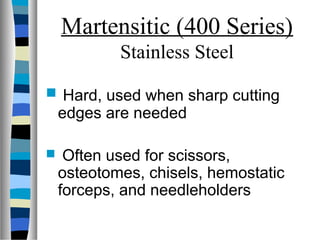

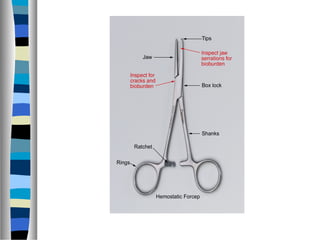

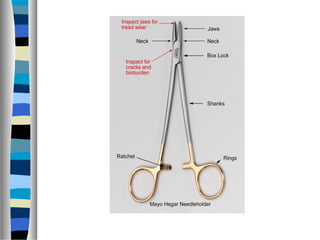

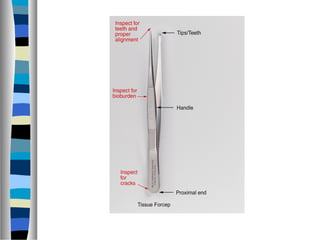

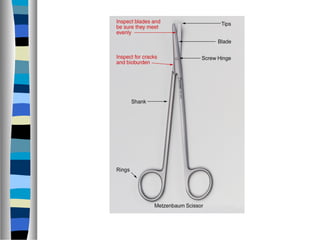

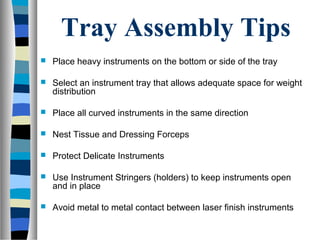

This document discusses the manufacturing, inspection, identification, and care of surgical instruments. It begins by outlining the objectives of reviewing instrument manufacturing processes and categories. It then describes the manufacturing steps including forging, grinding, heat treating, and passivation. It emphasizes the importance of Central Service Technicians and outlines proper procedures for instrument inspection, identification, lubrication, and tray assembly to maximize instrument lifespan.