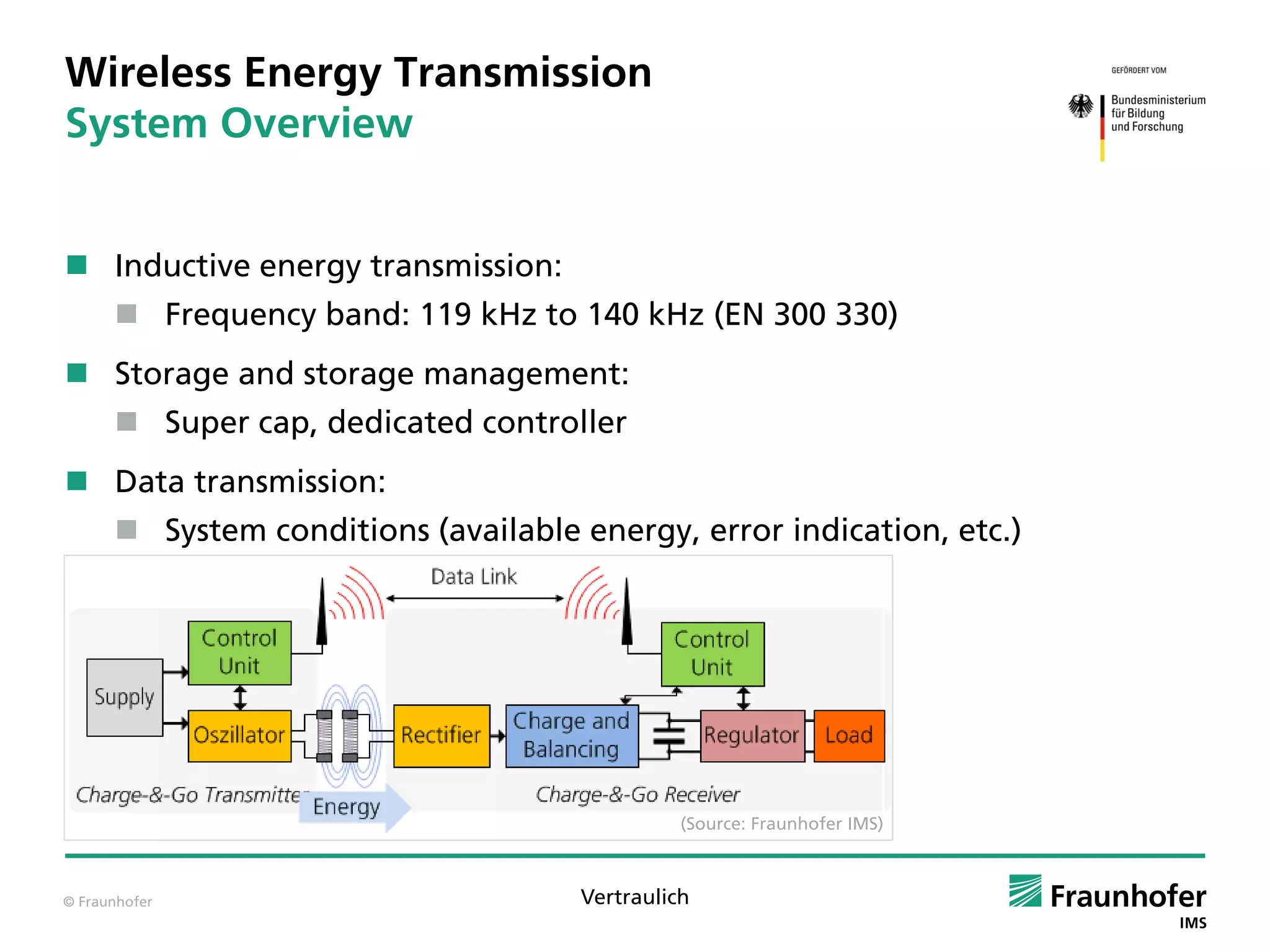

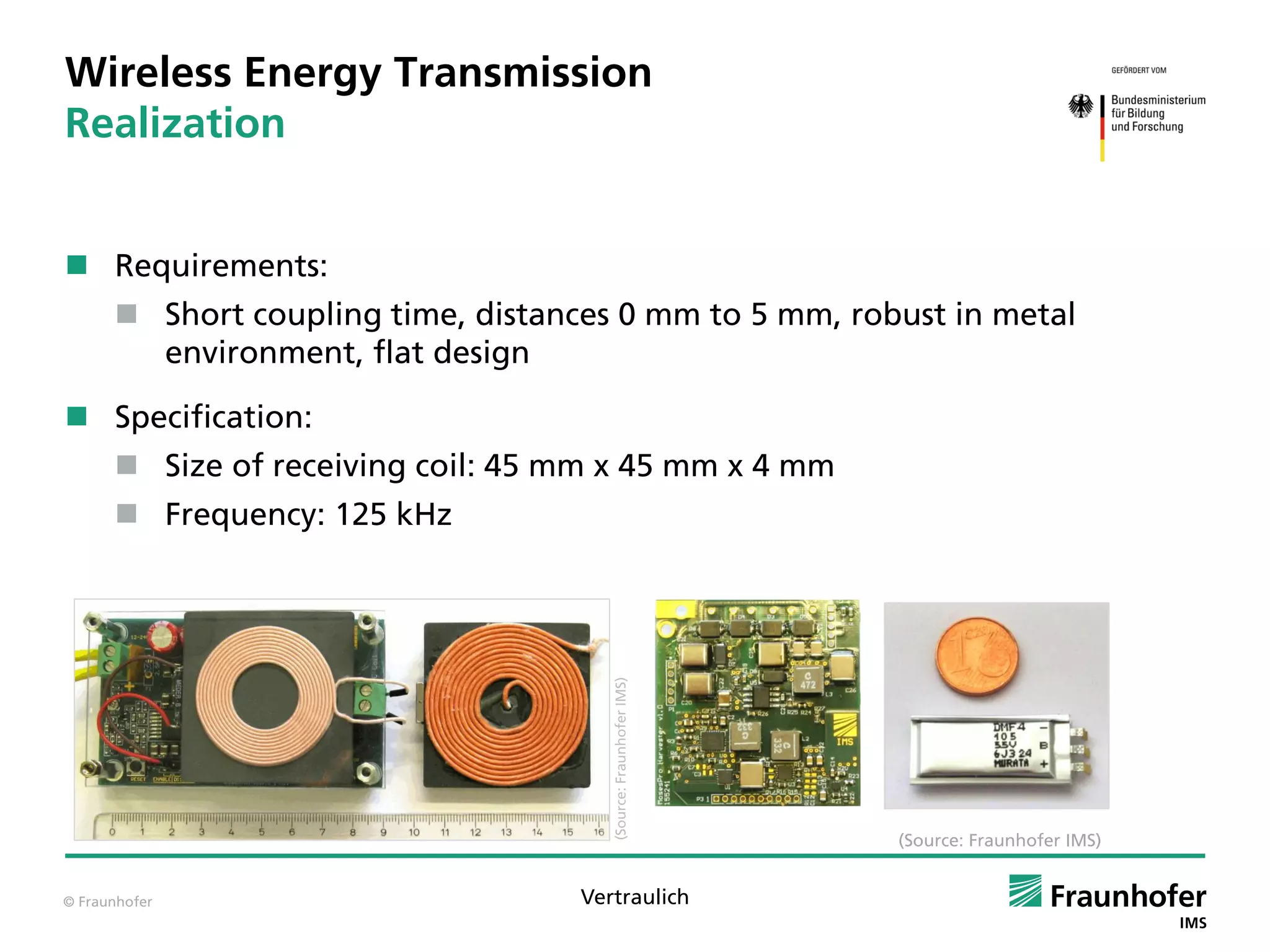

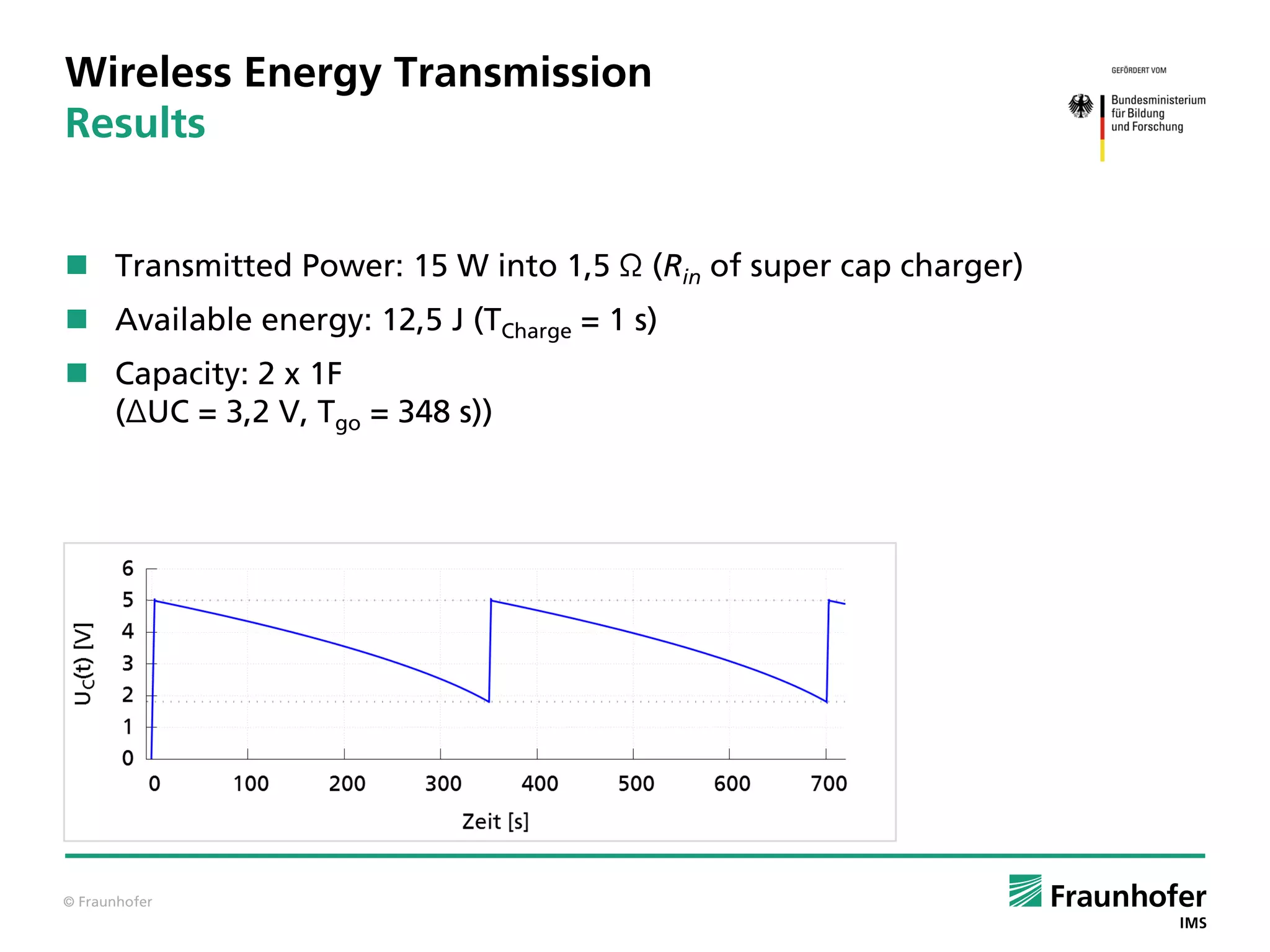

The document discusses the development of completely wireless real-time sensors for Industry 4.0 applications, highlighting the need for wireless communication due to the impracticality of cabling in harsh environments and moving machine parts. It introduces the Io-Link wireless standard, which enables reliable industrial communication and emphasizes the 'charge and go' concept for wireless energy transmission to power mobile sensors. The conclusion underscores the importance of robust wireless real-time communication for the successful implementation of smart factory technologies.