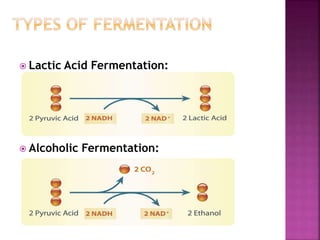

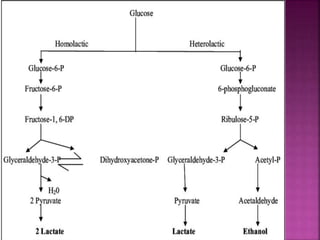

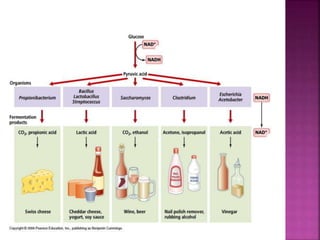

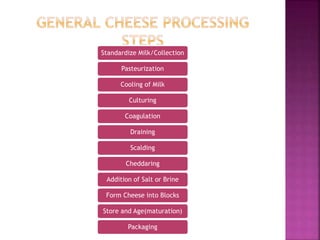

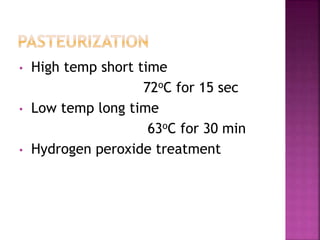

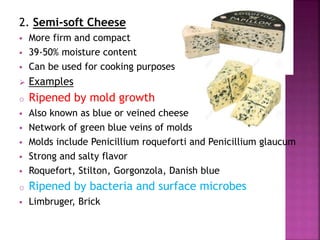

This document discusses fermentation in food processing and focuses on cheese production. It provides an introduction and history of cheese making. It describes the key types of fermentation used in cheese production and lists the microbes associated with cheese fermentation. The general cheese processing steps are outlined including standardization, pasteurization, culturing, coagulation, draining, pressing, aging, and packaging. Finally, it lists and describes common cheese types and their characteristics as well as the advantages and disadvantages of cheese consumption.