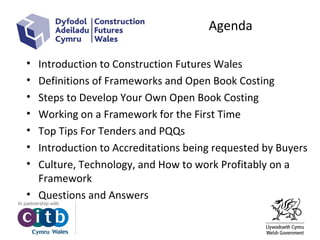

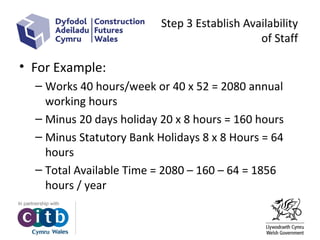

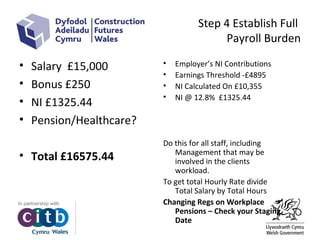

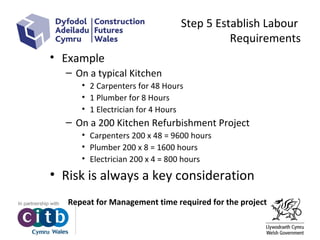

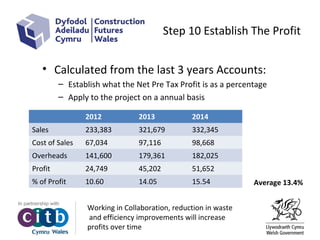

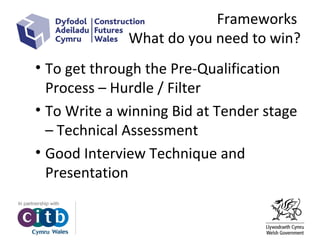

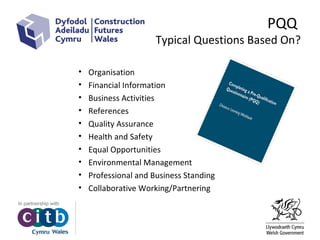

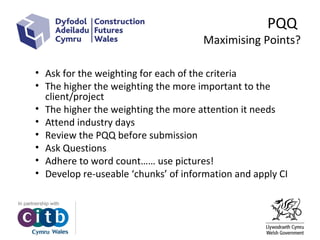

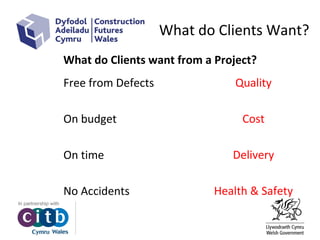

The document provides an overview of open book costing for construction projects and frameworks. It outlines 10 steps to develop an open book cost model including establishing workload, labor costs, material costs, plant/tools requirements, risk costs, overhead costs, and profit margin. The document also discusses qualifications needed to win frameworks like trade certifications and accreditations. It emphasizes the importance of collaboration, continuous improvement, and focusing on client needs to work profitably on frameworks.