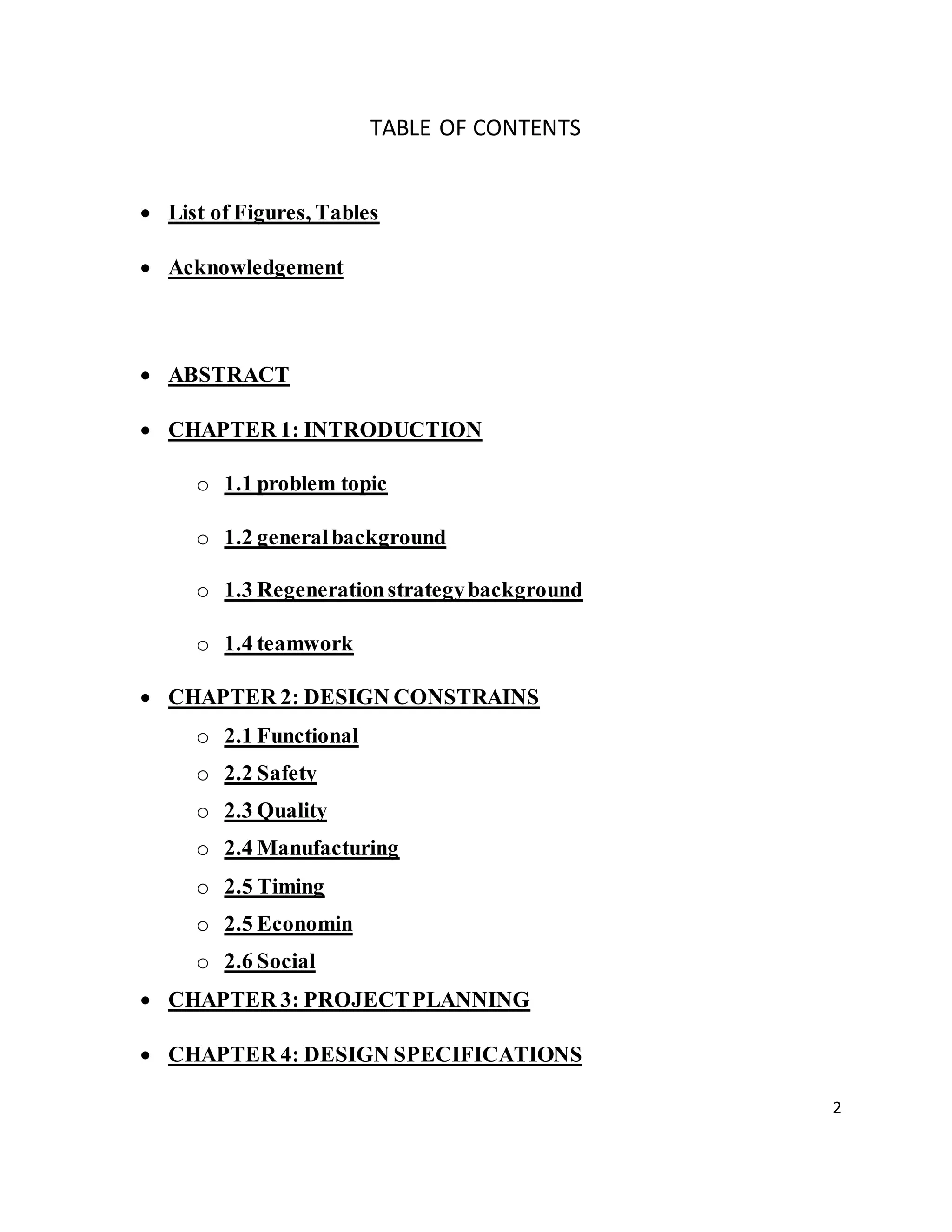

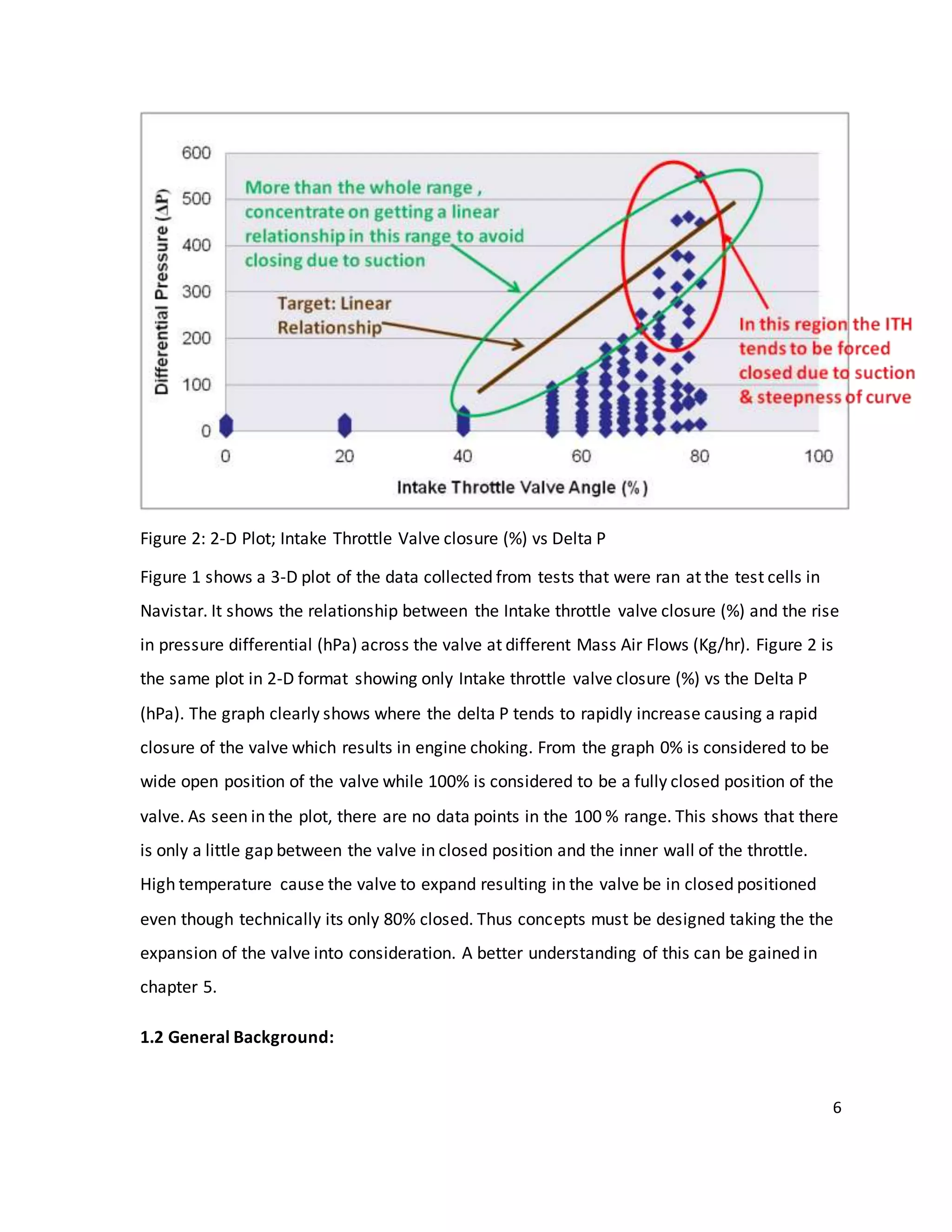

This document outlines the design of an intake throttle valve for a Navistar engine. It discusses the current issues with rapid closure of the throttle valve due to increasing pressure differential. Three concepts are proposed to address this - an orifice plate valve with a hole, an oval shaped valve, and a reduced diameter valve. Calculations of fluid flow and pressure differential would be used to select the best concept to prevent forced closure while meeting performance targets. Testing of a prototype part would then validate the chosen design.

![7

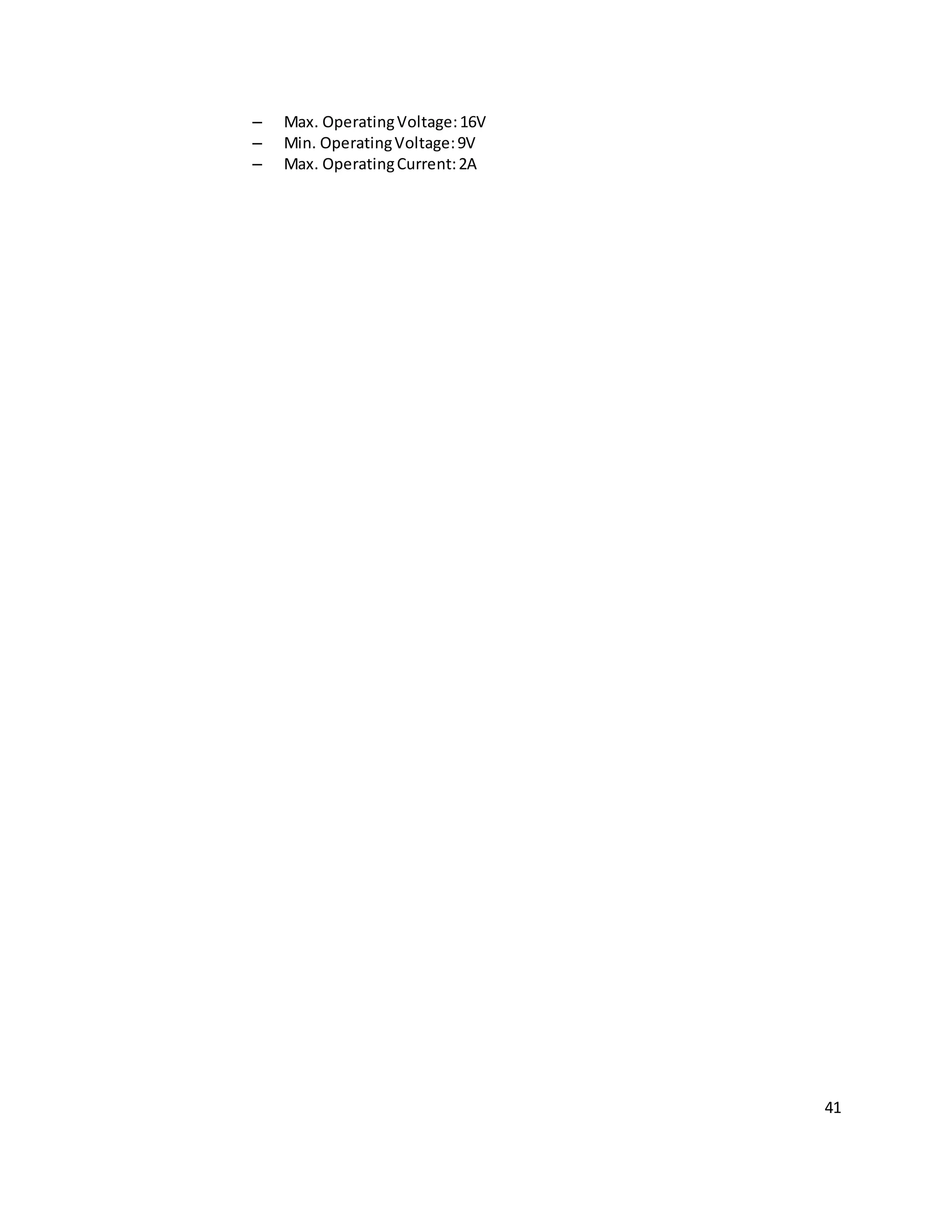

This project is assigned by the Aftertreatment department at Navistar. The

Aftertreatment department at Navistar deals with trying to achieve high Catalyst Inlet

temperatures in order to meet the EPA requirements. The target exhaust out temperatures

are tried to achieve by playing around with the Injection timings, EGR valve technology,

using the Intake Throttle and a Turbocharger. The target exhaust temperature going into

the Diesel Oxidation Catalyst is 275ºC - 300ºC, where as the target exhaust temperature

going into the Diesel Particulate Filter is 540ºC - 600ºC. The Target Diesel Oxidation

Temperature is needed to oxidize Carbon Monoxide (CO), Hydrocarbons (HC) and organic

fraction of diesel particulates (SOF). The Oxidation takes place as follows:

HC + O2 = CO2 + H2O ……. (I)

CO + 1/2O2 = CO2……….. (II)

2SO2 + O2 = 2SO3……… (III a)

SO3 + H20 = H2SO4……. (III b)

The target temperature going into the Diesel Particulate Filter is required for oxidation of

NOx. To read about the effects of catalysts on NOx refer Appendix [ ].

1.3 Regeneration Strategy Background:

Some of the strategies used by the companies to achieve target Exhaust out temperature for

regeneration are as follows:

1. Post Injection

Entirely new functions are performed by injection systems in engines with integrated

emission aftertreatment systems of Diesel Particulate Filters. These devices require

regeneration to burn all the soot which is provided by high temperatures or by rich

exhaust gas of rich HC content. These are achieved by late fuel injection which is also

called post injection. Thus Post injection provides a certain amount of high exhaust](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-7-2048.jpg)

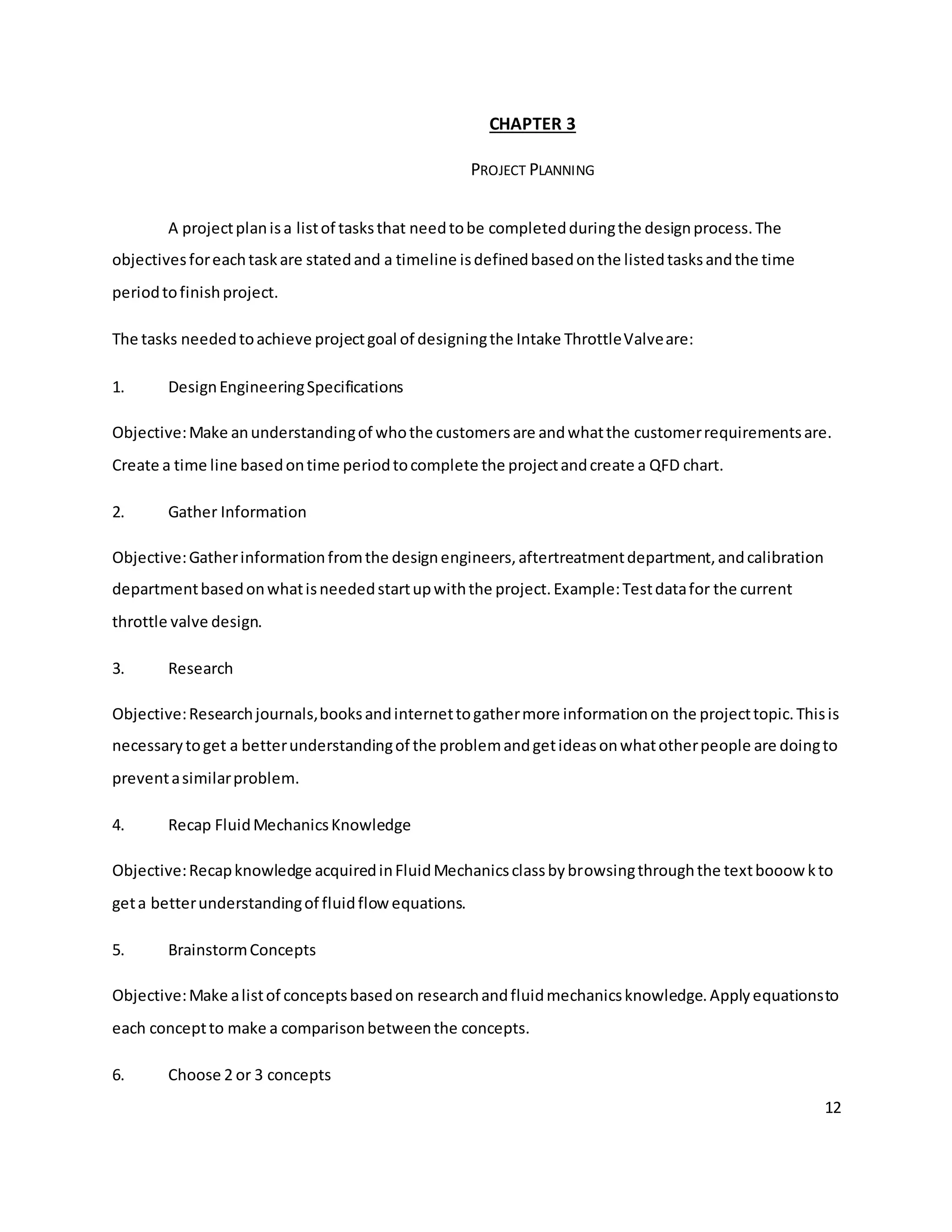

![16

CHAPTER 5

CONCEPT GENERATION

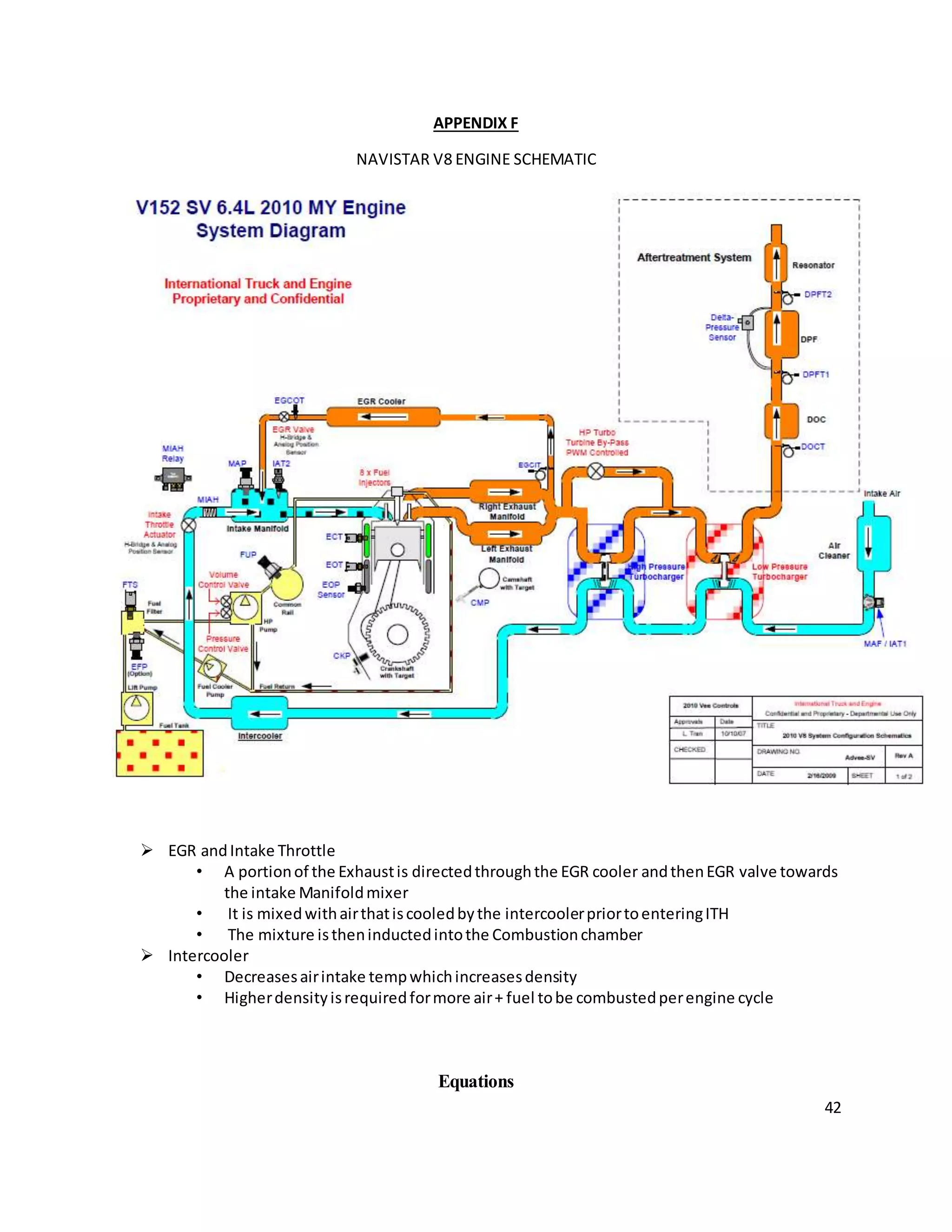

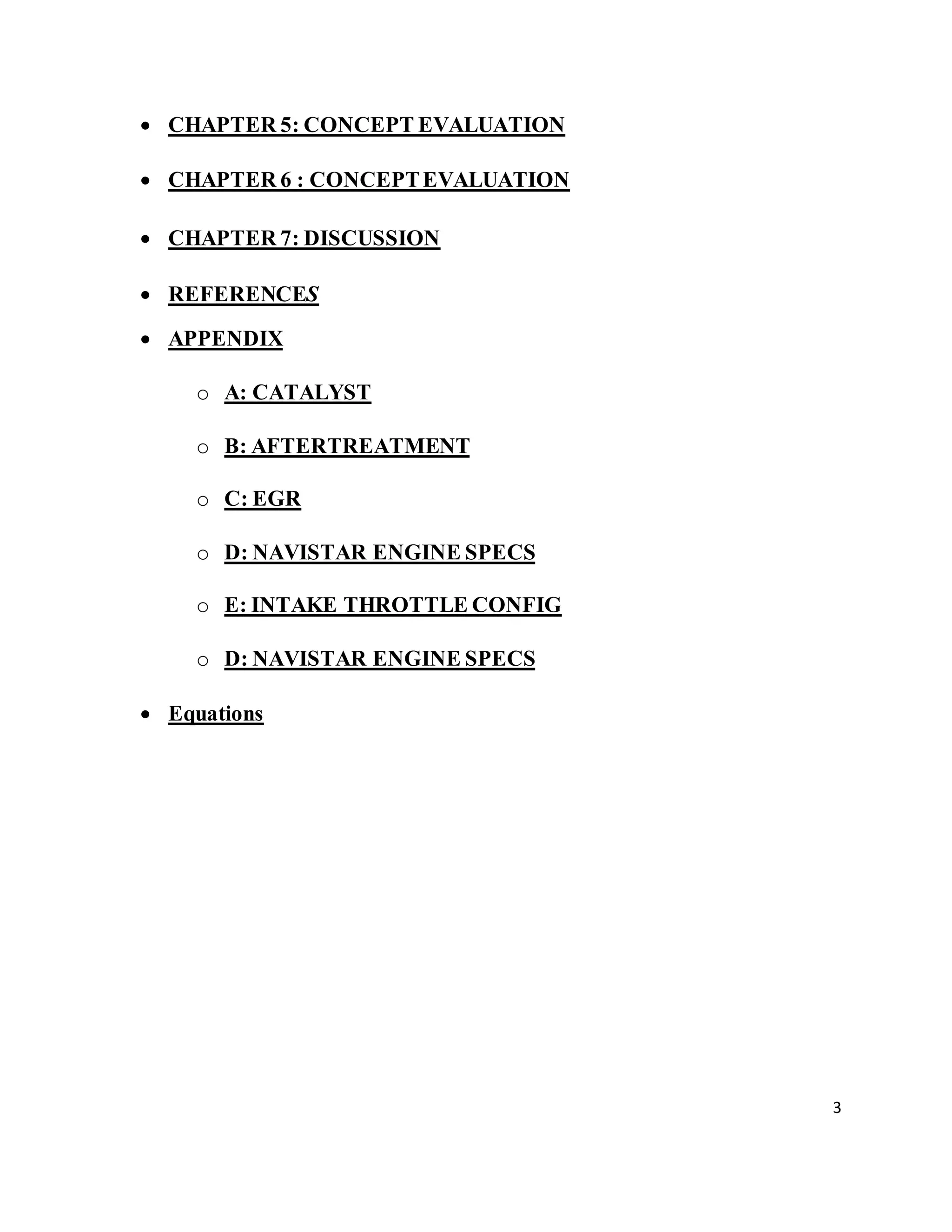

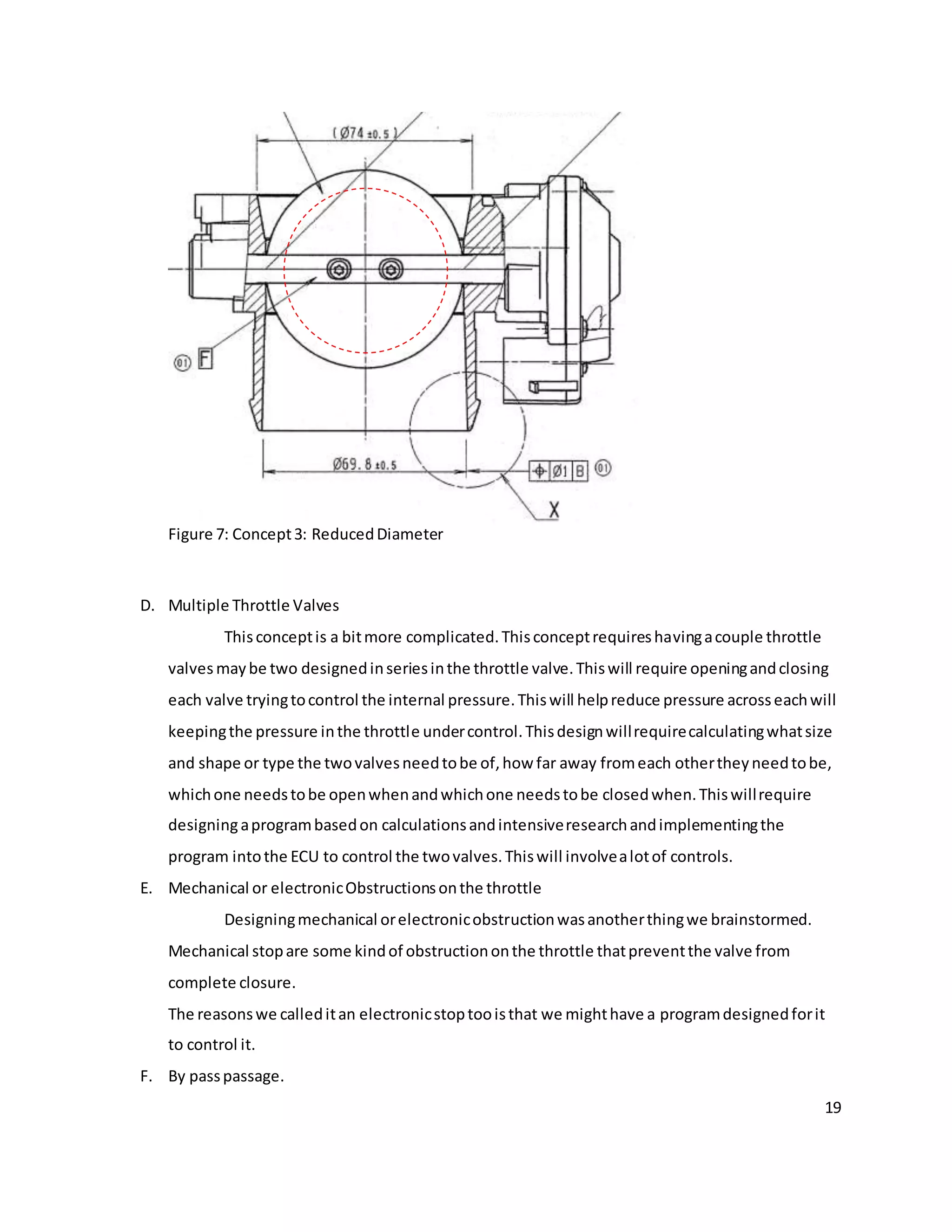

A. Orifice Plate

Orifice isnothingbutanopening,andthusa an orifice plate isa valve ora plate withan

opening.

Figure 5: Concept1: Orifice Plate

Thisis a valve whichbasicallyhasahole init.Where the hole needstobe designed?This

isnot determinedyet.Itcan be determinedwithfurthercalculations.

How doesan orifice plate help?

Since the Valve hasa hole inthe centerit allowsairincreasesairspeedsince ithastopass

througha smallerportion.Since the airhasto increase itsspeedtopassthrougha smallergap,

it resultsinreducedinternalpressurewhichmeansreducedDeltaP.ThusIf the DeltaP across

the valve iscontrolled,thenthiswill preventthe valve fromclosingdue tosuction.Some of the

calculationsthatwere lookedintothatwouldbe appliedtothisdesigntoprove whetherit

worksor nowis as follows.Thesecalculationswere basedoff of the original Fluidequationsin

Appendix [].

Orifice](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-16-2048.jpg)

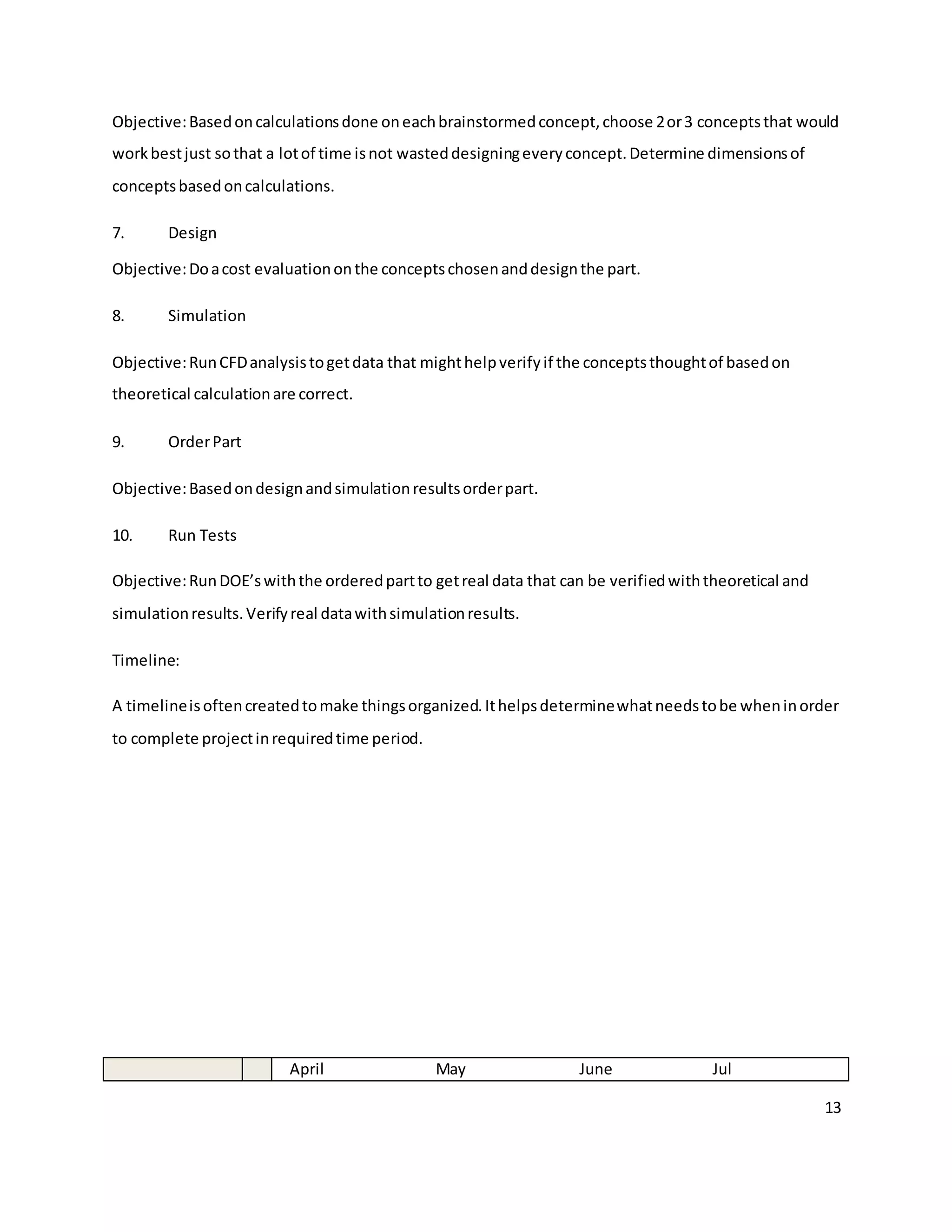

![17

The bestway to start aboutgoingaheadwiththisconceptwouldbe to talkto the

calibrationdepartmenttocheck,whatthe DeltaP requirementisata certainflow rate and at a

certainintake throttle angle.Thusthe minimumdiameterrequiredtomeetthe above targets

can be calculated.A numberof calculationscanbe done fordifferentcombinationsof flowrates

and intake throttle closure.The diameterof the openingcanbe determinedbasedoff of the

differentcalculationsperformed.

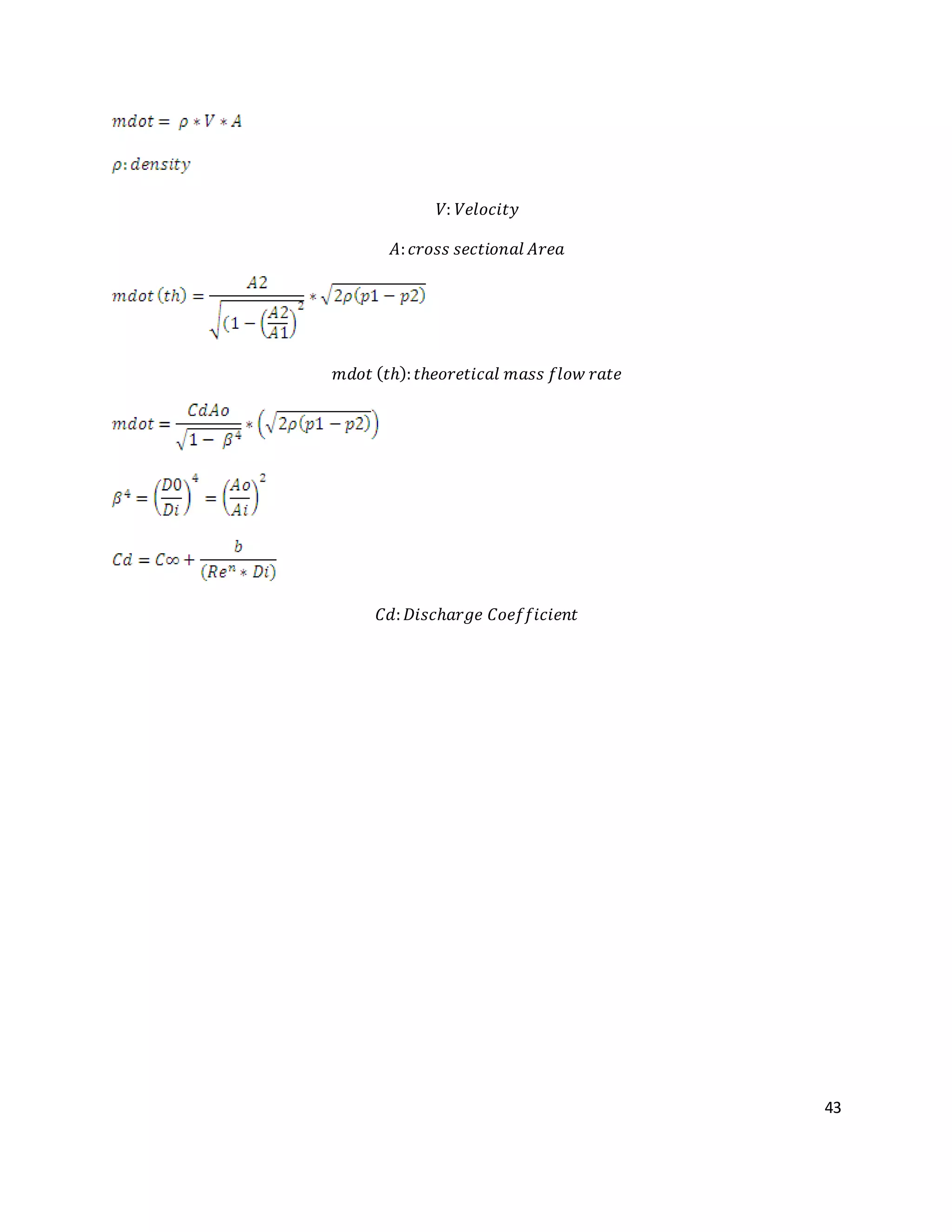

B. Oval shapedValve

The presentIntake throttle valve isroundshaped.The presentthrottle valve hasa

diameterof 68mm as seeninAppendix[].The orifice aroundthe valveis69.8mm.Thus there isa

onlya 1.8mm gap betweenthe orifice platein closedpositionandthe throttle orifice.Athigh

temperaturesthe valve tendstoexpand,becauseof whichduringarapidincrease inDeltaP,the

throttle tendstoshutdownat 80% valve closure insteadof closingcompletelyat100% closure.

Thus reducingthe shape bymakingitoval mightbe beneficial.Thiswillnotonlygive the valve a

greaterexpansiongap.Anotherthingthatneedstobe lookedintowhile creatingthisdesignis

that dimensionsof the valve needtobe calculatedtakingintoaccountthatevenafterexpansion

of the valve athightemperaturesthere will some gapforthe air to escape whichwill prevent a

rapidrise of pressure differential acrossthe valve thuspreventingthe valvefromshuttingdown

due to suctionfurtherpreventingthe enginefromchoking.](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-17-2048.jpg)

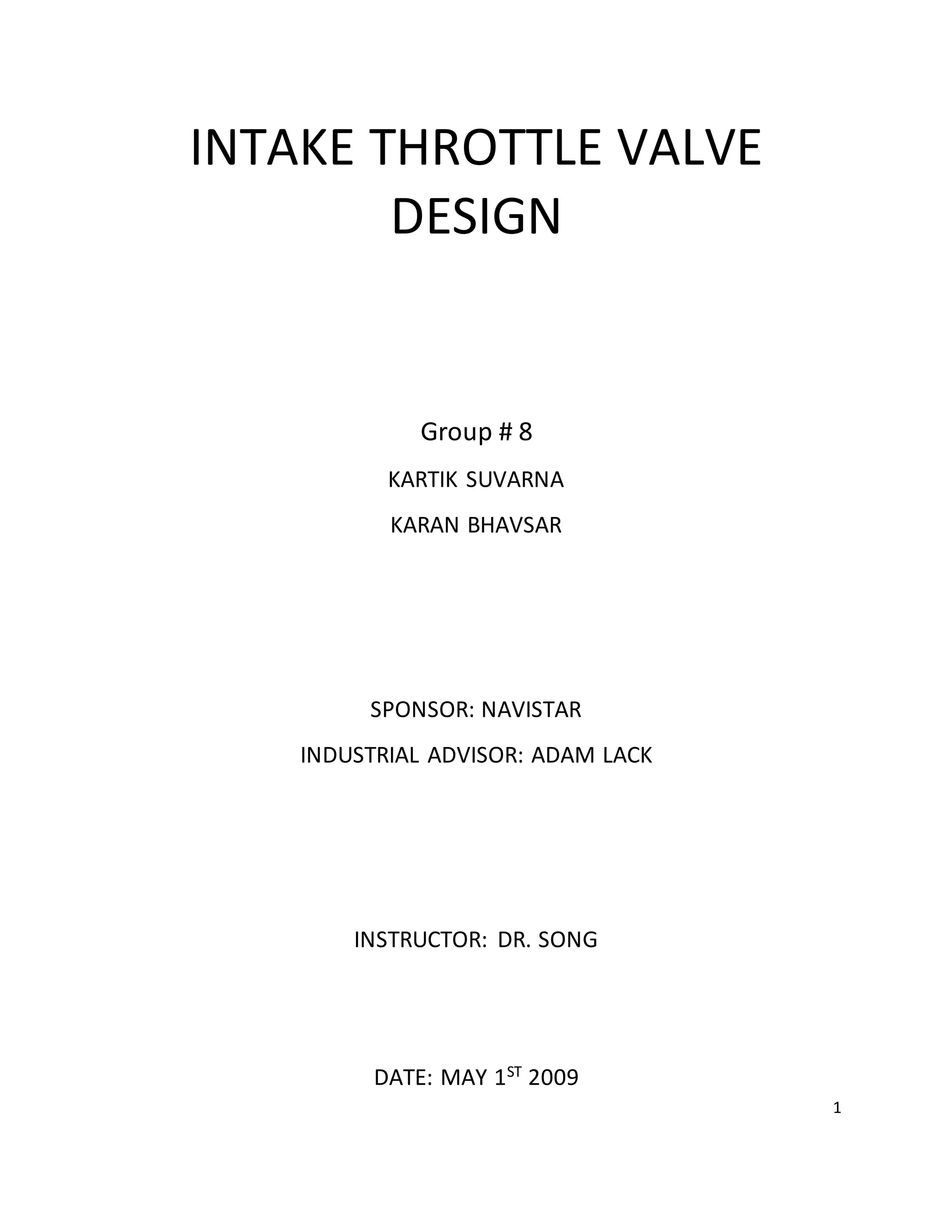

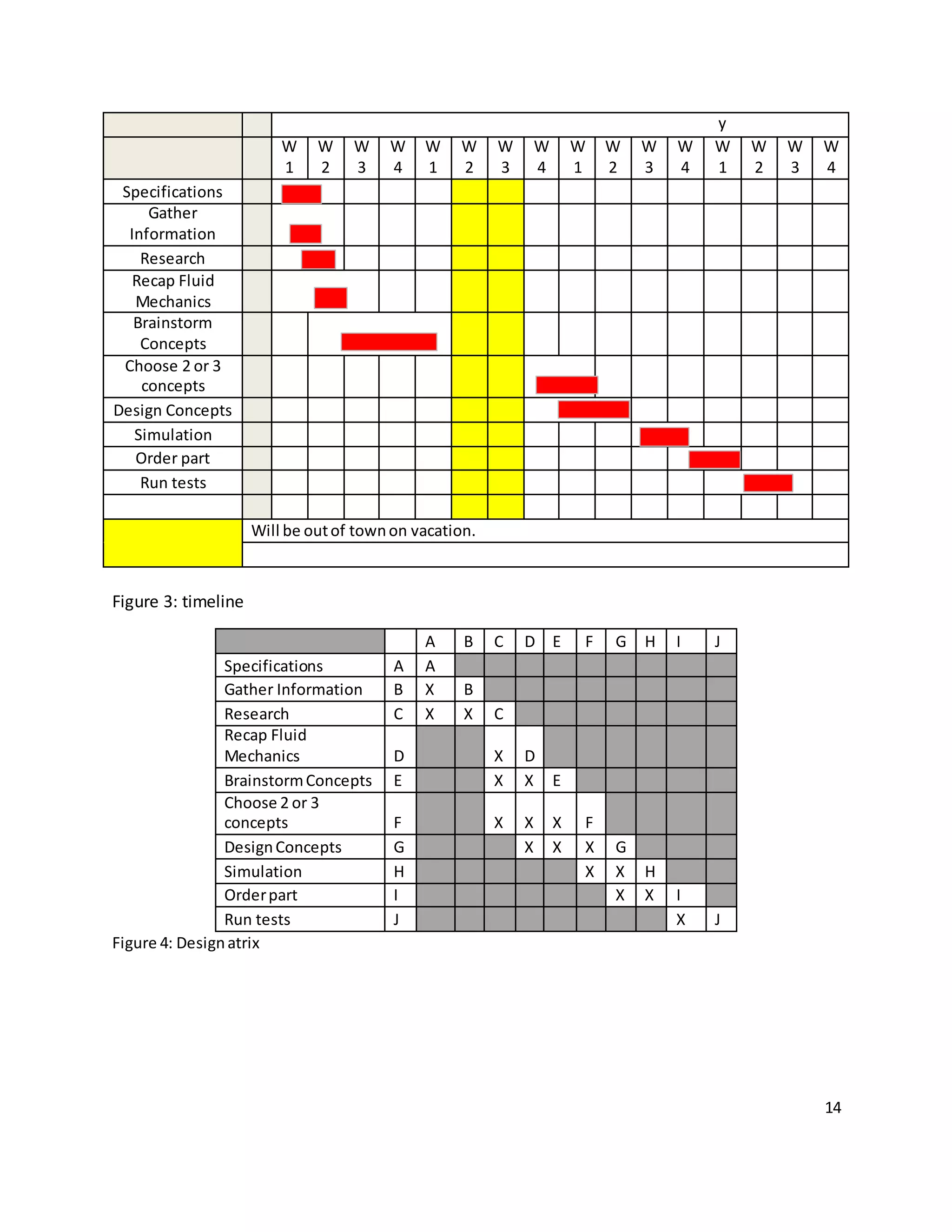

![29

APPENDIX C

EGR

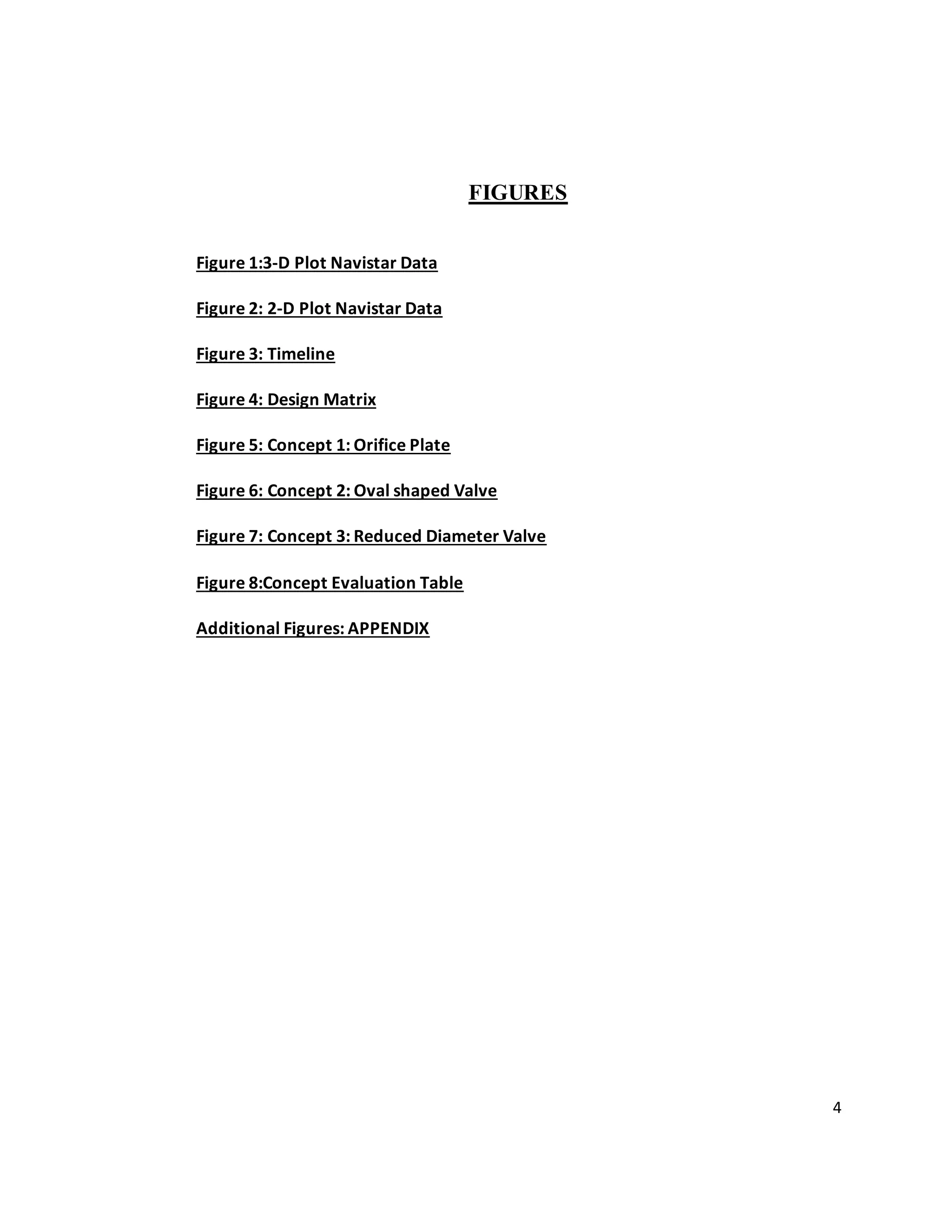

EGR Control Valves

The EGR rate inearlyEGR systemswascontrolledusingaproperlysized ratecontrolorifice,in a design

resemblingthe systeminFigure 1.While averysimple solution,the orifice wasnotable toprovide the

necessaryflexibilityincontrollingthe EGRrate. Withtime,the orifice wasreplacedbyacontrol valve,

whichacts as a variable orifice,thusprovidingthe necessaryflexibility.

EGR valvesutilize anumberof differentdesigns.Some valvesare apoppetstyle,whileothershave

adopteda rotary type design.Because of the mechanismof valve actuation,EGRvalvesare dividedinto

twocategories:

1. Pneumaticvalves,and

2. Electricvalves.

PneumaticvalveswerecommoninEGR systemsforlight-dutyvehicles.Diesel carsinthe 1990s utilized

almostexclusivelypneumaticEGRvalves,butnewerdieselcarmodelsincreasinglyadoptelectricEGR

valves.Electricvalve actuationwasthe standardmethodusedinEGRsystemsforheavy-dutyengines

since theirintroductioninthe 2000s.

Witha pneumaticEGRvalve,the electricactuatingsignal fromthe enginecontrol module(ECM) is

convertedbyan electro-pneumaticconverterintoapneumaticvacuumsignal.Whenthe pneumaticEGR

valve isexposedtovacuum(producedbyavacuumpump),itresultsinthe requiredvalve position.A

disadvantage of the pneumaticvalveisahysteresisinthe characteristiccurve betweenvalve opening

and valve closing[Flaig2000].

In electricEGR valves,the valve modulationisperformedusinglinearsolenoidsorsteppermotors.An

example EGRvalve forheavy-dutyenginesisshowninFigure 2.

Figure 2. Prototype of aProductionStyle EGR Valve

Lucas Control Systems](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-29-2048.jpg)

![30

Withthe electricEGRvalve,the ECMsendsa control signal to the electronicsintegratedinthe EGR

valve.Insome designs,aHall sensorisusedforpositionfeedbackforcontrol of the valve,resultingin

hysteresis-free openingandclosingof the valve andina linearcharacteristiccurve.ElectricEGRvalves

mustmeetdemandingoperational requirements:actuatingspeedsof lessthan50 ms at engine

compartmenttemperaturesof upto140°C were reportedinlight-dutyapplications[Flaig2000].

Controllingthe EGRvalve iseasilyaccommodatedthroughthe ECM.Many functionsare sharedbetween

engine andEGR valve control.Inputsof engine speed,torque (oftensubstitutedforwithintakemanifold

pressure),throttleposition,andintake manifoldtemperature are justafew of the sharedsignals

betweenbothengine andEGR control.

In some applications(e.g.,2004 7.3 literNavistarengine) anairflow sensorisusedtocontrol EGR rates.

At a givenspeedandloadcondition,the freshairsignal providedbythe airflow sensorforthe no-EGR

conditionisreducedbyopeningthe EGRvalve.The signal correspondingtothe reducedfreshairflowis

usedas feedback indicatingthe properEGRrate or leadingtofurtheradjustmentinEGRvalve position

to obtaina predeterminedEGRrate.In general,aproductionEGR systemmaynotneedfullydedicated

sensors,butmayshare control signalswithexistingsensors.We willreturntothe topicof EGR control

later.

The EGR valve isoftena separate componentinstalledinthe exhaustpiping.Insome designs,however,

the valve can be integratedwithvariouspartsof the engine.A valve integratedwiththe exhaust

manifoldis showninFigure 3[Haerter1994].

Figure 3. EGR Valve/IntakeManifoldIntegral Design

EGR Coolers

The heat absorbedfromthe combustionprocessisproportionaltoEGR rate,its specificheat,andthe

difference betweencombustionandEGR temperatures.Hence,coolingthe EGR streamallowsfor

greaterheatabsorptionfromthe combustionprocesswhichleadstoalowerrate of NOx formation.In

addition,coolerEGRoccupieslessvolume inthe inletsystem.LowerEGRvolume displacesasmaller

fractionof freshfilteredintakeair,thusdisplacinglessO2,whichhelpsmaintaincombustionefficiency.](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-30-2048.jpg)

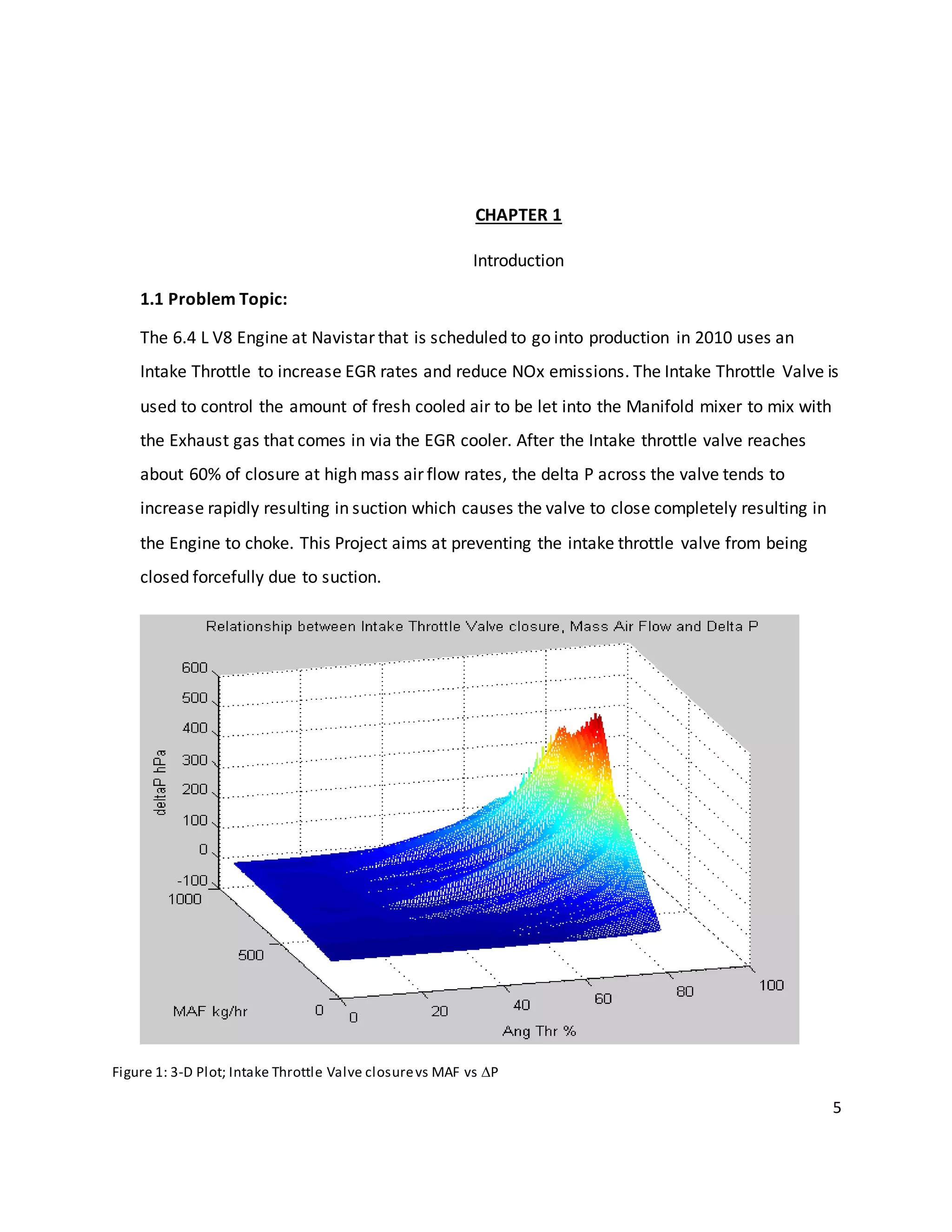

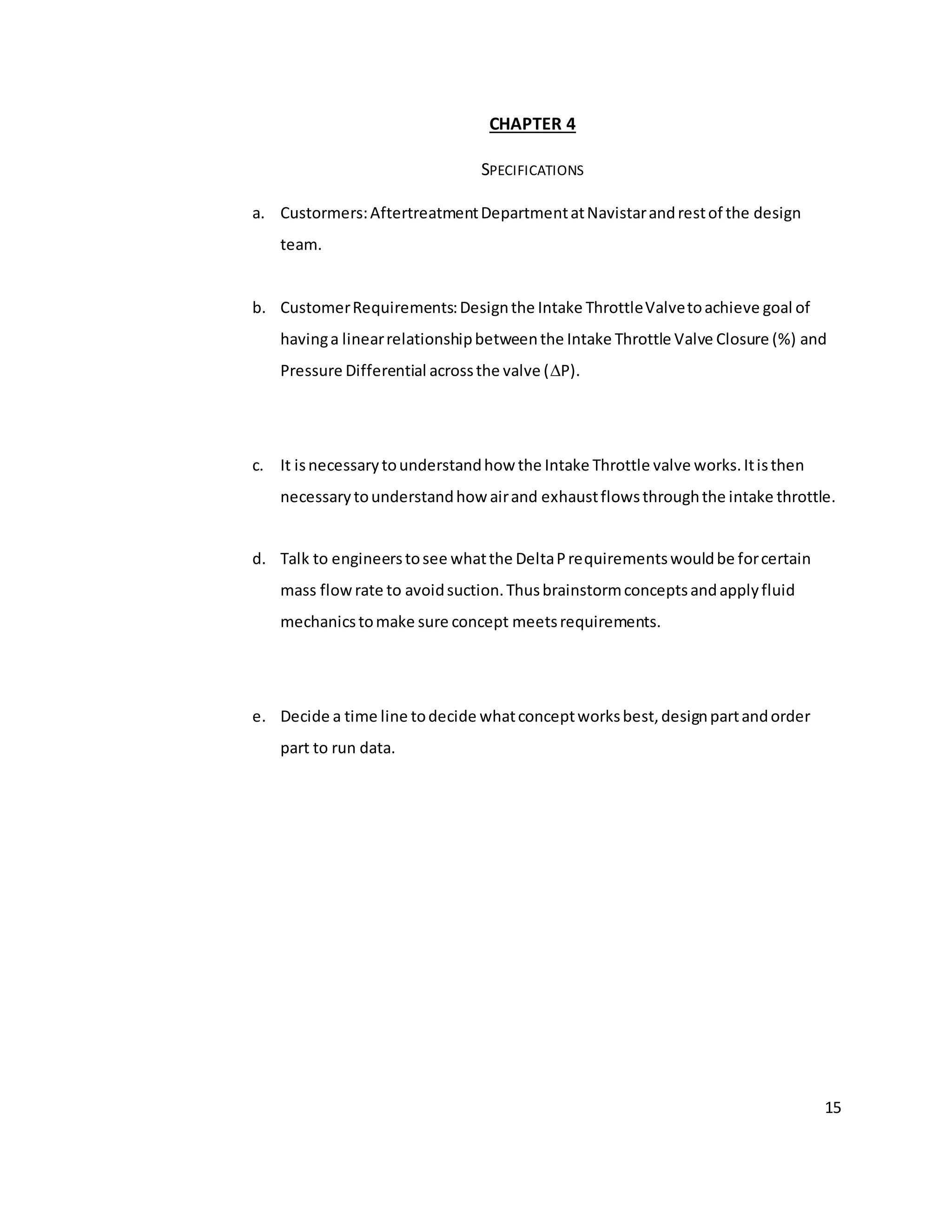

![31

A schematicrepresentationof anEGR coolerisshowninFigure 4. A startingpointformany EGR cooler

designshasbeenthe shell-and-tubeheatexchanger.Exhaustgasflowsthroughthe tubesof the heat

exchangerwhile the coolant—jacketwater—flowsinthe shell.

Figure 4. SchematicDiagramof EGR Cooler

Coolereffectiveness ismeasuredbythe ratioof the actual heattransfer across the coolerto the

maximumheattransferthatwouldbe potentiallypossible consideringthe temperaturesof the exhaust

gas and the coolant(i.e.,whenthe outletgastemperature becomesequaltothe inletcoolant

temperature):

(1)ε= Q/Qmax = (Tg,in - Tg,out)/(Tg,in - Tc,in)

Heat exchangergeometrymayneedtobe consideredinapplyingEquation(1).Onlycounterflow heat

exchangers,suchasthat showninFigure 4 (butof infinitelengthorinfinitelyhighheattransfer

coefficient),couldprovidean effectivenessof 1 usingthisequation.Forparallelflow coolers,Tc,in could

be replacedbyTc,out to representthe lowesttemperature towhichthe exhaustgascouldbe cooled.

Coolerswithmixedflowpatternscanbe designed,wherethe minimumpossible outletgastemperature

issomewhere betweenTc,in and Tc,out.

However,if one considersthe heatexchangertobe a blackbox,thenEquation(1) couldbe appliedto

any heatexchangerregardlessof geometry.Itwouldthencompare anygivenheatexchangerdesignto

the infinite lengthcounterflowarrangementthatwouldinprinciple provide maximumheattransfer.

Thisapproach isoftentakenforEGR coolers[Hoard2007][Kowada 2006].

An example temperature profileandthe effectof coolantflow rate througha parallel flow shell-and-

tube EGR coolerare showninFigure 5 [Charlton1998]. In thiscase,as the coolantflow rate decreases

the effectiveness(relative tothe infinite lengthcounterflow arrangement)dropsfromabout81% to

72%.](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-31-2048.jpg)

![34

Figure 8. FlatTube Style EGR Cooler

(Caterpillar2007 C15 ACERT engine)

Compactnessratio quantifiesthe heattransfersurface areaperunitvolume of the heatexchanger.In

some EGR coolers,more compactdesignisachievedthroughthe use of finsonthe gasside.Tube andfin

designscanhave compactnessratiosupto about 330 m2

/m3

.Plate andfincoolers—suchasthatshown

inFigure 9—can have compactnessratiosabove 1000 m2

/m3

.

Figure 9. CompactEGR CoolerAssemblyforLight-DutyApplications

(Source:Pierburg)

The EGR coolerinFigure 9, intendedforlight-dutyapplications,ismade fromdie castaluminum[Breuer

2007]. The exhaustgasfollowsaU-shapedflow patternthroughthe coolershell andpastthe fins.The

coolershell issurroundedbyenginecoolant.Thiscompactdesignisalsoveryefficient,withheat

transfercoefficientsonthe orderof 3000 W/m2

Kon the coolantside,andon the orderof 300 W/m2

Kin

the gas. Highheat transferratesare alsostimulatedbythe use of aluminum, whichhasa significantly

higherheatconductivitythanstainlesssteel.

Two-Stage Cooling.The practical lowtemperature limittowhichanEGR coolercan cool the recirculated

exhaustgaswill be somewhathigherthan the inlettemperature of the coolingmedium.ForanEGR

coolerusingengine coolantasa coolingmedium,thistemperature will be limitedbythe engine coolant

temperature—usuallyinthe range of 70-90°C. If lowerEGR temperaturesare required,asecondcooler

that usesambientairas a coolingmediumwouldbe required.Thisapproach—takenbyInternational on

some of theirUS 2007 enginesandbyScaniaforits Euro V engines—presentssomechallengessuchas

minimizingthe effectsof condensedwatertopreventcorrosionandfreezing.](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-34-2048.jpg)

![35

CoolerBypass. CoolingEGR may notalwaysbe desirable.Forinstance,incoldweatherconditionswhere

EGR iscooledbelowthe dewpointtemperature,condensate mayformandmix withexhaustcontaining

sulfurandnitrogencompounds.The mixture of condensate andexhaustcanproduce acidsthat couldbe

corrosive tocomponentsof the EGR systemaswell asotherparts of the engine.Condensationof sulfur

speciesinEGR coolersandthe associatedcorrosionissueshave beenthe subjectof anumberof studies

[McKinley1997][Kreso1998b].

Some designsallowforbypassingthe EGRcoolerin coldtemperature aswell asat some driving

conditions,suchasidle orno load.Thispractice has oftenimprovedidle/noloadandpartloadfuel

economy,aswell asreducingHC andCO emissions.Itisalsoaimedatreducingthe formationof acidic

condensate thatmayimpairengine componentsdurability.A bypassarrangementalsoallowsbetter

control of EGR temperature byallowingforthe mixingof differentproportionsof cooledanduncooled

EGR. A coolercore withan integratedbypasspassage isshowninFigure 10[Beck2007]. A flapat the

inletof the coolerdirectsEGR to eitherflow throughthe coolingpassagesorthe bypasspassage.

Figure 10. EGR CoolerWithIntegratedBypassPassage

EGR coolerscanbe subjecttoconsiderable thermalstressfromthe highheatload.Toensure a long

service life,the housingstructuresof these coolerscanbe fittedwithanexpansionjoint,suchasan

expansionbeadora bellowsstructure,toprovide axial compensation.

Fouling.Foulingof the EGR coolerisa majorconcernbecause itcontributestolowercooler

effectiveness,aswell asincreasedpressureloss.Experimentsconductedonprototype coolershave

shownthat effectivenessdegradationisusuallylimitedtothe first20 to 30 hoursof use.The most rapid

drop of coolereffectivenessoccurswiththe cleancooler,inthe initial hoursof operation(thisisalso

apparentfromFigure 7 and Figure 11).

Foulingoccursprimarilyasa resultof the depositionof diesel particulate matter,aswell ascondensed

and/orpyrolysedhydrocarbons.Foulingtendstobe more severe inthe presence of “heavywetPM”,

whichismore common at lowNOx engine calibrations[Hoard2007]. The contaminantsare depositedon

the wallslargelydue tothermophoreticallyaugmentedconvective diffusion.Owingtothe insulation

effectof the depositlayer,the thermophoreticeffectlevelsoff whenthe depositbuildsup,leadingtoa](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-35-2048.jpg)

![36

fallingrate of deposition.The resistance toheattransfercausedbyfoulingwillusuallyreachasteady-

state value forwhichempirical correlationsexist.One suchcorrelationis[Grillot1997]:

(2)R = 1.094 Cpart V-1.14

((Tg - Ts)/Tg)0.7

where:

R - steadystate foulingheattransferresistance,m2

K/W

Cpart - particle concentration,g/m3

V - gas flowvelocity,m/s

Tg - gas temperature,K

Ts - surface temperature,K.

A numberof approachescan be takento minimize the effectsof foulingincludingthe selectionof

appropriate geometriesthatinhibitexcessiveaccumulationof foulingmaterial andaddingextracapacity

that isintendedtobe lostto foulingduringservice of the cooler.Increasingflow velocitythroughthe

coolerand loweringthe temperature difference betweenthe gasandthe heatexchangersurface—as

suggested byEquation(2)—mayalsobe usedtominimizefouling.

An effective measure tocontrol foulingistoreduce the concentrationof particlesandother

componentsinthe EGR that may accumulate inthe heatexchanger.Forenginesequippedwithadiesel

particulate filter(DPF),anLPLEGR configurationcanbe used,where cleanexhaustgasisrecirculated

fromthe outletside of the filter(thisapproachwastaken,forexample,in2007 CaterpillarACERT

onroadengines).However,foulingmayremainaproblemforenginesthatrecirculate exhaustgasfrom

the exhaustmanifold.While aparticulate filtercouldbe placedinthe EGR line upstreamof the cooler,

the problemsof pluggingandkeepingthe filtercleanpresentasignificantchallenge.

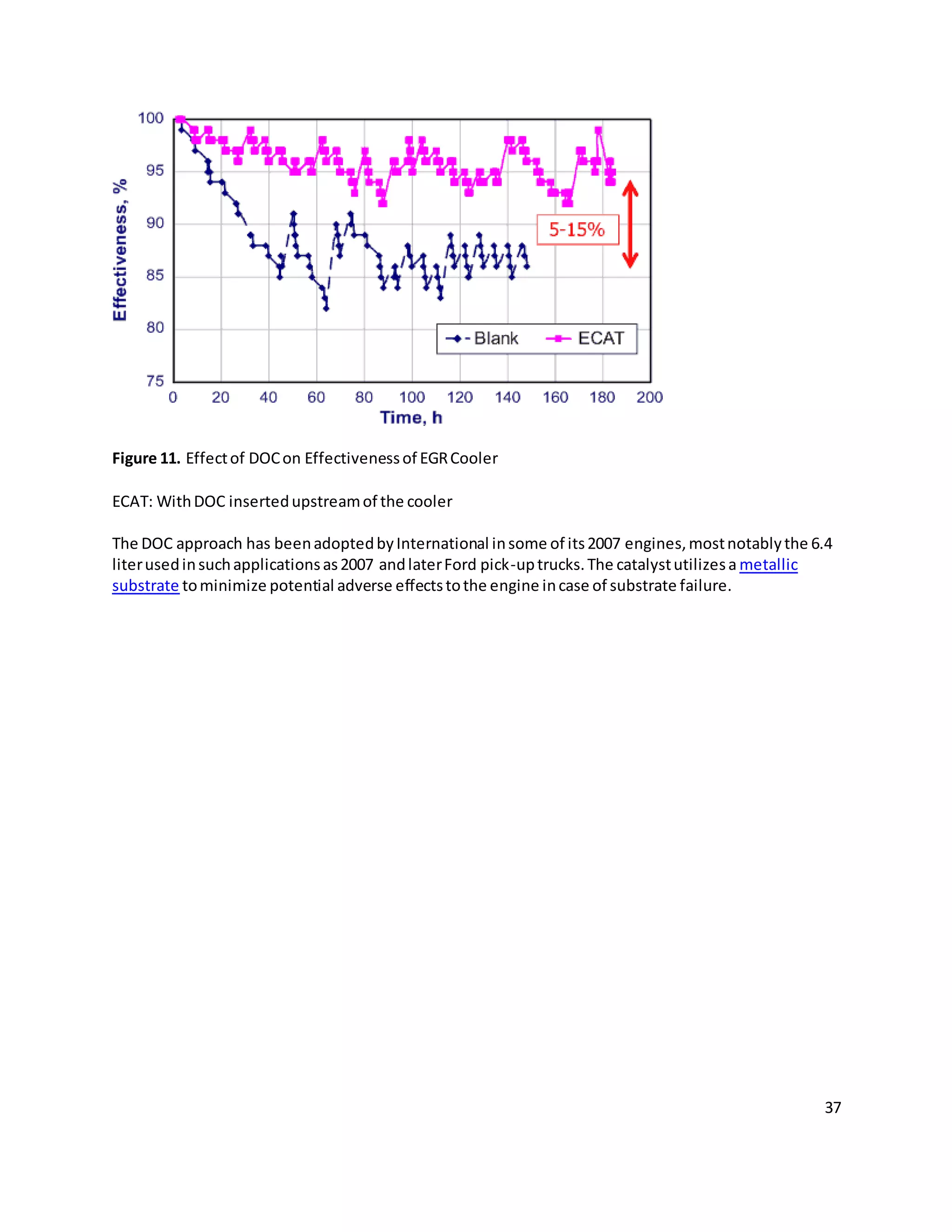

A more practical approach isto inserta diesel oxidationcatalyst(DOC) intothe EGRline upstreamof the

cooler.While notprovidingthe same levelof foulingprotectionasafilter,the catalystcansignificantly

reduce degradationof heattransfereffectivenessinanEGR cooler,as illustratedinFigure 11[Tyo

2007][Hoard 2007]. The coolereffectivenessdatawascollectedoveranengine cycle speciallydesigned

to testEGR coolerfouling.The DOCcan alsoprovide anadditional benefitof protectingthe EGRvalve

fromsticking.](https://image.slidesharecdn.com/mee481finalreport-141116183406-conversion-gate01/75/Senior-Design-Project-B-S-Mechanical-Engineering-ITV-Research-and-analysis-36-2048.jpg)