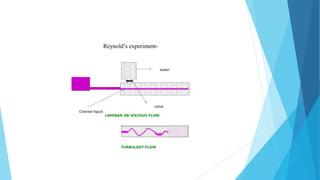

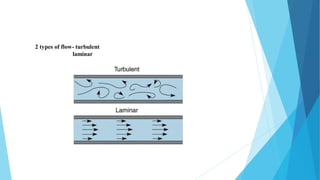

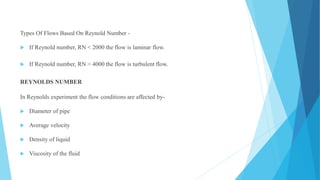

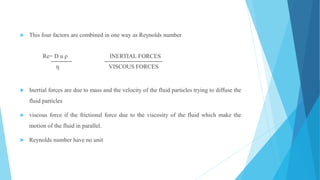

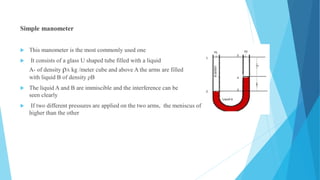

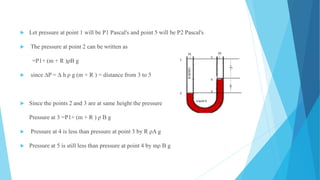

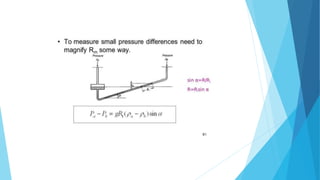

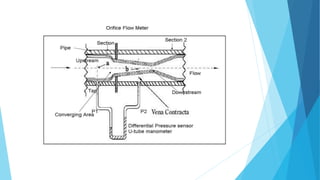

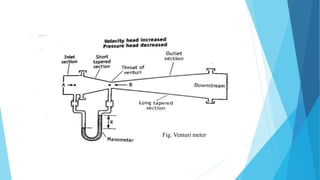

This document provides an overview of several devices used to measure fluid flow, including Bernoulli's theorem which is important to their functioning. It describes Reynolds' experiment which demonstrated laminar and turbulent flow. Bernoulli's theorem states that the total energy per unit mass of a fluid is constant. Several flow measurement devices are then explained, including orifice meters, venturi meters, and manometers which can be used to measure pressure differences involved. Orifice meters and venturi meters both use Bernoulli's theorem and measure the pressure drop caused by an increase in fluid velocity through a constriction to determine flow rate.