Critical First Well Process: High Temperature Wells in Gulf of Thailand Block I – December 2013

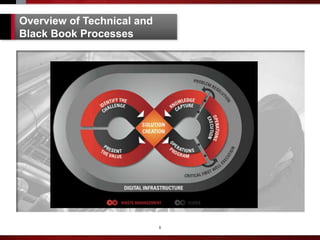

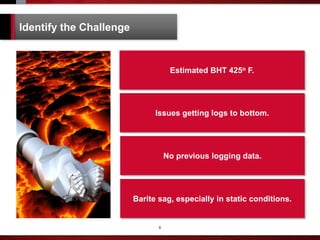

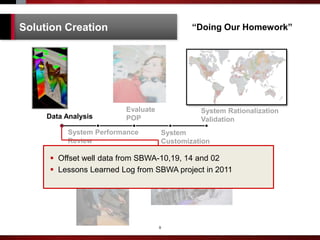

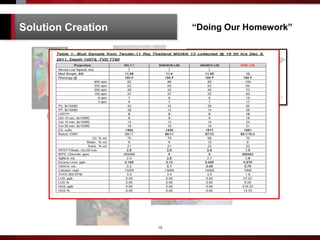

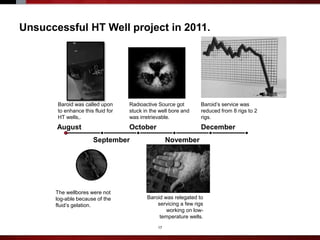

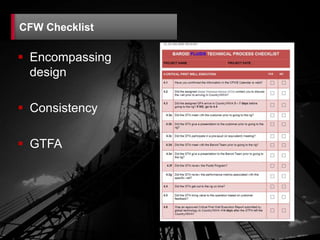

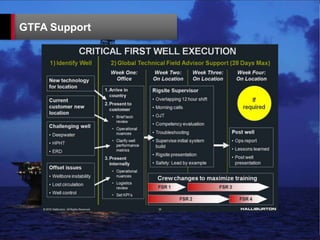

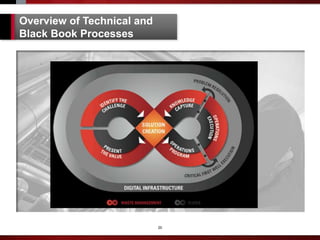

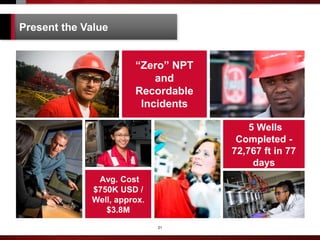

This document summarizes Halliburton's process for a critical first well involving high temperature wells drilled for Chevron Thailand Exploration in the Gulf of Thailand. It describes how Halliburton analyzed previous issues with high temperature wells, tested new drilling fluid formulations in multiple laboratories, and customized a solution to deliver successful drilling of five high temperature wells, with zero non-productive time or recordable incidents, finishing 77 days ahead of schedule. The critical first well process and checklist helped ensure customer focus, operational excellence, and fulfillment of commitments to Chevron.