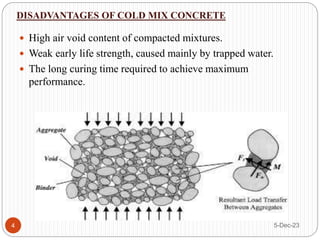

The document provides an introduction to cold mix asphalt, which is a bituminous material made by mixing cold aggregates with an asphalt emulsion and water without requiring heating. It is manufactured in pugmills that blend the materials according to a job mix formula. The document discusses the benefits of cold mix asphalt, including flexibility, resistance to damage from temperature fluctuations, moisture and rutting/cracking. It also requires no heating for construction and allows use of recycled materials. However, disadvantages include high air void content when compacted and weak early life strength due to trapped water.