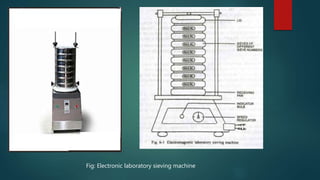

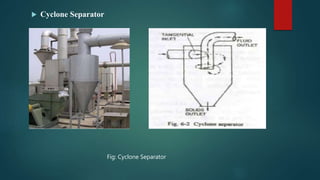

This document discusses different techniques for separating particles by size, including sieving, cyclone separation, air separation, and elutriation. It defines various powder sizes according to the Indian Pharmacopoeia standards. Sieving is described as the primary method, where powders are separated based on which sieves they pass through. Cyclone separation and air separation use centrifugal forces to separate particles based on size and density. Elutriation suspends particles in a moving fluid to separate fractions based on particle density and size.