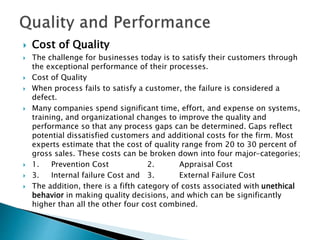

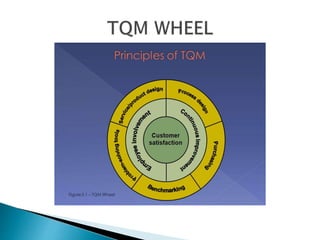

This document discusses the concept of quality costs in operations management. It defines four main categories of quality costs: prevention costs, appraisal costs, internal failure costs, and external failure costs. Prevention costs aim to prevent defects, appraisal costs assess process performance, and failure costs stem from defects. Total quality management focuses on customer satisfaction, employee involvement, and continuous process improvement to reduce quality costs.