The document is a report on a combined cycle power plant located in Tripura, India. It discusses the following key points:

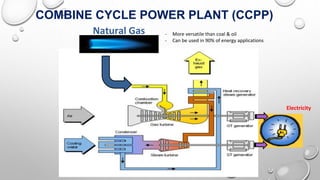

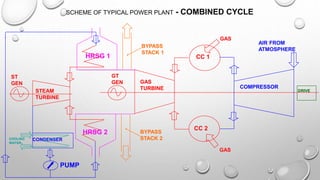

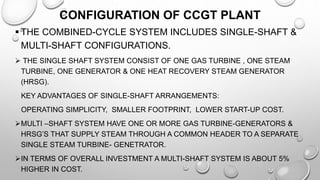

- The plant has a total capacity of 726.6 MW across two units, each with one gas turbine and one steam turbine generating 363.3 MW.

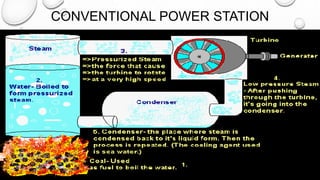

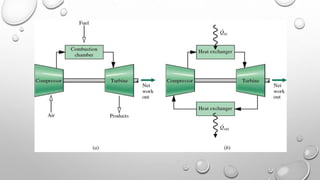

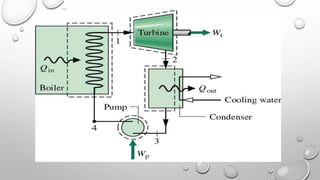

- It uses a combined cycle with both a Brayton cycle in the gas turbine and a Rankine cycle in the steam turbine to efficiently convert fuel to electricity.

- The gas turbine produces steam that is used in the steam turbine, boosting overall efficiency compared to separate gas and steam plants.