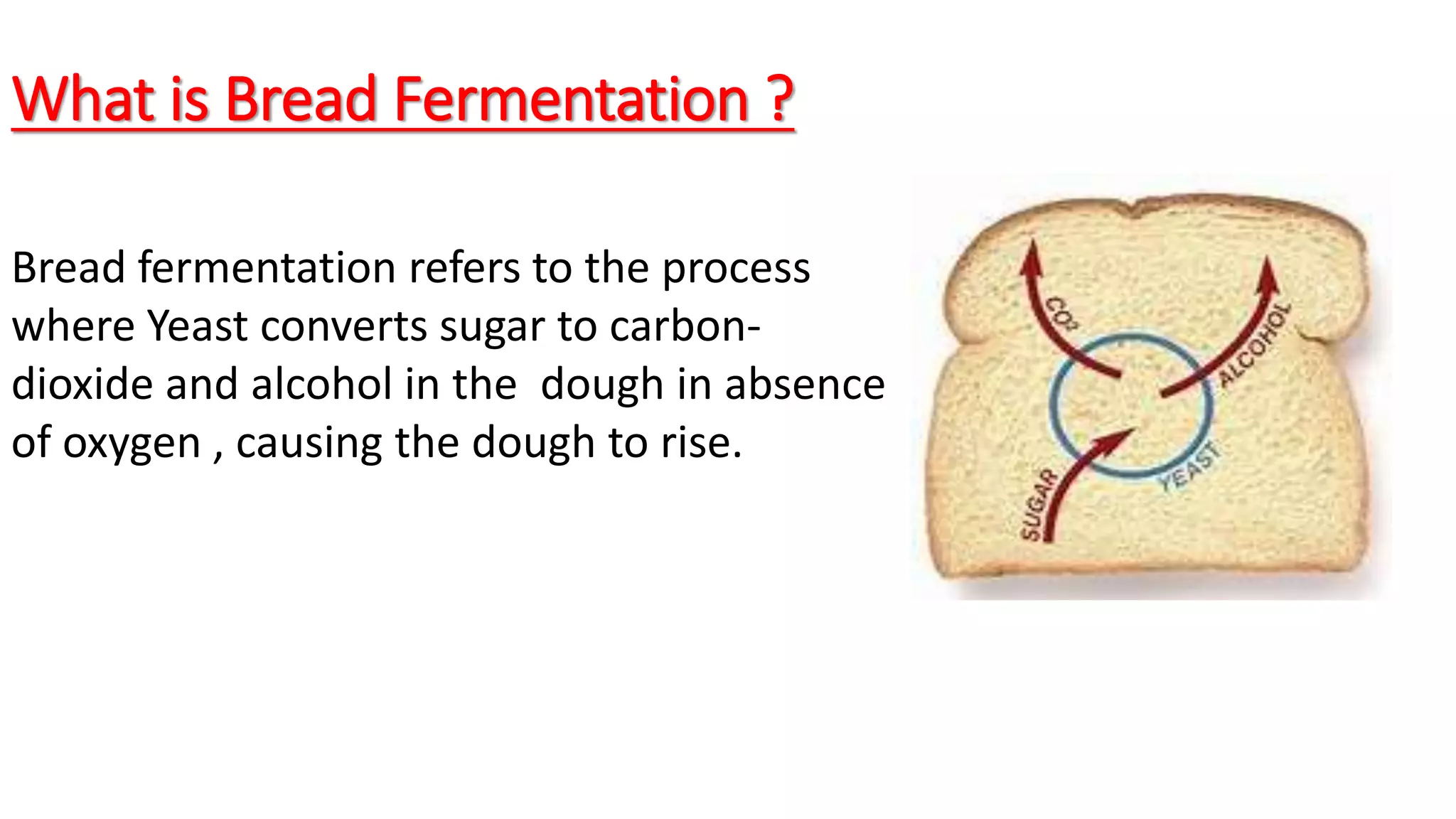

This document summarizes the process of bread production. It begins by describing bread fermentation, where yeast converts sugars to carbon dioxide and alcohol, causing the dough to rise. The history of bread making and common types of bread are then outlined. The document proceeds to discuss key aspects of the bread making process including ingredients, flour types, yeast varieties, mixing steps, fermentation, shaping, proofing, baking and cooling. Common bread formulations and properties of bakers' yeast are also summarized.