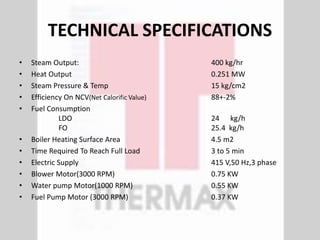

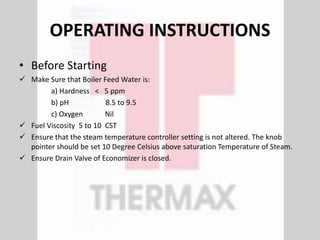

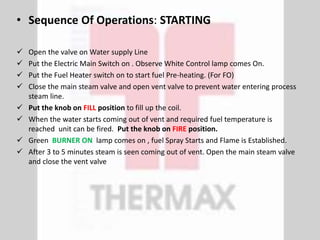

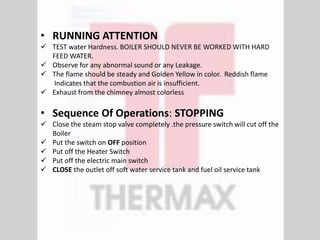

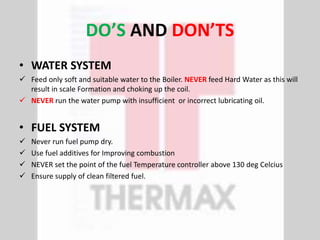

This document provides technical specifications and operating instructions for the Revomax RXA-04 boiler. The boiler can produce 400 kg/hr of steam at 15 kg/cm2 pressure and temperature. It has an efficiency of 88% and uses light diesel oil or furnace oil as fuel. Instructions are provided for starting up the boiler, monitoring it while running, and shutting it down safely. Key requirements outlined include using only soft feed water, maintaining proper fuel viscosity and temperature settings, and following safety precautions.