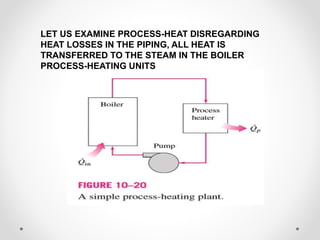

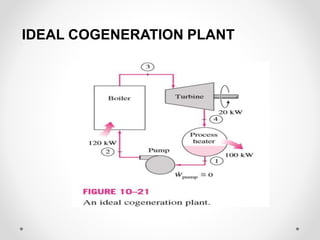

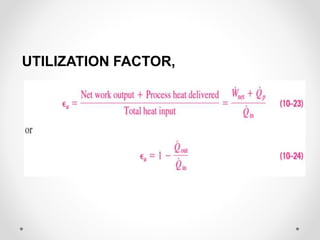

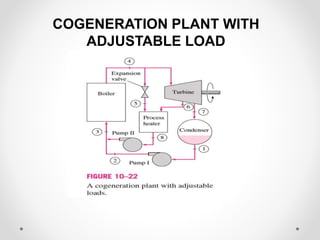

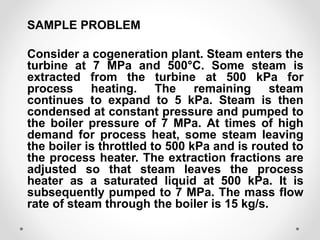

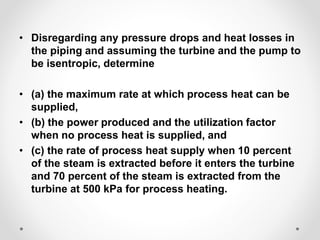

This document discusses cogeneration, which involves using a power plant to produce both electricity and useful thermal energy. Industries that rely heavily on process heat could benefit from cogeneration. An ideal cogeneration plant produces power and transfers remaining heat for industrial processes without waste. Sample calculations are provided for a cogeneration plant with adjustable steam extraction for power production and process heating.