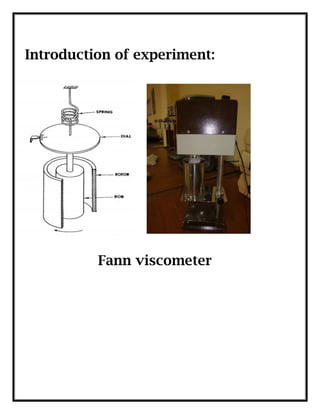

The document outlines an experiment conducted at Koya University to measure the plastic viscosity and yield point of drilling mud, which are critical for its flow behavior during drilling operations. The experiment details the procedure, theoretical background, and calculations necessary for evaluating the mud's properties, emphasizing the importance of viscosity in maintaining the suspension of drill cuttings. Additionally, it discusses potential sources of error related to temperature and equipment calibration, alongside references for further reading on fluid dynamics.