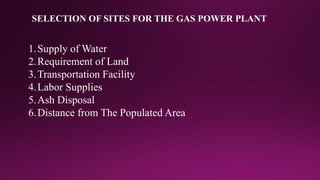

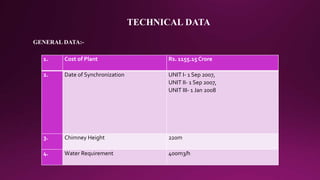

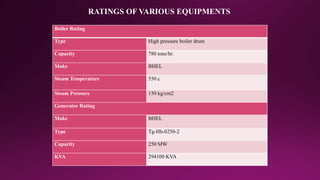

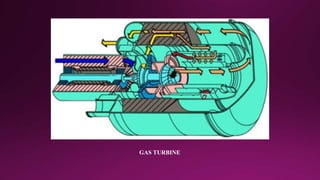

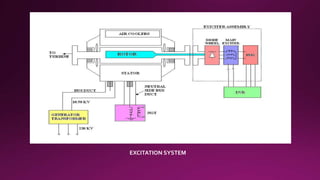

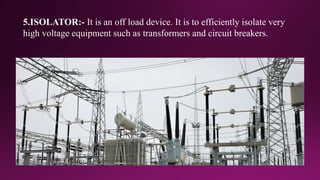

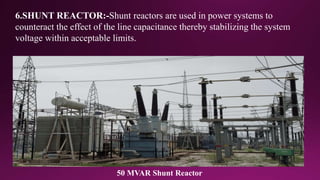

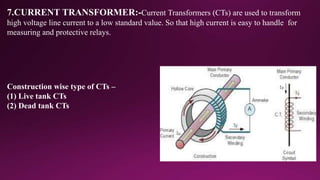

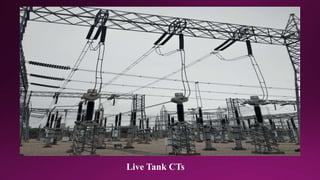

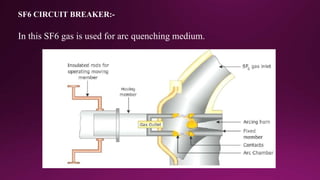

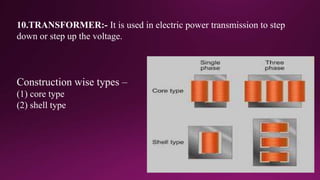

This document provides an overview of a training seminar on a summer internship at the Dholpur Combined Cycle Power Plant. It discusses the organization and various components of the power plant, including the gas turbine, heat recovery steam generator, steam turbine, condenser, turbo generator, excitation system, and 220kV switchyard. Key details are provided on the selection of the plant site, plant specifications and costs, equipment ratings, theories of operation, components and functions of the various systems. The document aims to educate interns on the technical aspects and working of the combined cycle power plant.