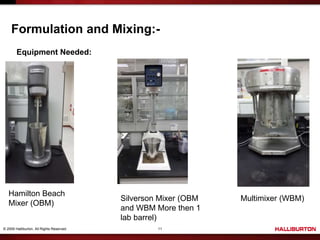

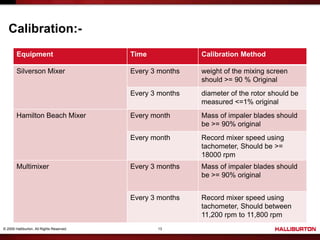

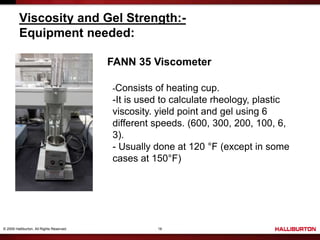

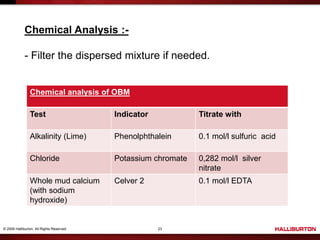

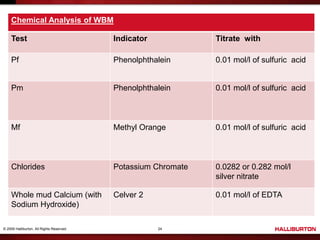

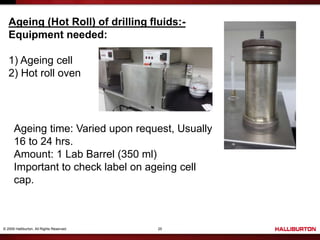

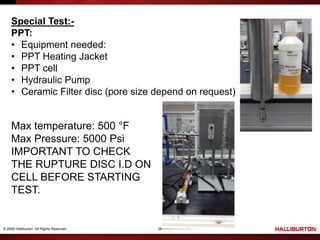

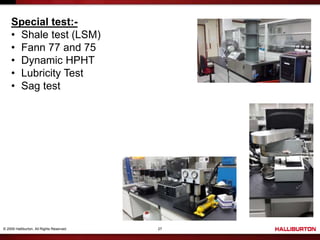

The document discusses drilling fluids used in oil and gas extraction. It describes the main types as oil-based mud and water-based mud. The key chemicals used are listed, along with their purposes, such as viscosifiers to remove cuttings and weighting agents to control pressure. The processes for formulating, mixing, testing properties like density and viscosity, and analyzing the chemical composition of drilling fluids are outlined. Specialized tests for conditions like high pressure and temperature are also addressed. The goal is to select the appropriate drilling fluid and ensure it meets specifications through testing and analysis.