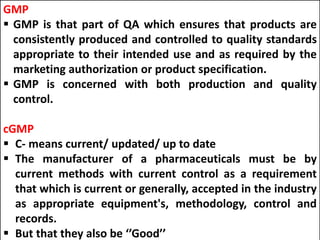

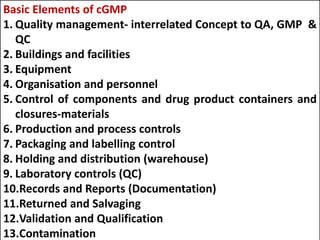

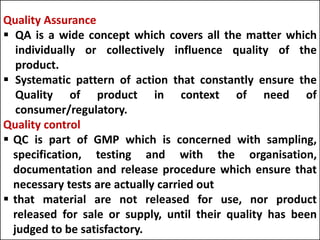

This document provides an overview of current good manufacturing practices (cGMP) for pharmaceuticals. It discusses that medicines must be of the right quality to be effective and safe for patients. cGMP helps ensure consistent production and quality control of medicines. The document outlines the basic elements of cGMP, including quality management, facilities, equipment, organization, production processes, packaging, testing, and documentation. It emphasizes that personnel must be qualified and hygienic, and equipment must be cleaned, to prevent contamination.