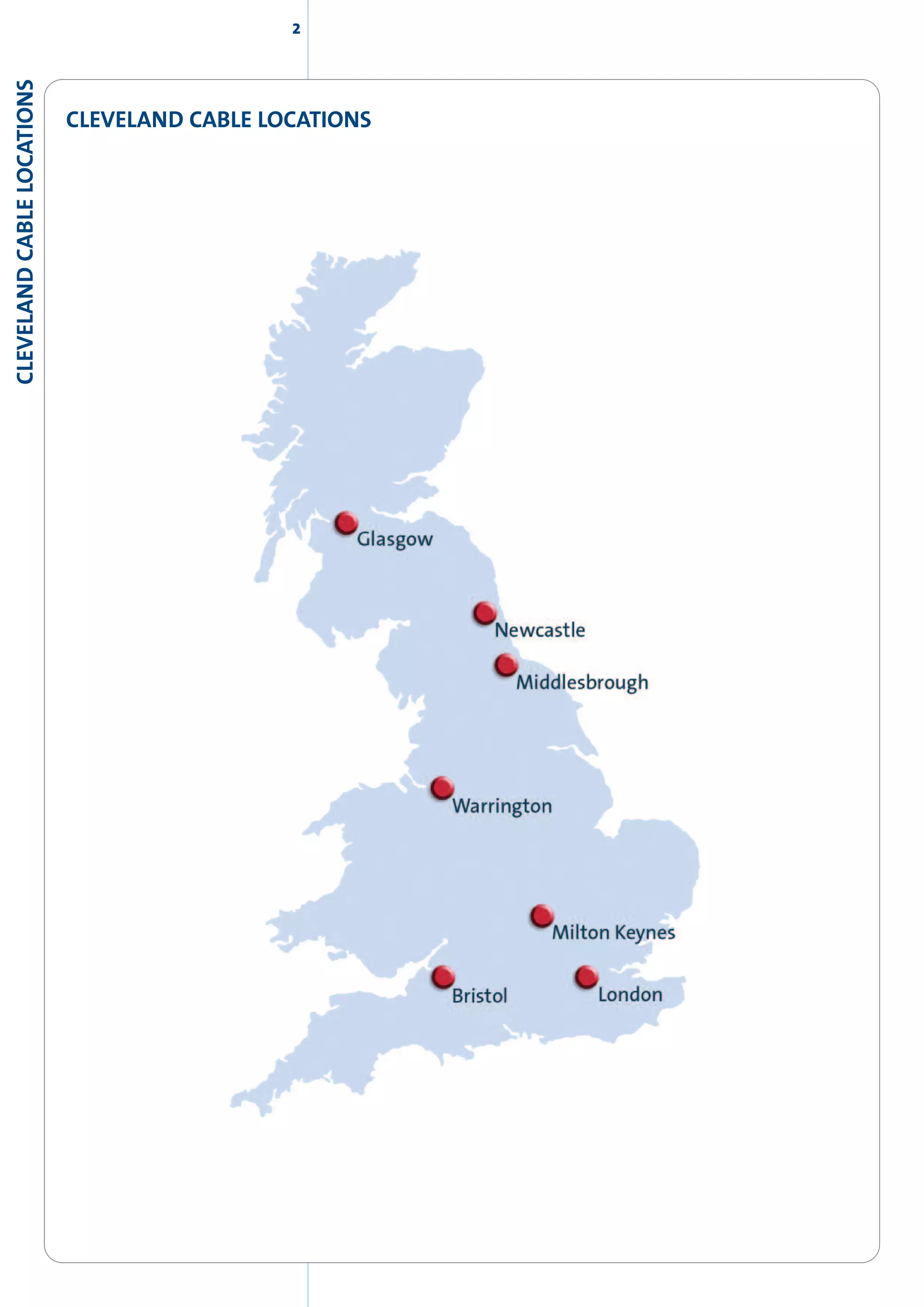

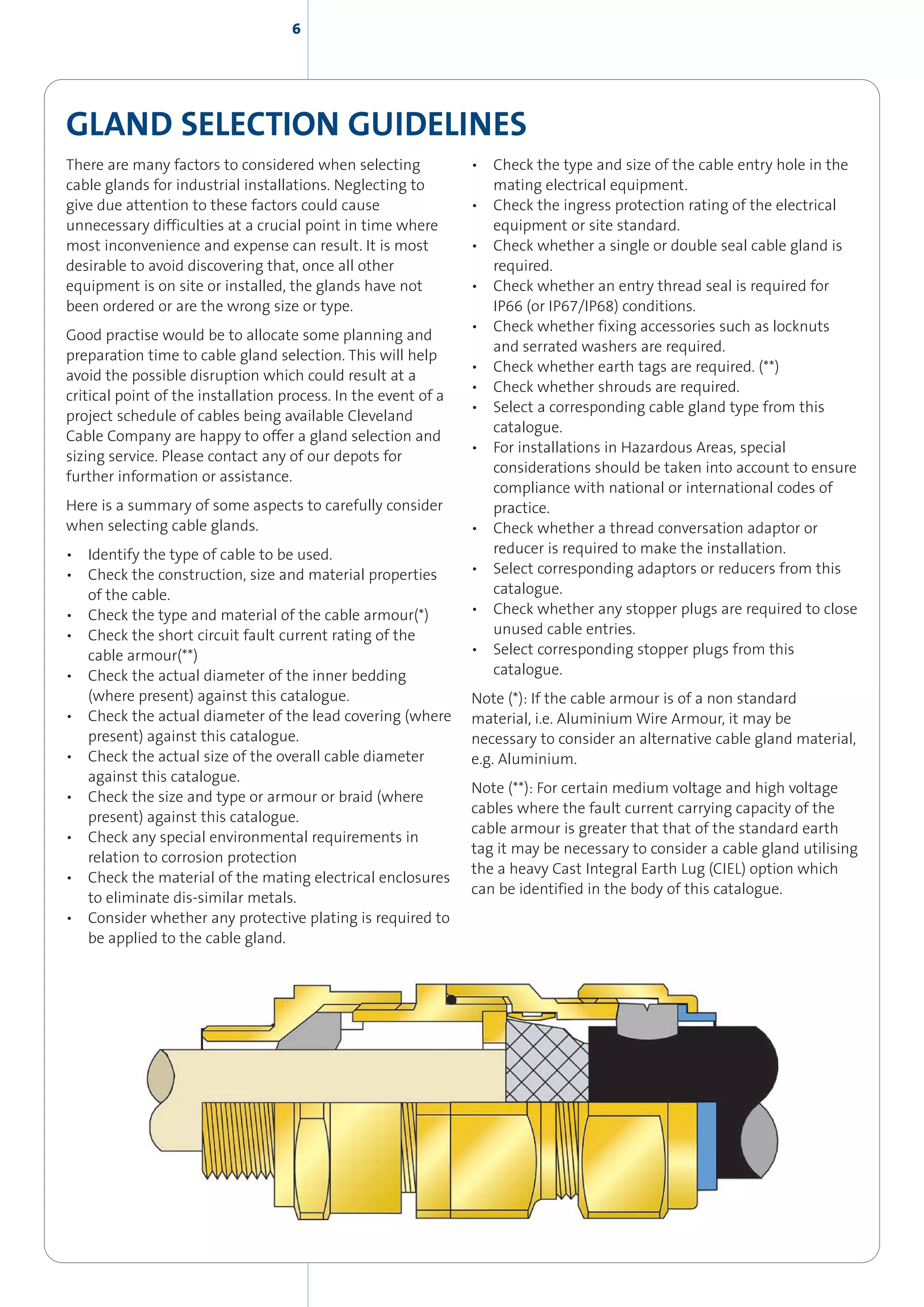

The document is a comprehensive catalog from Cleveland Cable Company detailing their extensive range of electrical cables and accessories available for immediate delivery. It includes guidance on selecting appropriate cable glands and highlights their commitment to providing high-quality service through ongoing investment in technology and equipment. The company operates multiple depots across the UK and offers efficient export services worldwide.