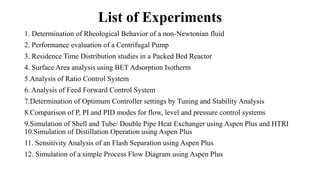

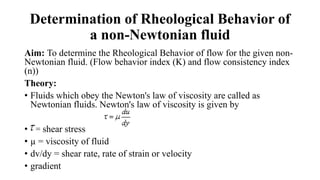

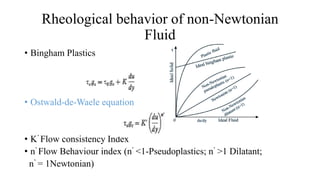

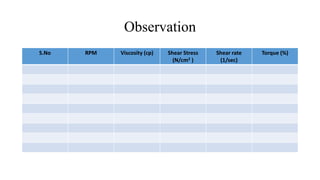

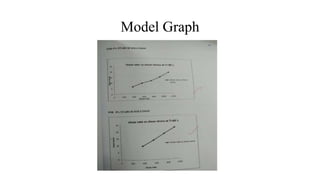

The document provides information about an upcoming laboratory experiment to determine the rheological behavior of a non-Newtonian fluid. It includes a list of 12 total experiments in chemical engineering laboratory 1. The specific experiment is aimed to determine the flow behavior index and flow consistency index of a non-Newtonian fluid by measuring viscosity, shear stress, and shear rate values. Key aspects of Newtonian and non-Newtonian fluid behavior are defined, and common types and examples of non-Newtonian fluids are described.