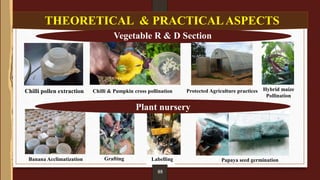

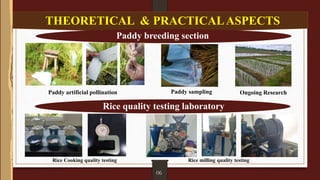

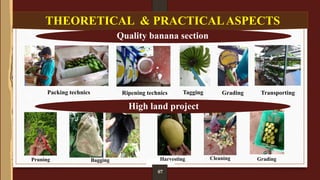

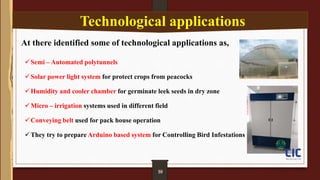

The document outlines the training program at CIC's Pelwehera farm, detailing the company's history, various agricultural divisions, and training components including both theoretical and practical skills. It emphasizes achievements in research and quality management practices related to crops like Cavendish banana and rice. The training also incorporates advanced technological applications aimed at enhancing agricultural productivity and farmer incomes.