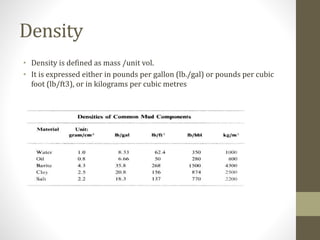

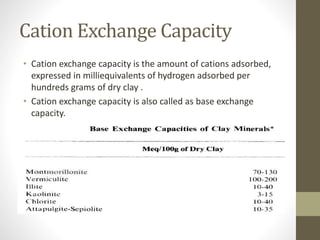

The document discusses various properties of drilling fluids including density, cation exchange capacity, filtration properties, pH, rheology, alkalinity, lubricity, and corrosivity. It defines these key terms and describes methods for measuring properties such as cation exchange capacity, pH, rheology, and corrosivity. Controlling properties like pH and alkalinity is important for drilling fluid performance and stability.

![pH

The pH is a measure of the hydrogen ion concentration, H+

pH= -log [H+]

The pH is usually measured with color-coded paper or with a

pH meter

Caustic soda (NaOH) and potassium hydroxide (KOH) are the

two chemicals commonly used in a water-based mud to

control pH value.

The optimum control of the mud systems is based on pH ,as is

the detection and treatment of the contaminations.

A mud made by Bentonite and Fresh water will have pH

between 8 and 9.

Contamination by cement will raise the pH to 10 and 11.](https://image.slidesharecdn.com/propertiesofdrillingfluids-200302173354/85/Properties-of-drilling-fluids-7-320.jpg)

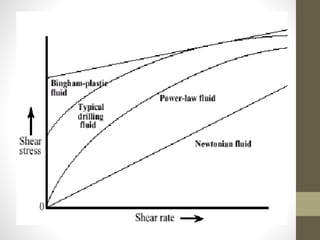

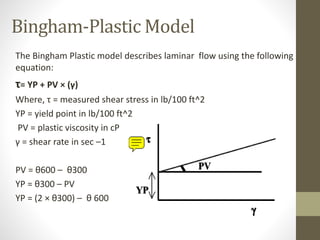

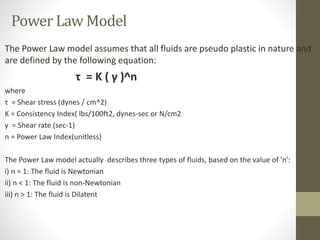

![A mathematical fluid model describes the flow

behavior of a fluid by expressing a mathematical

relationship between shear rate and shear stress.

The three rheological models that are currently in

use are:

Bingham Plastic model.

Power Law model.

Herschel-Bulkley (yield-power law [YPL]) model.

Flow models](https://image.slidesharecdn.com/propertiesofdrillingfluids-200302173354/85/Properties-of-drilling-fluids-13-320.jpg)

![The Herschel-Bulkley (yield- power law [YPL]) model describes the rheological

behavior of drilling muds more accurately than any other model using the following

equation:

τ = τ o + K × ( γ )^n

where

τ = measured shear stress in lb/100 ft^2

τo= fluid's yield stress (shear stre ss at zero shear rate) in lb/100 ft^2

K = fluid's consistency index in cP or lb/100 ft sec^2

n = fluid's flow index

γ= shear rate in sec-1

The YPL model reduces to the Bingham Plastic model when n = 1 and it reduces to the

Power Law model when τ o = 0.

Herschel-Bulkley](https://image.slidesharecdn.com/propertiesofdrillingfluids-200302173354/85/Properties-of-drilling-fluids-17-320.jpg)