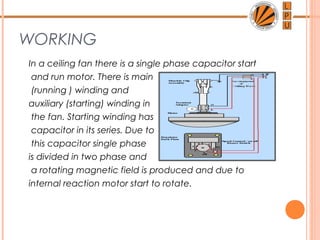

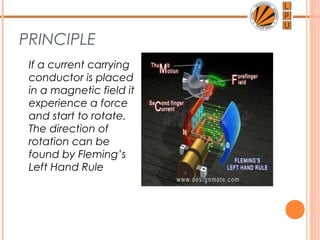

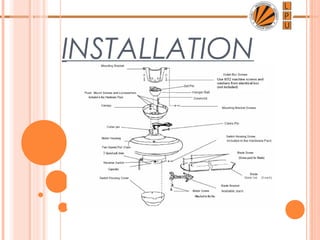

This document provides information on ceiling fans, including their history, working, components, installation, and airflow direction for different seasons. It discusses how the first electrically powered ceiling fan was invented in 1882. It also explains the key components of a ceiling fan, such as the electric motor, blades, canopy, and downrod. The document gives steps for installing a ceiling fan, including attaching the hanger bracket, lifting the fan onto it, and installing the safety cable. It recommends using the ceiling fan on medium-fast speed in summer to feel cooler and on a slower speed in winter to keep heat circulating.