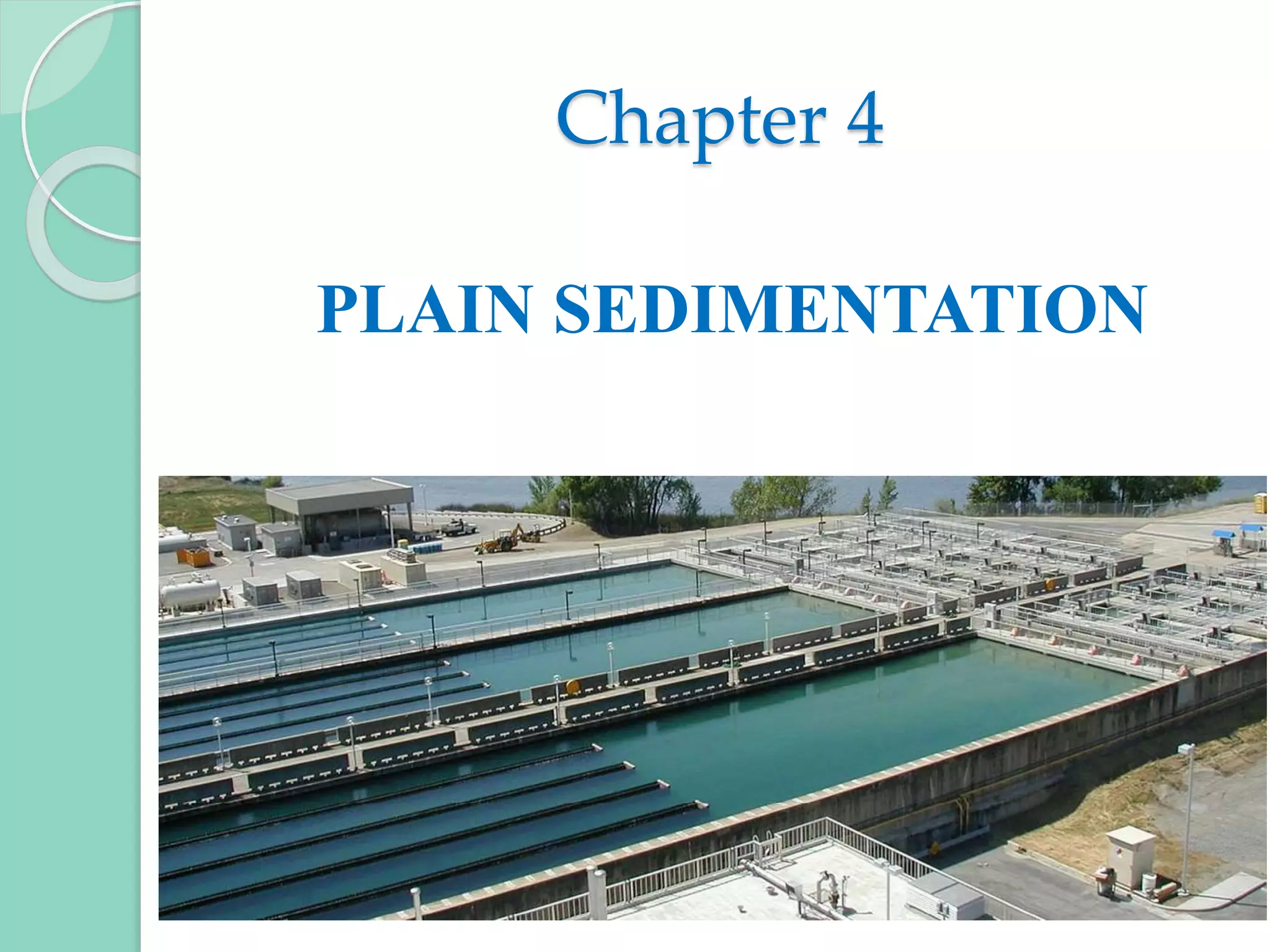

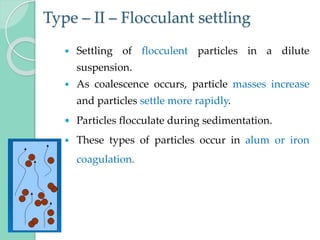

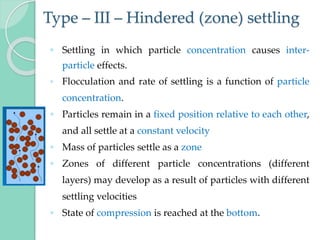

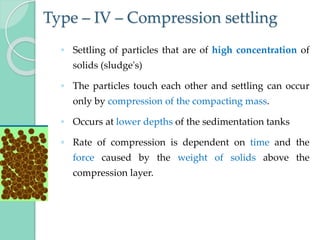

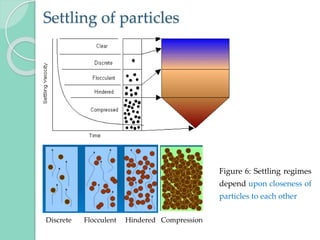

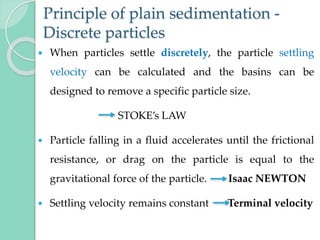

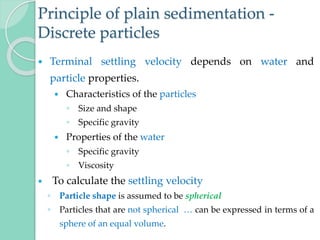

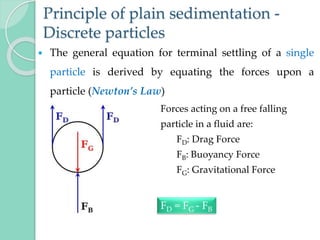

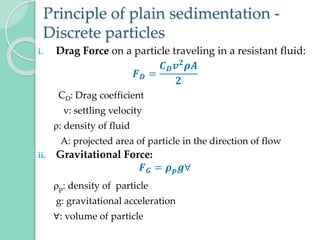

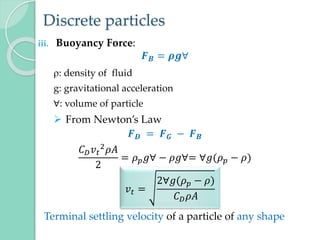

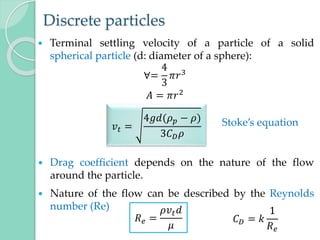

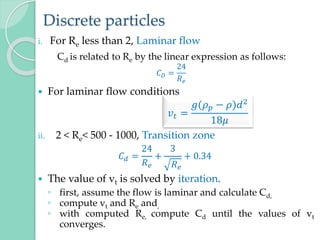

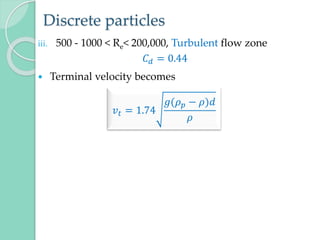

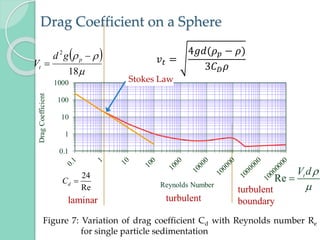

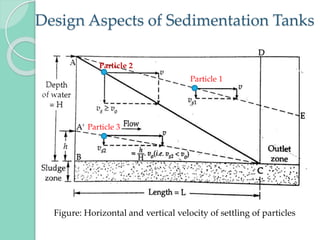

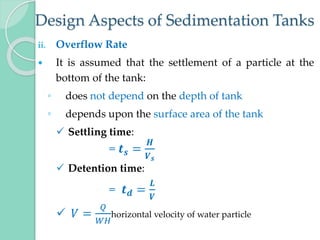

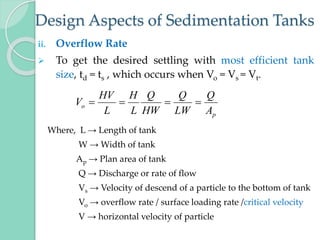

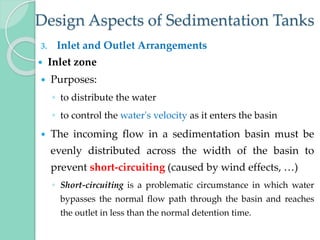

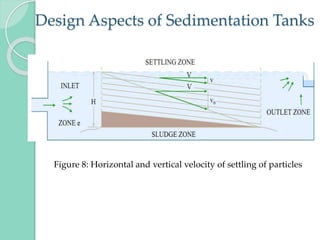

Plain sedimentation involves removing suspended solids from water through gravitational settling without the addition of chemicals. There are four types of particle settling regimes: discrete particle settling, flocculant settling, hindered settling, and compression settling. Discrete particle settling involves individual particles settling according to their size, shape, density and Stokes' Law. The design of sedimentation tanks considers factors such as flow velocity, tank capacity, inlet and outlet arrangements, and settling and sludge zones to facilitate effective particle removal.