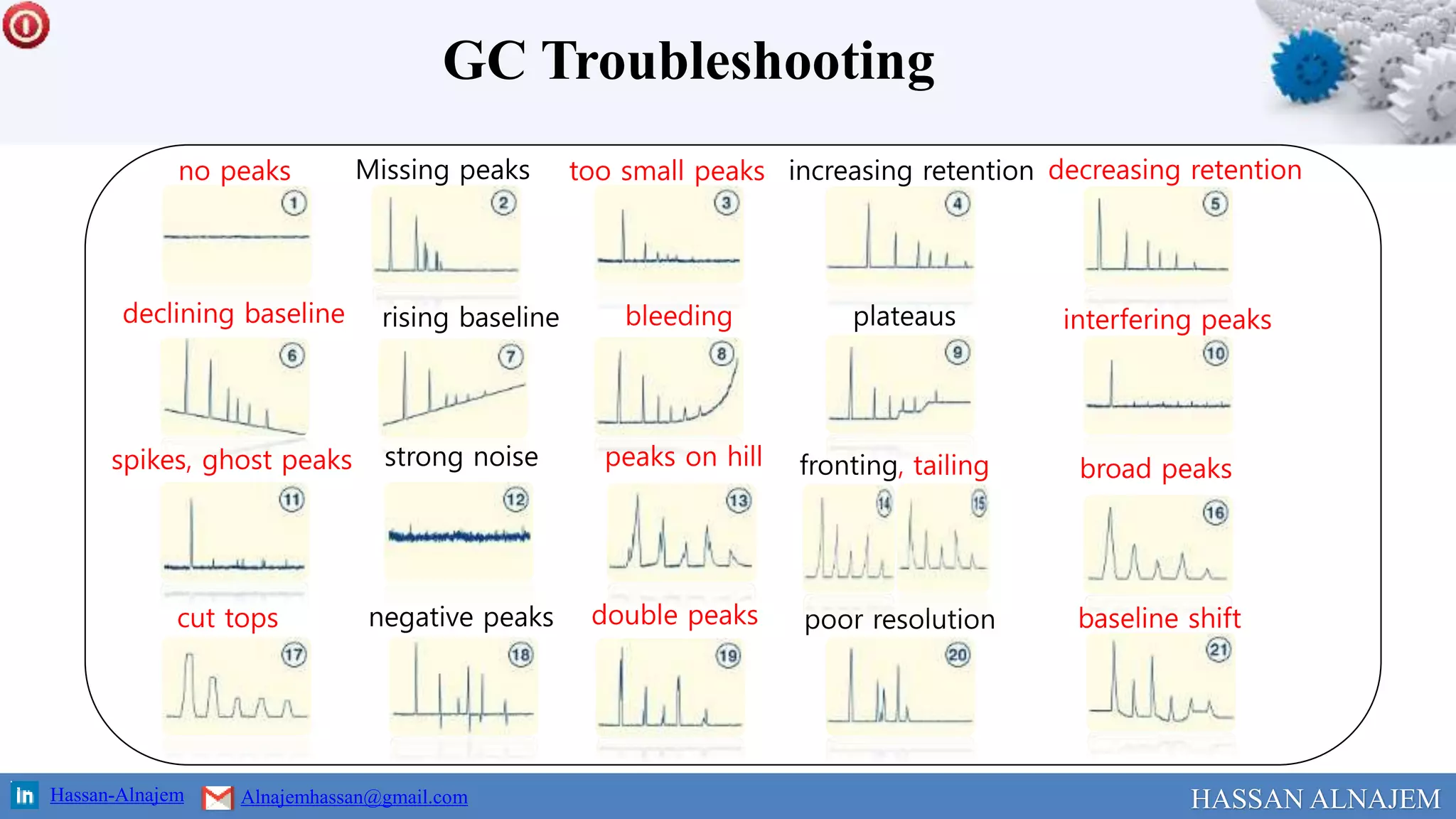

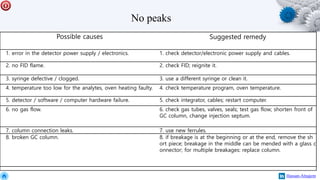

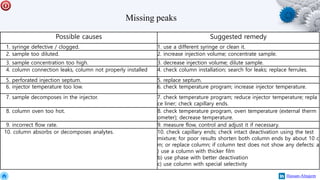

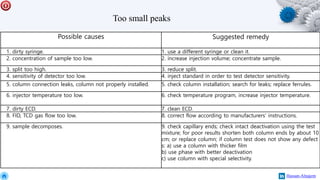

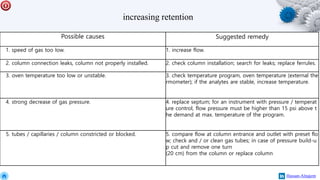

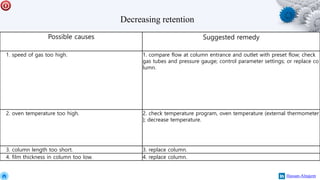

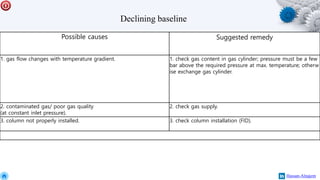

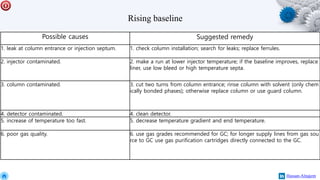

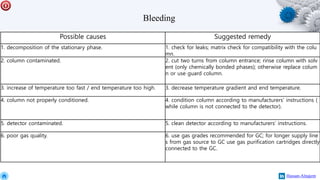

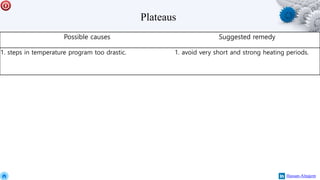

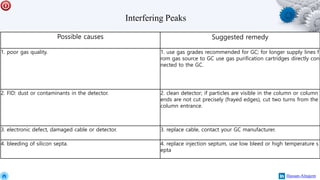

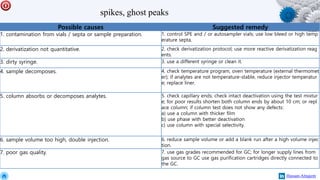

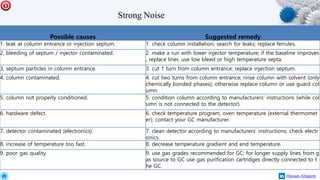

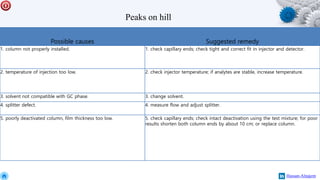

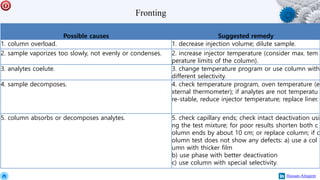

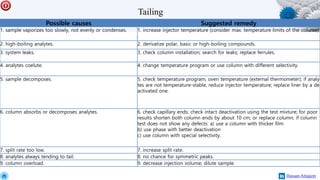

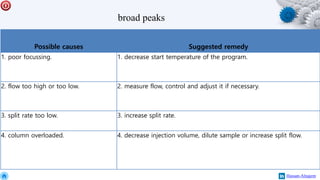

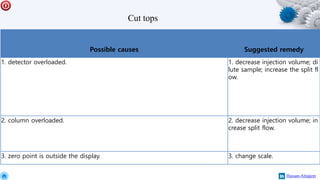

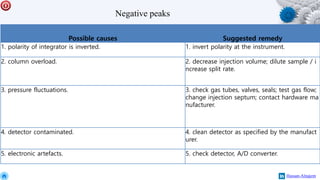

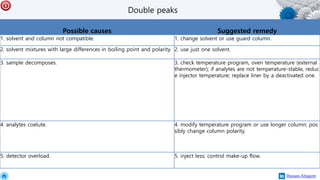

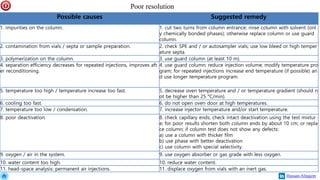

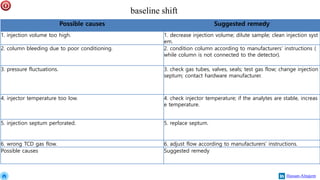

This document provides possible causes and suggested remedies for common gas chromatography (GC) troubleshooting issues. Some key issues addressed include no peaks, missing peaks, too small peaks, increasing or decreasing retention times, declining or rising baselines, interfering peaks, spikes, ghost peaks, broad peaks, fronting, tailing, cut tops, negative peaks, and double peaks. Suggested remedies include checking detector/electronics, gas flow, column installation, temperature programming, sample concentration, and column condition. The document is authored by Hassan Alnajem and provides troubleshooting guidance for resolving a variety of common GC performance problems.