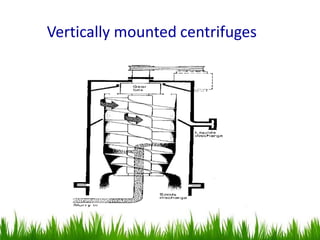

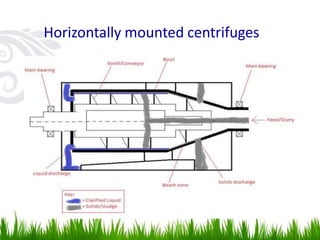

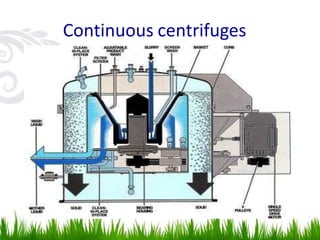

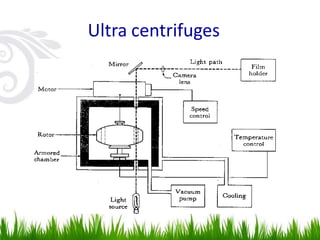

This document discusses different types of centrifuges used in separation processes. It describes vertically mounted centrifuges that use a perforated basket to separate solids from liquid suspensions. Horizontally mounted centrifuges introduce material at the center of a rotating horizontal cylinder to separate solids. Continuous centrifuges provide high capacity separation for large particle sizes in continuous processes. Ultra centrifuges can spin at very high speeds generating high accelerations for analytical and preparative applications.