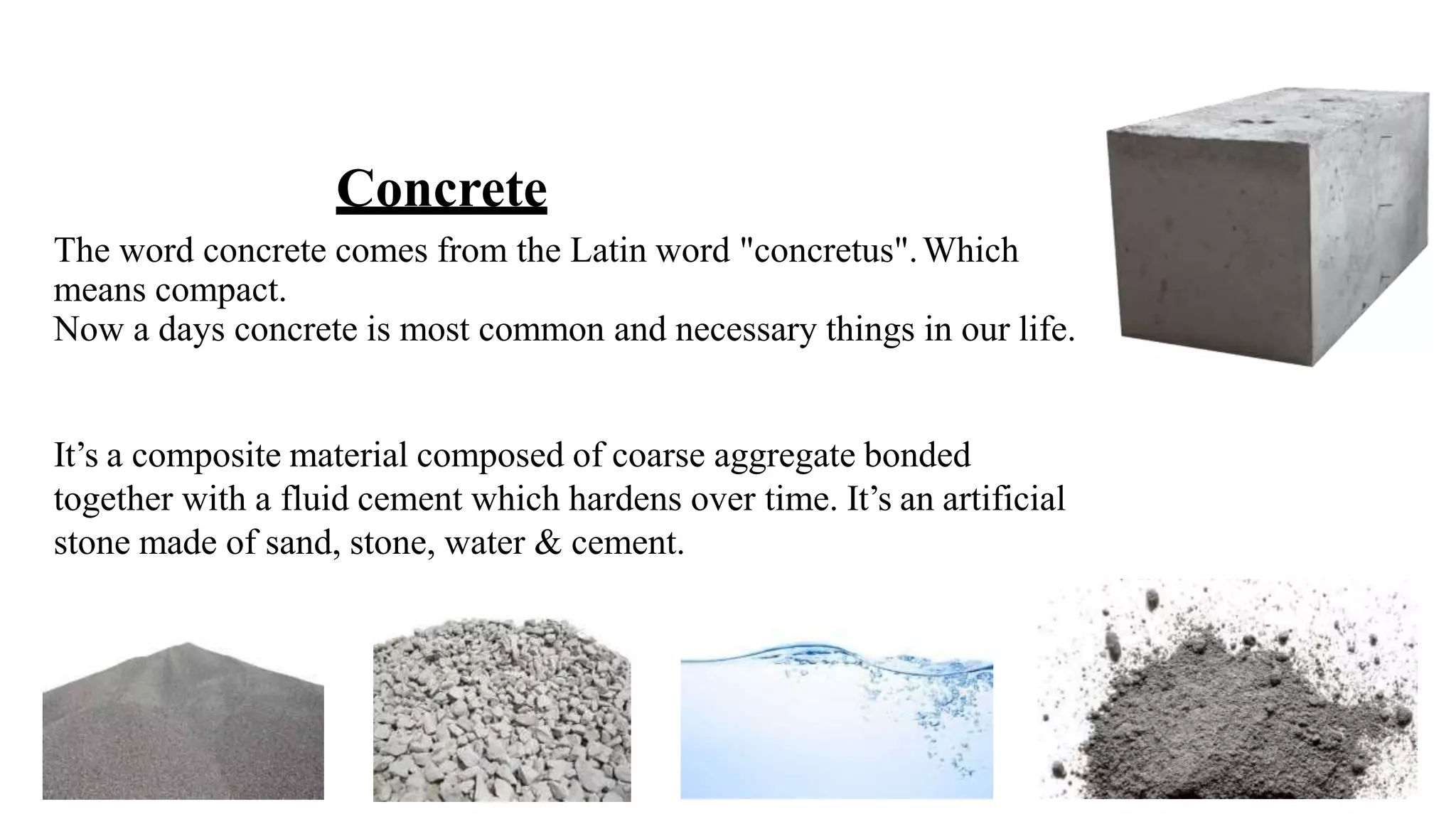

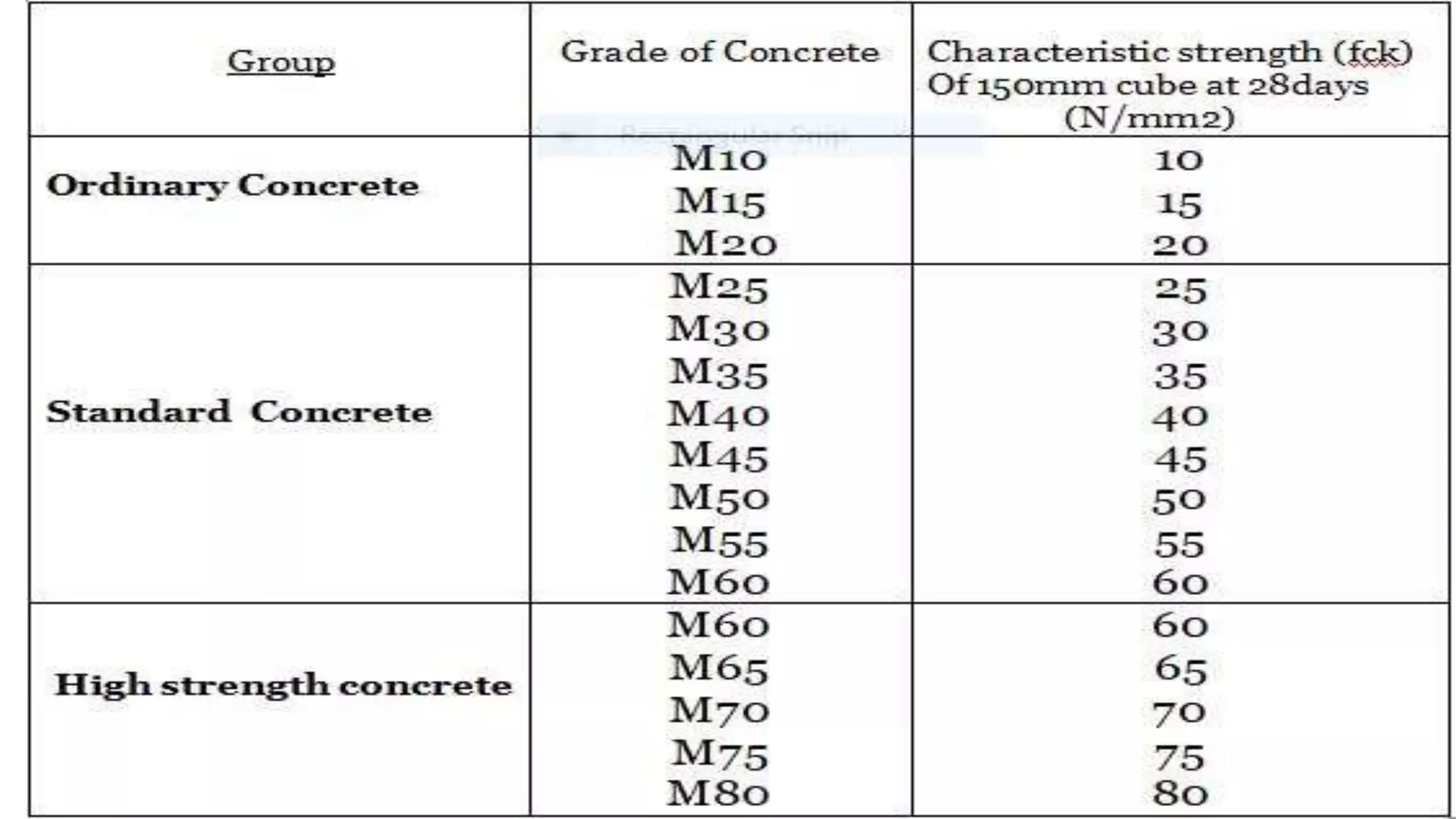

This document provides information about concrete, including its definition, classification, mix design, tests, and qualities. It can be summarized in 3 sentences:

Concrete is summarized as a composite material made of cement, sand, stone and water that is widely used in construction. The document outlines various types of concrete based on binding material, design, and purpose, and discusses factors in concrete mix design, methods of mixing, placing, curing, and tests to determine qualities like strength, workability, and water tightness. Modern concrete is the most widely used man-made material and the document provides its classification and testing methods.

![VEE-BEE CONSISTOMETER TEST

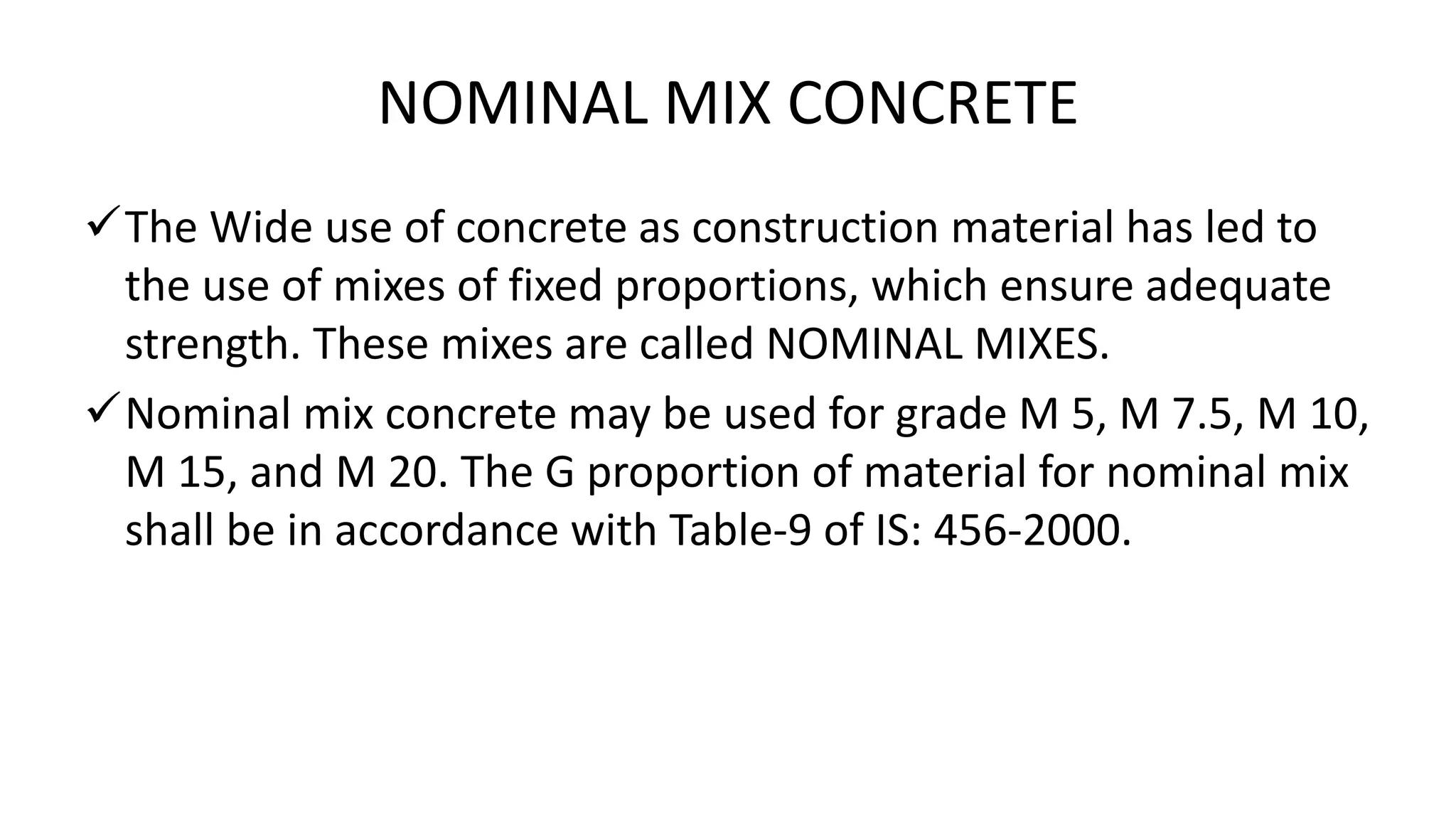

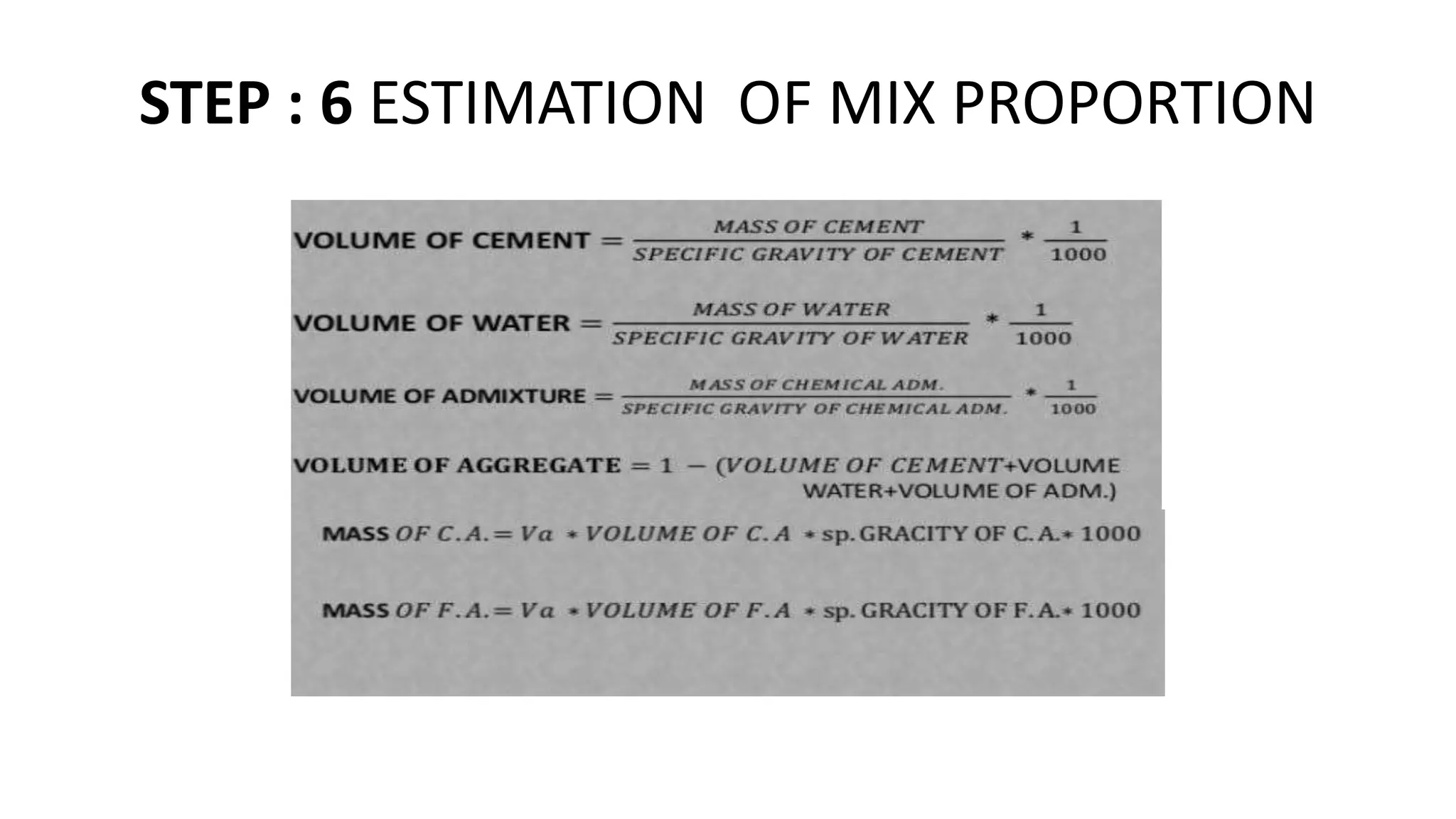

• This test determines the time required for transforming, by vibration a

concrete specimen in the shape of a conical frustum into a cylinder.

• Apparatus consists of a vibrator table resting upon elastic supports, a metal

pot, a sheet metal cone, open at both ends, and a standard iron rod.

• Slump test is performed in the cylindrical pot of the consistometer which is

a good laboratory test [ONLY] to measure indirectly the workability of

concrete.

• The Slump cone is placed in the cylindrical pot, and slump is noted. Then

the electrical vibrator is switched on and the TIME TAKEN for the concrete

to spread out in the cylindrical pot is noted in seconds and workability is

measured in VEE-BEE degree.](https://image.slidesharecdn.com/finalconcrete-211031080133/75/Concrete-and-its-information-49-2048.jpg)

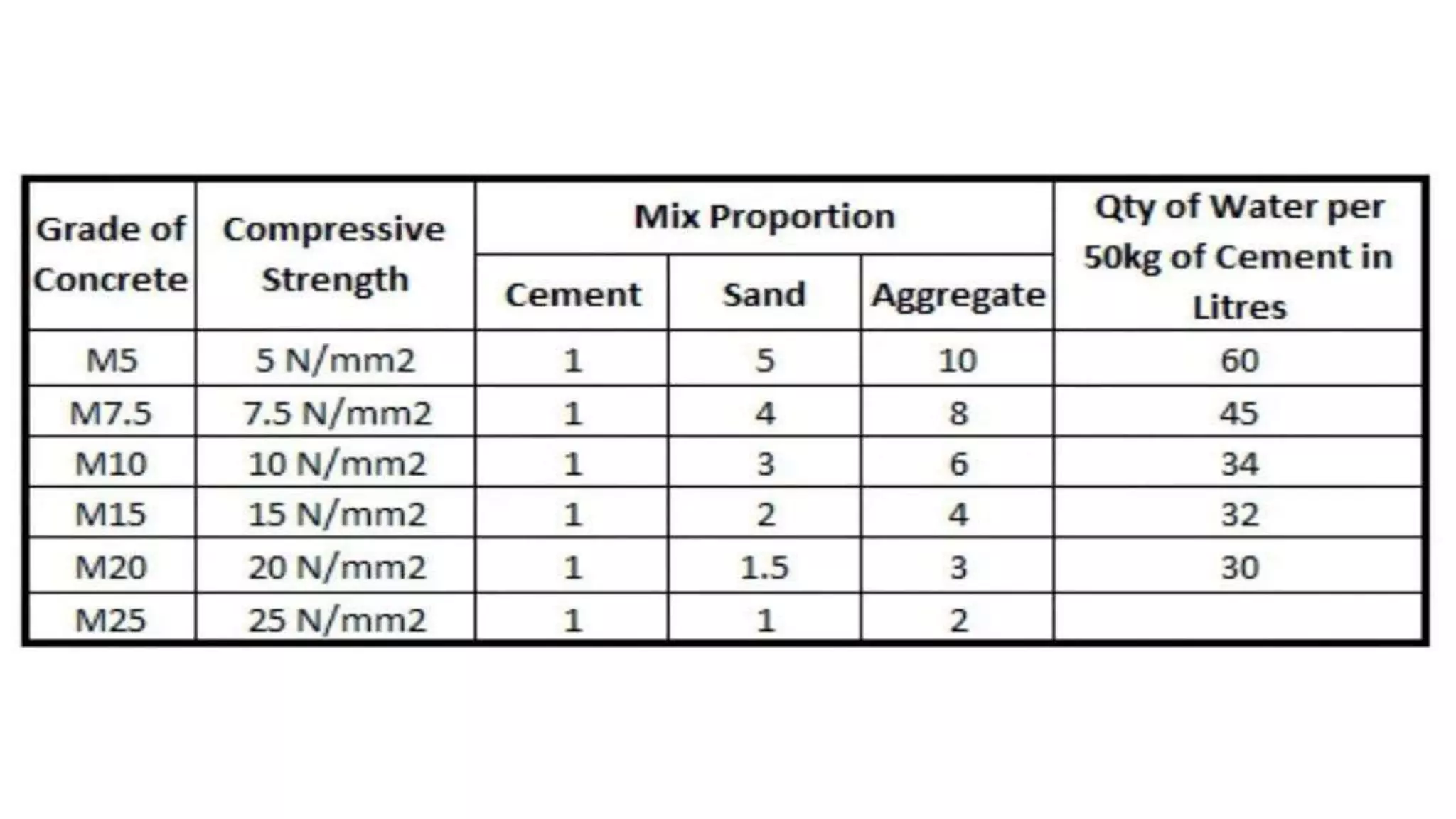

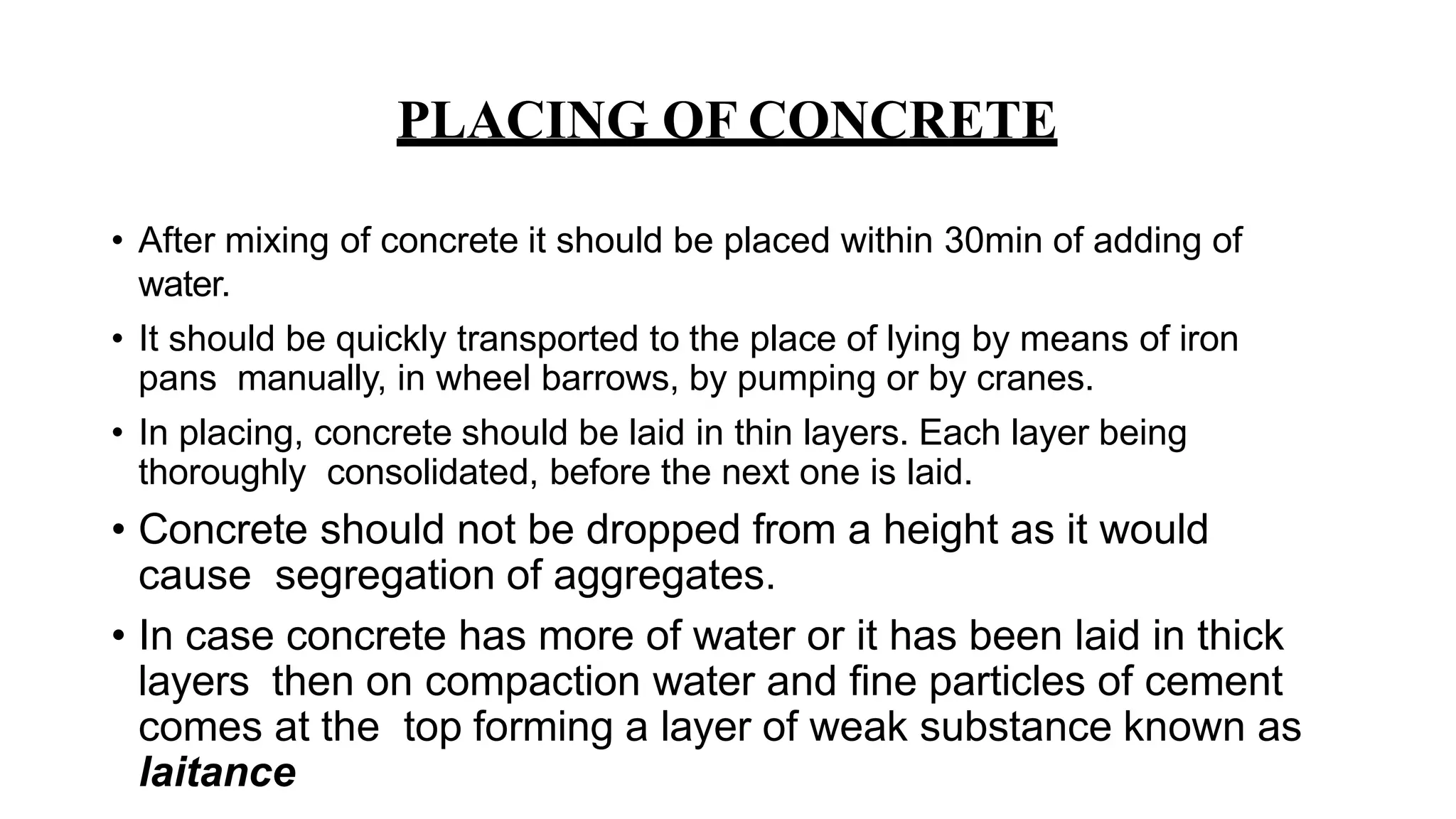

![COMPRESSIVE STRENGTH TEST

• Cement, fine aggregate and Coarse aggregate (upto 38mm) to be

used for making concrete are weighed in the required ratio to be

used in field and are thoroughly mixed, by adding requisite amount

of water until the concrete appears homogeneous.

• The test SPCIMENS are cast in the required sizes of cubes, 150mm x

150mm x 150mm or cylinders of 150mm diameter and 300mm

height. [D/H = 1/2]

• Test specimens are stored at room temperature for 24hrs from the

time of addition of water to dry ingredients.

• After this time specimens are removed from the moulds and placed

in water and kept there until taken out just before the test.](https://image.slidesharecdn.com/finalconcrete-211031080133/75/Concrete-and-its-information-51-2048.jpg)