Study on WMA using BFS

•Download as PPTX, PDF•

0 likes•12 views

Civil

Report

Share

Report

Share

Recommended

IRJET - To Study the effects of partially replacement of aggregate with RAP M...

https://irjet.net/archives/V7/i7/IRJET-V7I7630.pdf

Experimental Study of Partial Replacement of Fine Aggregate with Waste Materi...

The utilization of industrial and agricultural waste produced by industrial process has been the focus of waste reduction research for economical, environmental and technical reasons. This is because over 300 million tones of industrial waste are being produced per annual by agricultural and industrial process in India. The problem arising from continuous technological and industrial development is the disposal of waste material. If some of the waste materials are found suitable in concrete making not only cost of construction can be cut down, but also safe disposal of waste material can be achieved. The cement of high strength concrete is generally high which often leads to higher shrinkage and greater evaluation of neat of hydration besides increase in cost. A partial substitution of cement by an industrial waste is not only economical but also improves the properties of fresh and hardened concrete and enhance the durability characteristics besides the safe disposal of waste material thereby protecting the environment form pollution This paper deals with partial replacement of fine aggregate with the industrial waste from China Clay industries. The compressive strength, split tensile strength and flexural strength of conventional concrete and fine aggregate replaced concrete are compared and the results are tabulated.

Structural design and economic evaluation of roller compacted concrete pavement

Abut, Y., & Yildirim, S. T. (2017, October). Structural design and economic evaluation of roller compacted concrete pavement with recycled aggregates. In IOP Conference Series: Materials Science and Engineering (Vol. 245, No. 2, p. 022064). IOP Publishing.

A comparative study between traditional method and mix design with industrial...

Generally bituminous pavements face problems like cracks, rutting, depression and corrugation during it’s period of service. In this paper, we attempted various method of experiments both in traditional and mix design with bi products and therefore a comparative study has been made for extracting the finest results for the betterment of highway pavements (flexible) and for that our key elements were fly ash, geo-polymer and pieces of waste conveyer belt, added to bitumen for increasing the strength and overall capacity of pavements. Fly ash added to bitumen in the penetration test has shown improvement of 52 mm which was 40mm traditionally. Whereas, geo polymer and bitumen give the result of 74mm penetration. Ductility test with fly ash showed 37.23cm, very rigid. But geo-polymer and bitumen gave the result of 75.77cm. For increasing the bearing capacity of base soil we added pieces of waste conveyer belts and CBR value has shown the increment of 35% from 30%. So, those results convey that, the waste materials and bi products have enough quality to increase the strength and flexibility of pavements which will further help to the construction workers and engineers for maintaining and repairing flexible pavements which last long.

Recommended

IRJET - To Study the effects of partially replacement of aggregate with RAP M...

https://irjet.net/archives/V7/i7/IRJET-V7I7630.pdf

Experimental Study of Partial Replacement of Fine Aggregate with Waste Materi...

The utilization of industrial and agricultural waste produced by industrial process has been the focus of waste reduction research for economical, environmental and technical reasons. This is because over 300 million tones of industrial waste are being produced per annual by agricultural and industrial process in India. The problem arising from continuous technological and industrial development is the disposal of waste material. If some of the waste materials are found suitable in concrete making not only cost of construction can be cut down, but also safe disposal of waste material can be achieved. The cement of high strength concrete is generally high which often leads to higher shrinkage and greater evaluation of neat of hydration besides increase in cost. A partial substitution of cement by an industrial waste is not only economical but also improves the properties of fresh and hardened concrete and enhance the durability characteristics besides the safe disposal of waste material thereby protecting the environment form pollution This paper deals with partial replacement of fine aggregate with the industrial waste from China Clay industries. The compressive strength, split tensile strength and flexural strength of conventional concrete and fine aggregate replaced concrete are compared and the results are tabulated.

Structural design and economic evaluation of roller compacted concrete pavement

Abut, Y., & Yildirim, S. T. (2017, October). Structural design and economic evaluation of roller compacted concrete pavement with recycled aggregates. In IOP Conference Series: Materials Science and Engineering (Vol. 245, No. 2, p. 022064). IOP Publishing.

A comparative study between traditional method and mix design with industrial...

Generally bituminous pavements face problems like cracks, rutting, depression and corrugation during it’s period of service. In this paper, we attempted various method of experiments both in traditional and mix design with bi products and therefore a comparative study has been made for extracting the finest results for the betterment of highway pavements (flexible) and for that our key elements were fly ash, geo-polymer and pieces of waste conveyer belt, added to bitumen for increasing the strength and overall capacity of pavements. Fly ash added to bitumen in the penetration test has shown improvement of 52 mm which was 40mm traditionally. Whereas, geo polymer and bitumen give the result of 74mm penetration. Ductility test with fly ash showed 37.23cm, very rigid. But geo-polymer and bitumen gave the result of 75.77cm. For increasing the bearing capacity of base soil we added pieces of waste conveyer belts and CBR value has shown the increment of 35% from 30%. So, those results convey that, the waste materials and bi products have enough quality to increase the strength and flexibility of pavements which will further help to the construction workers and engineers for maintaining and repairing flexible pavements which last long.

G0333035040

International Journal of Humanities and Social Science Invention (IJHSSI) is an international journal intended for professionals and researchers in all fields of Humanities and Social Science. IJHSSI publishes research articles and reviews within the whole field Humanities and Social Science, new teaching methods, assessment, validation and the impact of new technologies and it will continue to provide information on the latest trends and developments in this ever-expanding subject. The publications of papers are selected through double peer reviewed to ensure originality, relevance, and readability. The articles published in our journal can be accessed online.

USE OF COPPER SLAG AS FINE AGGREGATE ‐ A CASE STUDY

Many countries are witnessing a rapid growth in the construction industry which involves the use of natural resources for the development of the inf rastructure. In order to reduce dependence on natural aggregates as the main source of aggregate in concrete,artificially manufactured aggregates and artificial aggregates generated from industrial wastes provide an alternative for the construction industry. The present study encour aged the utilization of industrial waste copper slag as replacement of natural aggregates in concre te. The results indicate that the use of copper slag in concrete increases the flexural strength of about 17% with that of control mixture. It is recommended that up to 40% of copper slag can be us e as replacement of fine aggregates.

Experimental investigations on the performance of bituminous mixes with recla...

Experimental investigations on the performance of bituminous mixes with recla...eSAT Publishing House

IJRET : International Journal of Research in Engineering and Technology is an international peer reviewed, online journal published by eSAT Publishing House for the enhancement of research in various disciplines of Engineering and Technology. The aim and scope of the journal is to provide an academic medium and an important reference for the advancement and dissemination of research results that support high-level learning, teaching and research in the fields of Engineering and Technology. We bring together Scientists, Academician, Field Engineers, Scholars and Students of related fields of Engineering and Technology.Strength Study of copper slag & Fly Ash With Replacement Of Aggregate's In Co...

https://www.irjet.net/archives/V9/i11/IRJET-V9I1156.pdf

Investigation on fine aggregate by broken tiles in concrete

This examination manages the effect on the concrete by the partial replacement of fine aggregate by ceramic

aggregate. Studies were done on a concrete, with various replacement. The impacts of various replacements 0, 10, 20, 30&40

percent of the waste ceramic tile by weight of concrete with M-30 review. At last, it was reasoned that all the strength qualities

(compressive strength, flexural strength & split tensile strength) of concrete increases with the various replacements.

investigation of low cost concrete using industrial waste as supplimentry cem...

investigation of low cost concrete using industrial waste as supplimentry cem...Abhilash Chandra Dey

presentation on investigation of low cost concrete using industrial waste as supplimentry cementitious materialStudies on quarry dust as partial replacement of fine aggregates in concrete

Natural sand is most commonly used fine aggregates

in the production of concrete possess the problem of acute

shortage in many areas. Quarry dust can be used as an economic

alternative to the natural sand. In this investigation an attempt is

made to utilize quarry dust as a partial substitute for natural

sand in producing concrete. Natural sand is replaced by Quarry

dust at an interval of 5%, 10%, 15%, 20% and 25%. Mix

proportions for M20 concrete is prepared with reference to IS:

10262-2009 and IS: 456-2000 for the study of workability.

Compressive strength and Flexural strength test results are

compared with the conventional concrete. The strengths were

obtained at the ages of 3, 7 and 28 days. Compressive and

Flexural strength increased marginally from 5% to 15%

replacement. There is a slight decrease in the corresponding

compressive and flexural strength at 20% replacement. Good

correlation was observed between compressive strength and

flexural strength. It was observed that the addition of quarry

dust that would replace the fine material at particular

proportion has displayed an enhancing effect on properties of

concrete. This investigation proves that quarry dust can be used

as a partial substitute for natural sand in preparing concrete.

IRJET- Experimental Investigation on Tannery Waste with Partial Replacement o...

https://www.irjet.net/archives/V6/i3/IRJET-V6I3785.pdf

Effects of Polymers in Bituminous Road Pavements

https://www.irjet.net/archives/V9/i11/IRJET-V9I1159.pdf

Shear strength of compacted soils using geopolymer

To assess the shear strength development of soils using geopolymer in the three-ring direct shear testing device, the results from the laboratory tests will be compared on a same graph to figure out shear strength behavior between water only and water plus 10% geopolymer.

A Laboratory Study on Acid Modified Bituminous Mixes in Comparison for Ruttin...

The rapid growth in trafficload intensity, tire pressure and traffic volume has put a hugedemand on

pavements to perform satisfactorily for the design period. A number of efforts are made in the past to

develop pavement materials that helped in attaining longer serviceability. Most of these efforts were

directed towards improving the design of bituminous mix through modified bituminous binders. In this

context an attempt is made to evaluate rutting characteristics of conventional bitumen modified with Poly

phosphoric Acid (PPA). Immersion Type Wheel Rutting Machine was used for evaluation of rutting

characteristics and is considered as one of the major critical criteria for design of pavement. Poly

phosphoric Acid (PPA) is added as modifier to virgin bitumen (VG – 30) at regular interval of 1% up to

6% to the weight of Bitumen. Bituminous Concrete of Grade-II is considered for Analysis. Slabs of

400X300X50mm are prepared for evaluation of rutting characteristics. Stability, density, voids and flow

parameters were determined using marshal test method for virgin and PPA modified mix. The result of

immersion wheel rutting explains that acid modified binders resist more rutting compared to virgin

binders. Acid modified mixes at 3% optimum performs better in rutting characteristics when tested in

laboratory for induced applied pressures, load and number of passes.

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh...

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh...MushtaqueAhmedpathan

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh PakistanSelf-compacting Concrete Study using Recycled Asphalt Pavement Incorporating ...

This research evaluates the feasibility of using recycles asphalt pavement (RAP) and supplementary cementitious materials (SCMs) in self consolidating concrete (SCC). The fresh, mechanical and durability properties of SCC mixtures were investigated. A total of sixteen mixtures divided into four groups with different RAP proportions: 0, 15, 30, and 55% replacing the natural coarse aggregate (NCA), and different percentages of supplementary cementitious materials (SCMs) replacing cement:60% Fly ash (FA), 60% ground granulated blast furnace slag (S), and 30% FA and 30% S. Constant water to cementitious materials ratio of 0.4 was maintained in all mixtures. The compressive strengths at 3, 14 and 28 days and split tensile strength at 28 days were tested. The durability characteristics including the unrestrained shrinkage strain and rapid chloride permeability (RCPT) tests were conducted. The results show that while the use of RAP reduces both the compressive and tensile strengths of SCC mixtures, it increases the resistance to chloride permeability.

An Experimental Investigation of Partial Replacement of Cement by Various Per...

Over 15 million tons of fly ash (FA) and 3 million tons of phospho-gypsum (PG) are produced every year. The utilization of these industrial by-product materials is important in terms of environmental and economical issues are concerned. The main purpose of this study is to evaluate the technical possibilities of incorporating FA and PG in production of concrete .In this study Combination of FA and PG is use as a mineral admixture with, phosphogypsum 0%., 5%,10%, 15% and fly ash is constant as 20% , Last proportion was taken PG- 5% and FA- 25%. . The compressive, tensile and flexural strength are studied by casting and testing specimens for 7, 14 and 28 days. It is shown that a part of ordinary Portland cement can be replaced with PG and FA to develop a good and hardened concrete to achieve economy; above 10% replacement of phosphogypsum and 20% replacement of F in concrete lead to drastic reduction not only in the compressive strength but also in Flexural and split tensile strength of concrete.

IRJET- Experimental Study on Partial Replacement of Cement with Fly Ash & Fin...

https://www.irjet.net/archives/V5/i8/IRJET-V5I8109.pdf

A LABORATORY STUDY ON ACID MODIFIED BITUMINOUS MIXES IN COMPARISON FOR RUTTIN...

The rapid growth in trafficload intensity, tire pressure and traffic volume has put a hugedemand on pavements to perform satisfactorily for the design period. A number of efforts are made in the past to develop pavement materials that helped in attaining longer serviceability. Most of these efforts were directed towards improving the design of bituminous mix through modified bituminous binders. In this context an attempt is made to evaluate rutting characteristics of conventional bitumen modified with Poly phosphoric Acid (PPA). Immersion Type Wheel Rutting Machine was used for evaluation of rutting characteristics and is considered as one of the major critical criteria for design of pavement. Poly phosphoric Acid (PPA) is added as modifier to virgin bitumen (VG – 30) at regular interval of 1% up to 6% to the weight of Bitumen. Bituminous Concrete of Grade-II is considered for Analysis. Slabs of 400X300X50mm are prepared for evaluation of rutting characteristics. Stability, density, voids and flow parameters were determined using marshal test method for virgin and PPA modified mix. The result of immersion wheel rutting explains that acid modified binders resist more rutting compared to virgin binders. Acid modified mixes at 3% optimum performs better in rutting characteristics when tested in laboratory for induced applied pressures, load and number of passes.

Effect of Partial Replacement of Cement by Fly Ash and Metakaolin on Concrete...

https://irjet.net/archives/V4/i6/IRJET-V4I6626.pdf

Applications and Effects of Silica Fume and Nano Silica on the Compressive St...

The application of nanotechnology in concrete adds new content to efforts to improve its performance. Due to the very small size of nanomaterials, the properties of concrete can be influenced by changing the microstructure. The study involved the use of 215 nm nano silica to increase the compressive strength of concrete. Experimental studies were performed at 0.4 , 0.7 and 1 of BC. These tests have greatly improved the strength of the early pressure and the overall pressure strength of the concrete. As the percentage of nano silica increases, an increase in strength is observed. Concrete is the material of present and future. Its widespread use in structures, from buildings to factories, bridges and airports, makes it one of the most searched materials in the 21st century. Due to rapid population explosion and the rise of technology to meet these needs, there is an urgent need to improve the strength and durability of concrete. Among the various materials used in concrete production, cement plays an important role due to its size and adhesive properties. Therefore, for the production of improved concrete, the cement humidification mechanism should be studied properly and better alternatives should be proposed. Current research is the design of M40 M30 quality of concrete. The mixtures developed to obtain more rheological properties and solid properties were studied. In this study, the cement is replaced by silica smoke and nano silica materials. In addition, it is planned to determine the number of predictions of cubes in the program. The current design of the probe is the strength of M40 and M30 quality of concrete. This thesis explore the standard optimization ratio for silica and fume to get the best compressive strength. Further this has to check for Indian standard uses for developing the demand of quality users in India. Finally this research lead us to create the console for evaluating the strength of concrete. Syed Basharat Andrabi | Er. Jagdeep Singh ""Applications and Effects of Silica Fume and Nano Silica on the Compressive Strength of Concrete"" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-3 | Issue-4 , June 2019, URL: https://www.ijtsrd.com/papers/ijtsrd25069.pdf

Paper URL: https://www.ijtsrd.com/engineering/civil-engineering/25069/applications-and-effects-of-silica-fume-and-nano-silica-on-the-compressive-strength-of-concrete/syed-basharat-andrabi

IRJET- Crumb Rubber in Concrete: Static and Dynamic Evaluation

https://www.irjet.net/archives/V5/i10/IRJET-V5I1096.pdf

一比一原版(UofT毕业证)多伦多大学毕业证成绩单如何办理

UofT毕业证原版定制【微信:176555708】【多伦多大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...Amil Baba Dawood bangali

Contact with Dawood Bhai Just call on +92322-6382012 and we'll help you. We'll solve all your problems within 12 to 24 hours and with 101% guarantee and with astrology systematic. If you want to take any personal or professional advice then also you can call us on +92322-6382012 , ONLINE LOVE PROBLEM & Other all types of Daily Life Problem's.Then CALL or WHATSAPP us on +92322-6382012 and Get all these problems solutions here by Amil Baba DAWOOD BANGALI

#vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore#blackmagicformarriage #aamilbaba #kalajadu #kalailam #taweez #wazifaexpert #jadumantar #vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore #blackmagicforlove #blackmagicformarriage #aamilbaba #kalajadu #kalailam #taweez #wazifaexpert #jadumantar #vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore #Amilbabainuk #amilbabainspain #amilbabaindubai #Amilbabainnorway #amilbabainkrachi #amilbabainlahore #amilbabaingujranwalan #amilbabainislamabad

More Related Content

Similar to Study on WMA using BFS

G0333035040

International Journal of Humanities and Social Science Invention (IJHSSI) is an international journal intended for professionals and researchers in all fields of Humanities and Social Science. IJHSSI publishes research articles and reviews within the whole field Humanities and Social Science, new teaching methods, assessment, validation and the impact of new technologies and it will continue to provide information on the latest trends and developments in this ever-expanding subject. The publications of papers are selected through double peer reviewed to ensure originality, relevance, and readability. The articles published in our journal can be accessed online.

USE OF COPPER SLAG AS FINE AGGREGATE ‐ A CASE STUDY

Many countries are witnessing a rapid growth in the construction industry which involves the use of natural resources for the development of the inf rastructure. In order to reduce dependence on natural aggregates as the main source of aggregate in concrete,artificially manufactured aggregates and artificial aggregates generated from industrial wastes provide an alternative for the construction industry. The present study encour aged the utilization of industrial waste copper slag as replacement of natural aggregates in concre te. The results indicate that the use of copper slag in concrete increases the flexural strength of about 17% with that of control mixture. It is recommended that up to 40% of copper slag can be us e as replacement of fine aggregates.

Experimental investigations on the performance of bituminous mixes with recla...

Experimental investigations on the performance of bituminous mixes with recla...eSAT Publishing House

IJRET : International Journal of Research in Engineering and Technology is an international peer reviewed, online journal published by eSAT Publishing House for the enhancement of research in various disciplines of Engineering and Technology. The aim and scope of the journal is to provide an academic medium and an important reference for the advancement and dissemination of research results that support high-level learning, teaching and research in the fields of Engineering and Technology. We bring together Scientists, Academician, Field Engineers, Scholars and Students of related fields of Engineering and Technology.Strength Study of copper slag & Fly Ash With Replacement Of Aggregate's In Co...

https://www.irjet.net/archives/V9/i11/IRJET-V9I1156.pdf

Investigation on fine aggregate by broken tiles in concrete

This examination manages the effect on the concrete by the partial replacement of fine aggregate by ceramic

aggregate. Studies were done on a concrete, with various replacement. The impacts of various replacements 0, 10, 20, 30&40

percent of the waste ceramic tile by weight of concrete with M-30 review. At last, it was reasoned that all the strength qualities

(compressive strength, flexural strength & split tensile strength) of concrete increases with the various replacements.

investigation of low cost concrete using industrial waste as supplimentry cem...

investigation of low cost concrete using industrial waste as supplimentry cem...Abhilash Chandra Dey

presentation on investigation of low cost concrete using industrial waste as supplimentry cementitious materialStudies on quarry dust as partial replacement of fine aggregates in concrete

Natural sand is most commonly used fine aggregates

in the production of concrete possess the problem of acute

shortage in many areas. Quarry dust can be used as an economic

alternative to the natural sand. In this investigation an attempt is

made to utilize quarry dust as a partial substitute for natural

sand in producing concrete. Natural sand is replaced by Quarry

dust at an interval of 5%, 10%, 15%, 20% and 25%. Mix

proportions for M20 concrete is prepared with reference to IS:

10262-2009 and IS: 456-2000 for the study of workability.

Compressive strength and Flexural strength test results are

compared with the conventional concrete. The strengths were

obtained at the ages of 3, 7 and 28 days. Compressive and

Flexural strength increased marginally from 5% to 15%

replacement. There is a slight decrease in the corresponding

compressive and flexural strength at 20% replacement. Good

correlation was observed between compressive strength and

flexural strength. It was observed that the addition of quarry

dust that would replace the fine material at particular

proportion has displayed an enhancing effect on properties of

concrete. This investigation proves that quarry dust can be used

as a partial substitute for natural sand in preparing concrete.

IRJET- Experimental Investigation on Tannery Waste with Partial Replacement o...

https://www.irjet.net/archives/V6/i3/IRJET-V6I3785.pdf

Effects of Polymers in Bituminous Road Pavements

https://www.irjet.net/archives/V9/i11/IRJET-V9I1159.pdf

Shear strength of compacted soils using geopolymer

To assess the shear strength development of soils using geopolymer in the three-ring direct shear testing device, the results from the laboratory tests will be compared on a same graph to figure out shear strength behavior between water only and water plus 10% geopolymer.

A Laboratory Study on Acid Modified Bituminous Mixes in Comparison for Ruttin...

The rapid growth in trafficload intensity, tire pressure and traffic volume has put a hugedemand on

pavements to perform satisfactorily for the design period. A number of efforts are made in the past to

develop pavement materials that helped in attaining longer serviceability. Most of these efforts were

directed towards improving the design of bituminous mix through modified bituminous binders. In this

context an attempt is made to evaluate rutting characteristics of conventional bitumen modified with Poly

phosphoric Acid (PPA). Immersion Type Wheel Rutting Machine was used for evaluation of rutting

characteristics and is considered as one of the major critical criteria for design of pavement. Poly

phosphoric Acid (PPA) is added as modifier to virgin bitumen (VG – 30) at regular interval of 1% up to

6% to the weight of Bitumen. Bituminous Concrete of Grade-II is considered for Analysis. Slabs of

400X300X50mm are prepared for evaluation of rutting characteristics. Stability, density, voids and flow

parameters were determined using marshal test method for virgin and PPA modified mix. The result of

immersion wheel rutting explains that acid modified binders resist more rutting compared to virgin

binders. Acid modified mixes at 3% optimum performs better in rutting characteristics when tested in

laboratory for induced applied pressures, load and number of passes.

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh...

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh...MushtaqueAhmedpathan

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh PakistanSelf-compacting Concrete Study using Recycled Asphalt Pavement Incorporating ...

This research evaluates the feasibility of using recycles asphalt pavement (RAP) and supplementary cementitious materials (SCMs) in self consolidating concrete (SCC). The fresh, mechanical and durability properties of SCC mixtures were investigated. A total of sixteen mixtures divided into four groups with different RAP proportions: 0, 15, 30, and 55% replacing the natural coarse aggregate (NCA), and different percentages of supplementary cementitious materials (SCMs) replacing cement:60% Fly ash (FA), 60% ground granulated blast furnace slag (S), and 30% FA and 30% S. Constant water to cementitious materials ratio of 0.4 was maintained in all mixtures. The compressive strengths at 3, 14 and 28 days and split tensile strength at 28 days were tested. The durability characteristics including the unrestrained shrinkage strain and rapid chloride permeability (RCPT) tests were conducted. The results show that while the use of RAP reduces both the compressive and tensile strengths of SCC mixtures, it increases the resistance to chloride permeability.

An Experimental Investigation of Partial Replacement of Cement by Various Per...

Over 15 million tons of fly ash (FA) and 3 million tons of phospho-gypsum (PG) are produced every year. The utilization of these industrial by-product materials is important in terms of environmental and economical issues are concerned. The main purpose of this study is to evaluate the technical possibilities of incorporating FA and PG in production of concrete .In this study Combination of FA and PG is use as a mineral admixture with, phosphogypsum 0%., 5%,10%, 15% and fly ash is constant as 20% , Last proportion was taken PG- 5% and FA- 25%. . The compressive, tensile and flexural strength are studied by casting and testing specimens for 7, 14 and 28 days. It is shown that a part of ordinary Portland cement can be replaced with PG and FA to develop a good and hardened concrete to achieve economy; above 10% replacement of phosphogypsum and 20% replacement of F in concrete lead to drastic reduction not only in the compressive strength but also in Flexural and split tensile strength of concrete.

IRJET- Experimental Study on Partial Replacement of Cement with Fly Ash & Fin...

https://www.irjet.net/archives/V5/i8/IRJET-V5I8109.pdf

A LABORATORY STUDY ON ACID MODIFIED BITUMINOUS MIXES IN COMPARISON FOR RUTTIN...

The rapid growth in trafficload intensity, tire pressure and traffic volume has put a hugedemand on pavements to perform satisfactorily for the design period. A number of efforts are made in the past to develop pavement materials that helped in attaining longer serviceability. Most of these efforts were directed towards improving the design of bituminous mix through modified bituminous binders. In this context an attempt is made to evaluate rutting characteristics of conventional bitumen modified with Poly phosphoric Acid (PPA). Immersion Type Wheel Rutting Machine was used for evaluation of rutting characteristics and is considered as one of the major critical criteria for design of pavement. Poly phosphoric Acid (PPA) is added as modifier to virgin bitumen (VG – 30) at regular interval of 1% up to 6% to the weight of Bitumen. Bituminous Concrete of Grade-II is considered for Analysis. Slabs of 400X300X50mm are prepared for evaluation of rutting characteristics. Stability, density, voids and flow parameters were determined using marshal test method for virgin and PPA modified mix. The result of immersion wheel rutting explains that acid modified binders resist more rutting compared to virgin binders. Acid modified mixes at 3% optimum performs better in rutting characteristics when tested in laboratory for induced applied pressures, load and number of passes.

Effect of Partial Replacement of Cement by Fly Ash and Metakaolin on Concrete...

https://irjet.net/archives/V4/i6/IRJET-V4I6626.pdf

Applications and Effects of Silica Fume and Nano Silica on the Compressive St...

The application of nanotechnology in concrete adds new content to efforts to improve its performance. Due to the very small size of nanomaterials, the properties of concrete can be influenced by changing the microstructure. The study involved the use of 215 nm nano silica to increase the compressive strength of concrete. Experimental studies were performed at 0.4 , 0.7 and 1 of BC. These tests have greatly improved the strength of the early pressure and the overall pressure strength of the concrete. As the percentage of nano silica increases, an increase in strength is observed. Concrete is the material of present and future. Its widespread use in structures, from buildings to factories, bridges and airports, makes it one of the most searched materials in the 21st century. Due to rapid population explosion and the rise of technology to meet these needs, there is an urgent need to improve the strength and durability of concrete. Among the various materials used in concrete production, cement plays an important role due to its size and adhesive properties. Therefore, for the production of improved concrete, the cement humidification mechanism should be studied properly and better alternatives should be proposed. Current research is the design of M40 M30 quality of concrete. The mixtures developed to obtain more rheological properties and solid properties were studied. In this study, the cement is replaced by silica smoke and nano silica materials. In addition, it is planned to determine the number of predictions of cubes in the program. The current design of the probe is the strength of M40 and M30 quality of concrete. This thesis explore the standard optimization ratio for silica and fume to get the best compressive strength. Further this has to check for Indian standard uses for developing the demand of quality users in India. Finally this research lead us to create the console for evaluating the strength of concrete. Syed Basharat Andrabi | Er. Jagdeep Singh ""Applications and Effects of Silica Fume and Nano Silica on the Compressive Strength of Concrete"" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-3 | Issue-4 , June 2019, URL: https://www.ijtsrd.com/papers/ijtsrd25069.pdf

Paper URL: https://www.ijtsrd.com/engineering/civil-engineering/25069/applications-and-effects-of-silica-fume-and-nano-silica-on-the-compressive-strength-of-concrete/syed-basharat-andrabi

IRJET- Crumb Rubber in Concrete: Static and Dynamic Evaluation

https://www.irjet.net/archives/V5/i10/IRJET-V5I1096.pdf

Similar to Study on WMA using BFS (20)

USE OF COPPER SLAG AS FINE AGGREGATE ‐ A CASE STUDY

USE OF COPPER SLAG AS FINE AGGREGATE ‐ A CASE STUDY

Experimental investigations on the performance of bituminous mixes with recla...

Experimental investigations on the performance of bituminous mixes with recla...

Strength Study of copper slag & Fly Ash With Replacement Of Aggregate's In Co...

Strength Study of copper slag & Fly Ash With Replacement Of Aggregate's In Co...

Investigation on fine aggregate by broken tiles in concrete

Investigation on fine aggregate by broken tiles in concrete

investigation of low cost concrete using industrial waste as supplimentry cem...

investigation of low cost concrete using industrial waste as supplimentry cem...

Studies on quarry dust as partial replacement of fine aggregates in concrete

Studies on quarry dust as partial replacement of fine aggregates in concrete

IRJET- Experimental Investigation on Tannery Waste with Partial Replacement o...

IRJET- Experimental Investigation on Tannery Waste with Partial Replacement o...

Shear strength of compacted soils using geopolymer

Shear strength of compacted soils using geopolymer

A Laboratory Study on Acid Modified Bituminous Mixes in Comparison for Ruttin...

A Laboratory Study on Acid Modified Bituminous Mixes in Comparison for Ruttin...

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh...

Study of Engineering Properties of Bholari Sand Kotri District Jamshoro Sindh...

Self-compacting Concrete Study using Recycled Asphalt Pavement Incorporating ...

Self-compacting Concrete Study using Recycled Asphalt Pavement Incorporating ...

An Experimental Investigation of Partial Replacement of Cement by Various Per...

An Experimental Investigation of Partial Replacement of Cement by Various Per...

IRJET- Experimental Study on Partial Replacement of Cement with Fly Ash & Fin...

IRJET- Experimental Study on Partial Replacement of Cement with Fly Ash & Fin...

A LABORATORY STUDY ON ACID MODIFIED BITUMINOUS MIXES IN COMPARISON FOR RUTTIN...

A LABORATORY STUDY ON ACID MODIFIED BITUMINOUS MIXES IN COMPARISON FOR RUTTIN...

Effect of Partial Replacement of Cement by Fly Ash and Metakaolin on Concrete...

Effect of Partial Replacement of Cement by Fly Ash and Metakaolin on Concrete...

Applications and Effects of Silica Fume and Nano Silica on the Compressive St...

Applications and Effects of Silica Fume and Nano Silica on the Compressive St...

IRJET- Crumb Rubber in Concrete: Static and Dynamic Evaluation

IRJET- Crumb Rubber in Concrete: Static and Dynamic Evaluation

Recently uploaded

一比一原版(UofT毕业证)多伦多大学毕业证成绩单如何办理

UofT毕业证原版定制【微信:176555708】【多伦多大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...Amil Baba Dawood bangali

Contact with Dawood Bhai Just call on +92322-6382012 and we'll help you. We'll solve all your problems within 12 to 24 hours and with 101% guarantee and with astrology systematic. If you want to take any personal or professional advice then also you can call us on +92322-6382012 , ONLINE LOVE PROBLEM & Other all types of Daily Life Problem's.Then CALL or WHATSAPP us on +92322-6382012 and Get all these problems solutions here by Amil Baba DAWOOD BANGALI

#vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore#blackmagicformarriage #aamilbaba #kalajadu #kalailam #taweez #wazifaexpert #jadumantar #vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore #blackmagicforlove #blackmagicformarriage #aamilbaba #kalajadu #kalailam #taweez #wazifaexpert #jadumantar #vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore #Amilbabainuk #amilbabainspain #amilbabaindubai #Amilbabainnorway #amilbabainkrachi #amilbabainlahore #amilbabaingujranwalan #amilbabainislamabad

HYDROPOWER - Hydroelectric power generation

Overview of the fundamental roles in Hydropower generation and the components involved in wider Electrical Engineering.

This paper presents the design and construction of hydroelectric dams from the hydrologist’s survey of the valley before construction, all aspects and involved disciplines, fluid dynamics, structural engineering, generation and mains frequency regulation to the very transmission of power through the network in the United Kingdom.

Author: Robbie Edward Sayers

Collaborators and co editors: Charlie Sims and Connor Healey.

(C) 2024 Robbie E. Sayers

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Advancements in technology unveil a myriad of electrical and electronic breakthroughs geared towards efficiently harnessing limited resources to meet human energy demands. The optimization of hybrid solar PV panels and pumped hydro energy supply systems plays a pivotal role in utilizing natural resources effectively. This initiative not only benefits humanity but also fosters environmental sustainability. The study investigated the design optimization of these hybrid systems, focusing on understanding solar radiation patterns, identifying geographical influences on solar radiation, formulating a mathematical model for system optimization, and determining the optimal configuration of PV panels and pumped hydro storage. Through a comparative analysis approach and eight weeks of data collection, the study addressed key research questions related to solar radiation patterns and optimal system design. The findings highlighted regions with heightened solar radiation levels, showcasing substantial potential for power generation and emphasizing the system's efficiency. Optimizing system design significantly boosted power generation, promoted renewable energy utilization, and enhanced energy storage capacity. The study underscored the benefits of optimizing hybrid solar PV panels and pumped hydro energy supply systems for sustainable energy usage. Optimizing the design of solar PV panels and pumped hydro energy supply systems as examined across diverse climatic conditions in a developing country, not only enhances power generation but also improves the integration of renewable energy sources and boosts energy storage capacities, particularly beneficial for less economically prosperous regions. Additionally, the study provides valuable insights for advancing energy research in economically viable areas. Recommendations included conducting site-specific assessments, utilizing advanced modeling tools, implementing regular maintenance protocols, and enhancing communication among system components.

CFD Simulation of By-pass Flow in a HRSG module by R&R Consult.pptx

CFD analysis is incredibly effective at solving mysteries and improving the performance of complex systems!

Here's a great example: At a large natural gas-fired power plant, where they use waste heat to generate steam and energy, they were puzzled that their boiler wasn't producing as much steam as expected.

R&R and Tetra Engineering Group Inc. were asked to solve the issue with reduced steam production.

An inspection had shown that a significant amount of hot flue gas was bypassing the boiler tubes, where the heat was supposed to be transferred.

R&R Consult conducted a CFD analysis, which revealed that 6.3% of the flue gas was bypassing the boiler tubes without transferring heat. The analysis also showed that the flue gas was instead being directed along the sides of the boiler and between the modules that were supposed to capture the heat. This was the cause of the reduced performance.

Based on our results, Tetra Engineering installed covering plates to reduce the bypass flow. This improved the boiler's performance and increased electricity production.

It is always satisfying when we can help solve complex challenges like this. Do your systems also need a check-up or optimization? Give us a call!

Work done in cooperation with James Malloy and David Moelling from Tetra Engineering.

More examples of our work https://www.r-r-consult.dk/en/cases-en/

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Governing Equations for Fundamental Aerodynamics

Cosmetic shop management system project report.pdf

Buying new cosmetic products is difficult. It can even be scary for those who have sensitive skin and are prone to skin trouble. The information needed to alleviate this problem is on the back of each product, but it's thought to interpret those ingredient lists unless you have a background in chemistry.

Instead of buying and hoping for the best, we can use data science to help us predict which products may be good fits for us. It includes various function programs to do the above mentioned tasks.

Data file handling has been effectively used in the program.

The automated cosmetic shop management system should deal with the automation of general workflow and administration process of the shop. The main processes of the system focus on customer's request where the system is able to search the most appropriate products and deliver it to the customers. It should help the employees to quickly identify the list of cosmetic product that have reached the minimum quantity and also keep a track of expired date for each cosmetic product. It should help the employees to find the rack number in which the product is placed.It is also Faster and more efficient way.

一比一原版(IIT毕业证)伊利诺伊理工大学毕业证成绩单专业办理

IIT毕业证原版定制【微信:176555708】【伊利诺伊理工大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Explore the innovative world of trenchless pipe repair with our comprehensive guide, "The Benefits and Techniques of Trenchless Pipe Repair." This document delves into the modern methods of repairing underground pipes without the need for extensive excavation, highlighting the numerous advantages and the latest techniques used in the industry.

Learn about the cost savings, reduced environmental impact, and minimal disruption associated with trenchless technology. Discover detailed explanations of popular techniques such as pipe bursting, cured-in-place pipe (CIPP) lining, and directional drilling. Understand how these methods can be applied to various types of infrastructure, from residential plumbing to large-scale municipal systems.

Ideal for homeowners, contractors, engineers, and anyone interested in modern plumbing solutions, this guide provides valuable insights into why trenchless pipe repair is becoming the preferred choice for pipe rehabilitation. Stay informed about the latest advancements and best practices in the field.

Final project report on grocery store management system..pdf

In today’s fast-changing business environment, it’s extremely important to be able to respond to client needs in the most effective and timely manner. If your customers wish to see your business online and have instant access to your products or services.

Online Grocery Store is an e-commerce website, which retails various grocery products. This project allows viewing various products available enables registered users to purchase desired products instantly using Paytm, UPI payment processor (Instant Pay) and also can place order by using Cash on Delivery (Pay Later) option. This project provides an easy access to Administrators and Managers to view orders placed using Pay Later and Instant Pay options.

In order to develop an e-commerce website, a number of Technologies must be studied and understood. These include multi-tiered architecture, server and client-side scripting techniques, implementation technologies, programming language (such as PHP, HTML, CSS, JavaScript) and MySQL relational databases. This is a project with the objective to develop a basic website where a consumer is provided with a shopping cart website and also to know about the technologies used to develop such a website.

This document will discuss each of the underlying technologies to create and implement an e- commerce website.

Immunizing Image Classifiers Against Localized Adversary Attacks

This paper addresses the vulnerability of deep learning models, particularly convolutional neural networks

(CNN)s, to adversarial attacks and presents a proactive training technique designed to counter them. We

introduce a novel volumization algorithm, which transforms 2D images into 3D volumetric representations.

When combined with 3D convolution and deep curriculum learning optimization (CLO), itsignificantly improves

the immunity of models against localized universal attacks by up to 40%. We evaluate our proposed approach

using contemporary CNN architectures and the modified Canadian Institute for Advanced Research (CIFAR-10

and CIFAR-100) and ImageNet Large Scale Visual Recognition Challenge (ILSVRC12) datasets, showcasing

accuracy improvements over previous techniques. The results indicate that the combination of the volumetric

input and curriculum learning holds significant promise for mitigating adversarial attacks without necessitating

adversary training.

Architectural Portfolio Sean Lockwood

This portfolio contains selected projects I completed during my undergraduate studies. 2018 - 2023

Recently uploaded (20)

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

Fundamentals of Electric Drives and its applications.pptx

Fundamentals of Electric Drives and its applications.pptx

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

CFD Simulation of By-pass Flow in a HRSG module by R&R Consult.pptx

CFD Simulation of By-pass Flow in a HRSG module by R&R Consult.pptx

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Cosmetic shop management system project report.pdf

Cosmetic shop management system project report.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Final project report on grocery store management system..pdf

Final project report on grocery store management system..pdf

Planning Of Procurement o different goods and services

Planning Of Procurement o different goods and services

Immunizing Image Classifiers Against Localized Adversary Attacks

Immunizing Image Classifiers Against Localized Adversary Attacks

Study on WMA using BFS

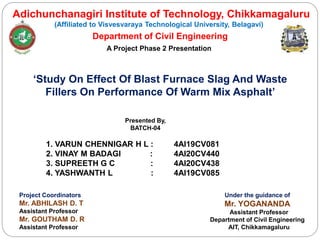

- 1. Adichunchanagiri Institute of Technology, Chikkamagaluru (Affiliated to Visvesvaraya Technological University, Belagavi) Department of Civil Engineering A Project Phase 2 Presentation ‘Study On Effect Of Blast Furnace Slag And Waste Fillers On Performance Of Warm Mix Asphalt’ Presented By, BATCH-04 1. VARUN CHENNIGAR H L : 4AI19CV081 2. VINAY M BADAGI : 4AI20CV440 3. SUPREETH G C : 4AI20CV438 4. YASHWANTH L : 4AI19CV085 Under the guidance of Mr. YOGANANDA Assistant Professor Department of Civil Engineering AIT, Chikkamagaluru Project Coordinators Mr. ABHILASH D. T Assistant Professor Mr. GOUTHAM D. R Assistant Professor

- 2. Contents 2 Introduction Literature Review Objectives of the Project Work Methodology Experimental program experimental investigation References

- 3. Abbreviations 3 HMA : Hot Mix Asphalt WMA : Warm Mix Asphalt CMA : Cold Mix Asphalt BFS : Blast Furnace Slag RHA : Rice Husk Ash BA : Bottom Ash WGP : Waste Glass Powder

- 4. Introduction 4 Fig. 1:Pavement Construction Methodologies

- 5. Contd… 5 Waste fillers used are: Potholes: Bottom Ash Waste Glass Powder Rice Husk Ash Potholes Pothole Patching BFS

- 6. Literature Review 6 1. J Wielinski et al, (2009) WMA is much like HMA, but it is produced at lower plant temperatures than conventional HMA. The objectives of these demonstrations were (a) to demonstrate that WMA with reclaimed asphalt pavement could be produced and placed at lower temperatures while yielding mix properties and field compaction similar to those of conventional HMA and (b) to construct field test sections so that WMA and HMA performance could be compared side by side. 2. FCG Martinho et al. (2018) This paper focuses on the comparison of the mechanical performance of three warm-mix asphalt (WMA) blends with recycled concrete aggregate (RCA) or electric arc furnace slag (EAFS) as substitutes of part of the aggregate . The evaluation was carried out in a laboratory by means of testing specimens taken from experimental pavement sections built in real production, laying and compaction circumstances 3. C Hettiarachchi et al. (2018) Use of reclaimed asphalt pavement (RAP) materials in warm mix asphalt (WMA) mixtures is getting popular around the world due to economic and environmental benefits.

- 7. Contd… 7 4. Jony, Al-Rubaie, & Jahad et al. (2011) , Considering the glass powder (GP) as filler, several researchers found that the use of recycled GP does not worsen mechanical and performance properties of asphalt mixtures. For instance, it is indicated that replacement of limestone filler by GP resulted in lower flow rate and higher stability 5. Ayman Ali et al, (2013) A study was conducted to evaluate the effect of temperature reduction, foaming water content, and aggregate moisture content on the performance of foamed WMA.Two asphalt binders (PG 70- 22 and PG 64-28), two aggregate types (limestone and crushed gravel), and two nominal maximum aggregate sizes (12.5 mm and 19.0 mm) were used in this study.The asphalt pavement analyzer test was utilized to evaluate the rutting resistance, and the indirect tensile strength and the Modified Lottman (AASHTO T 283) tests were utilized to evaluate the moisture sensitivity of the asphalt mixtures. 6. Choudry J et al. (2021) uses glass powder and glass-hydrated lime as alternative fillers in place of stone dust. It Resulted in reduction of cost of the pavement to 33-35% and 21% more economical and exhibited better laboratory performance. The use of this mix can also conserve 280 tons and 28 tons of conventional aggregate and binder.

- 8. Objectives of the Project Work 8 To conduct various preliminary laboratory tests on all materials as per standard specifications. To design and develop a Conventional Warm Mix Asphalt (WMA) and the Warm Mix Asphalt with Blast Furnace Slag replaced aggregates and waste materials replaced fillers as per standard design method in the laboratory and to conduct standard performance evaluation tests on the developed mixes. To compare the performance of both mixes and to recommend the suitable Warm Mix Asphalt mixture with Blast Furnace slag and fillers for the patching of pothole.

- 9. Methodology 9 The first and the foremost thing of the project is that procurement of material such as aggregate, Binder, Blast furnace Slag and waste materials as fillers. Preliminary laboratory test will be conducted as per relevant code specifications. Next, development of warm mix asphalt mixture will be conducted for the pothole gradation based on IRC: 116- 2014. The comparison between conventional WMA and WMA with Blast Furnace slag and waste materials will be made based on performance evaluation. At last, conclusions will be made for pothole patching with optimum strength based on detailed resist analysis.

- 10. Contd… 10 LITERATURE REVEW PROCUREMENT OF MATERIALS AGGRIGA TE WASTE MATERIAL S AS FILLERS PRELIMINARY LABORATORY TEST BFS BINDE R DEVELOPMENT OF WMA MIXTURE ANALYSIS OF RESULT PERFORMANCE EVALUATION TEST COMBINE D SPECIME N CONDUCTION AND RECOMMENDATION OF WMA MIX FOR POTHOLES COMPARSION OF PERFORMANCE OF BOTH THE MIXES WMA WITH BFS AND WASTE MATERIALS CONVENTIONAL WMA

- 11. Experimental Program: Table 1: Test on Aggregate used in Pavement Construction 11 Sl. No. Name of Test IS Code 1 Aggregate Impact test IS:2386-Part 4 2 Aggregate Abrasion test IS:2386-Part 4 3 Aggregate Crushing test IS:2386-Part 4 4 Shape test IS:2386-Part 1 5 Specific Gravity test IS:2386-Part 3 These test are also conducted on Blast Furnace Slag.

- 12. Sl. no Name of Test IS Code 1 Penetration test IS:1208-1978 2 Softening Point test IS:1208-1978 3 Ductility test IS:1208-1978 4 Viscosity test IS:1208-1978 5 Specific Gravity test IS:1208-1978 12 Test on Bitumen with there VG-30: Table 2: Test on Bitumen VG-30 Test on Bitumen Mix Design: Sl. No. Name of Test 1 Marshall Stability test Table 3: Test on HWM

- 13. 13 Experimental Investigation • Material testing Coarse Aggregates Sl no Test Value Standard value 1 Specific Gravity 2.77 2.5-3 2 Aggregate Crushing test 25.1% 30% 3 Aggregate Impact test 18.2% 30% 4 Aggregate Abrasion test 24.16% 30%

- 14. 14 Sieve Analysis: 0 10 20 30 40 50 60 70 80 1 10 100 % finer sieve size sieve analysis curve

- 15. 15 Experimental Investigation • Material testing Blast Furnace slag Sl no Test Value Standard value 1 Specific Gravity 2.08 2.5-3 2 Aggregate Crushing test 37.54% 30% 3 Aggregate Impact test 35.21% 30% 4 Aggregate Abrasion test 26.45% 30% 5 Shape test • Elongation • Flakiness 36.15% 10.05% 25%

- 16. 16 Sieve Analysis: 0 10 20 30 40 50 60 70 1 10 100 % finer Sive size sieve analysis curve

- 17. 17 Fillers Specific Gravity Sl no Fillers Value 1 Bottom Ash 2.58 2 Rice husk Ash 2.48 3 Waste Glass Powder 2.15

- 18. 18 Bitumen (VG-30) Sl No Test Value Standard Value 1 Specific Gravity test 0.98 0.98-1.02 2 Penetration test 66.44 mm 52-75mm 3 Flash & Fire Point 220c & 275c 220-300c 4 Ductility test 55 cm 45-60 cm 5 Softening Point test 49 c 35-75c

- 19. 19 Work to be Done • Casting of Specimens • Air Curing • Test on Specimen- Marshal Stability test

- 20. 20 Details of Specimen Sl No Coarse Aggregate (%) Blast Furnace Slag (%) No of Specimen 1 100 0 15 2 75 25 15 3 50 50 15 4 25 75 15 5 0 100 15 Proportions aggregate to be used: Sl no Stone dust (%) Rice husk ash(%) Waste glass powder(%) Bottom Ash(%) 1 0 33.33 33.33 33.33 2 25 25 25 25 3 50 16.67 16.67 16.67 4 75 8.33 8.33 8.33 5 100 0 0 0

- 21. 21 No of specimen to be casted Sl No Aggrega te in % Blast Furnace slag in % Bitumen in % Total 5 5.5 6 6.5 7 1 100 0 3 3 3 3 3 15 2 75 25 3 3 3 3 3 15 3 50 50 3 3 3 3 3 15 4 25 75 3 3 3 3 3 15 5 0 100 3 3 3 3 3 15

- 22. 22 Comparative Study: Based on Marshal Stability Test, Stability Values will be compared and Optimum Strength Percentage mix would be recommended.

- 23. References 23 (1) Viktors Haritonovs 2 and Martins Zaumanis 3.; Moreno, F.Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. (2) Umair Hasana,c*, Andrew Whytea, Hamad Al Jassmib,c. State of the art review on mix design and mechanical properties of warm mix asphalt. Road Mater. Pavement Des. 2018, 20, 1501–1524. (3 Dharsan GM1, Gokul S2 and M.Praba3 Performance evaluation of warm mix asphalt containing reclaimed asphalt mixtures. Int. J. Pavement Eng. 2016, 18, 981–989. (4) Hayder Kamil Shanbara 2 and Tariq Al-Mansoori 3 S.A. Laboratory evaluation of rutting and moisture damage resistance of glass fiber modified warm mix asphalt incorporating high rap proportion. Constr. Build. Mater. 2017, 134, 626–640. (5) Marco Pasetto1 and Nicola Baldo2. Long-Term Field Performance of Warm Mix Asphalt Technologies; The National Academies Press: Washington, DC, USA, 2017

- 24. Contd… 24 (6) J Wielinski et al, (2009)– “fatigue and self-healing characterizes of asphalt composites containing rock asphalts”. ELSEVIER (7) C Hettiarachchi et al. (2018), A. Cancer incidence among male Norwegian asphalt workers. Am. J. Ind. Med. 2003, 43, 88–95. (8) Miss. Gauri et al (2017).. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. (9) Erkut Yalcin et al (2018). Performance evaluation of warm mix asphalt containing reclaimed asphalt mixtures. Int. J. Pavement Eng. 2016, 18, 981–989.

- 25. 25