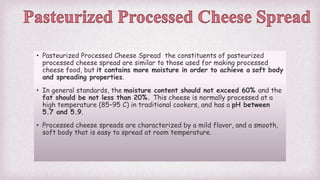

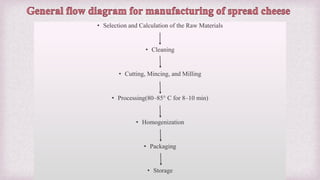

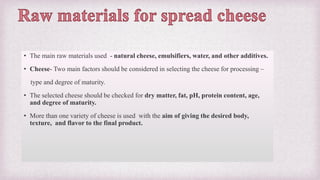

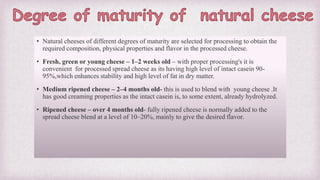

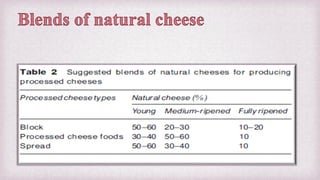

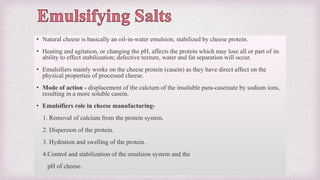

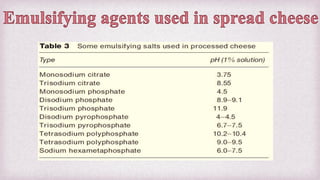

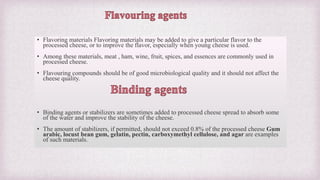

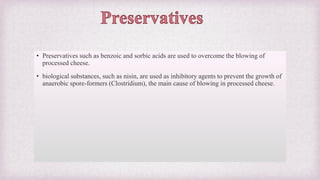

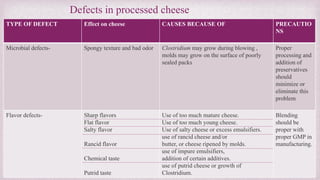

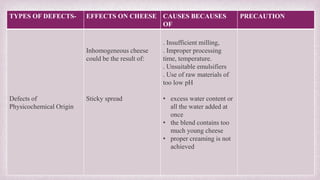

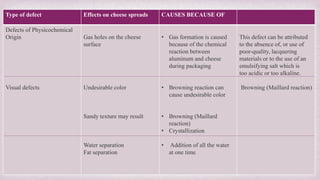

Processed cheese is made by blending natural cheeses and further processing them with emulsifying salts. There are two main types - pasteurized processed cheese and pasteurized processed cheese spread. Processed cheese spreads contain over 60% moisture and are characterized by their mild flavor and soft, spreadable texture. The production process involves selecting and blending various natural cheeses, adding emulsifying salts, water, and other optional ingredients. The blended cheese is then processed, homogenized, packaged, and stored. Processed cheese provides nutrients while having improved utilization of proteins compared to natural cheeses.