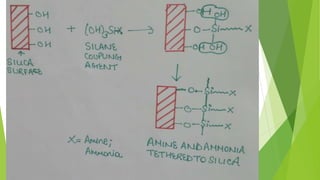

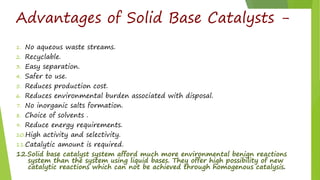

This document discusses solid base catalysts as a green approach for chemical synthesis. It describes various types of solid bases including hydrotalcites, zeolites, and amines immobilized on silica. Hydrotalcites have basic sites in the interlayer space and can catalyze aldol condensations and ionone synthesis as a replacement for NaOH. Zeolites with exchanged alkali cations or loaded metal oxides also exhibit basic properties and can catalyze reactions like the Knoevenagel condensation. Immobilizing amines and ammonium groups on silica via grafting produces heterogeneous basic catalysts. Solid bases offer advantages over liquid bases like recyclability, easy separation, and generating less waste

![SOLID BASES

The solids having the sites which serve as a Bronsted base and/or

Lewis base are called SOLID BASES. These are used in place of liquid

bases like NaOH, KOH etc.

AH B

- A

- BH

A B A B

A] Bronsted-Lowery concept of conjugate acid -base pair-

B] LEWIS -Base concept -

lewis base

BASE Conjugate-acid

The solids having the sites which serve as a Bronsted base and/or

Lewis base are called SOLID BASES.](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-3-320.jpg)

![With Proton Abstraction- On the surface of solid bases, there are

specific sites or centers, which function as a base. Basic

sites(centers) abstract protons from the reactant molecules(AH) to

form a carbanion(A-).Here the basic site act as a bronsted base.

AH B

-

A

- BH

BASE Conjugate-acid

Activation of reactants on SOLID BASES- It occurs by

two ways-

1]

2] Without Proton Abstraction- Reactants such as ketones and

aldehydes are often activated by bases without proton transfer, here

the basic sites B- act as lewis base. This kind of interaction is important

in many base-catalysed reactions such as Aldol-

Condensations,Knoevenagel condensation and hydrogen transfer

reactions.

C O B

- H3C

B

O-](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-4-320.jpg)

![PhCH2CN CH3I NaOH NaI H2O

1] CONVENTIONAL METHOD - The Methylation of Phenylacetonitrile with

Methyl Iodide proceeds in the presence of Bases under a Phase-Transfer

Condition.

SN2

REACTION

PhCH(CH3)CN

2] GREEN APPROACH - The methylation of Phenylacetonitrile by using methanol

or Dimethyl carbonate as the methylating agent and alkali-exchanged zeolites as

catalysts. The reaction can be performed in vapour phase.

PhCH2CN CH3OH

ZEOLITES

Phenylacetonitrile Base(needed in

stochiometric amounts)

Toxic

reagent

Inorganic salt(disposing

problem)

PhCH(CH3)CN H2O

Phenylacetonitrile

SN2 REACTION

COMPARISON B/W CONVENTIONAL

AND GREEN METHODS -

Green by product](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-6-320.jpg)

![O O

NaOH

CH2

CH3

H

O O

O

O

-

OH-

-

O

H H

O

O H

α

β

H H

-OH-

NaOH

Δ

O

α

β

H

H

H

O

-H20

O

β

H

α

Acetone

Enolate

3] Protonation

4] Dehydration α,β-Unsaturated ketone

1] Abstraction of proton 2] Enolate attack

General Mechanism Of

ALDOL-CONDENSATION-](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-8-320.jpg)

![1

2

ALDOL CONDENSATION BY HYDROTALCITE AS A

BASE IN PLACE NaOH

CH2OH

2-Ethylhexanol

[Methylisobutylketone]

(MIBK) and 2-ethylhexanol, the precursor of the PVC

plasticizer, and are used in Paints.](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-11-320.jpg)

![O

OH

-

Pseudoionone

Acetone

Citral

CH CHCOCH3

CH CHCOCH3

OR

CH CHCOCH3

β - ionone

H+

+

Conventional Method - IONONE

SYNTHESIS BY ALDOL-CONDENSATION

[Aldol Condensation]

60% conv.

80% selectivity

1

2

3

4

α - ionone

Me

O

Me

Me Me

Me

Me

CHCCH3

O

Me

Me

Me

CH

Me

Me Me

H

H

α

β

α

β

α

β

CH CHCOCH3

CYCLIZATION](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-13-320.jpg)

![O CH CHCOCH3

Pseudoionone

Acetone

Citral

CH CHCOCH3

OR

CH CHCOCH3

α - ionone β - ionone

[Aldol Condensation]

>95% conv.

70% selectivity

HYDROTALCITE

HYDROTALCITE method for the

synthesis of IONONES

1

2

Ionones are used in perfume

industry.

CHO

α

β

α

β](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-15-320.jpg)

![2) Zeolites as Solid Bases –

Zeolites are crystalline aluminosilicates with pores of molecular dimensions.

General formula = M[(AlO2) x(SiO2) y].MH2O

AlO2and SiO2 are fundamental units sharing oxygen ions to form tetrahedral Al04

and SiO4 building blocks for zeolite unit cell.](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-16-320.jpg)

![Catalysis by solid bases [recovered] [autosaved]](https://image.slidesharecdn.com/catalysisbysolidbasesrecoveredautosaved-210612140910/85/Catalysis-by-solid-bases-recovered-autosaved-27-320.jpg)