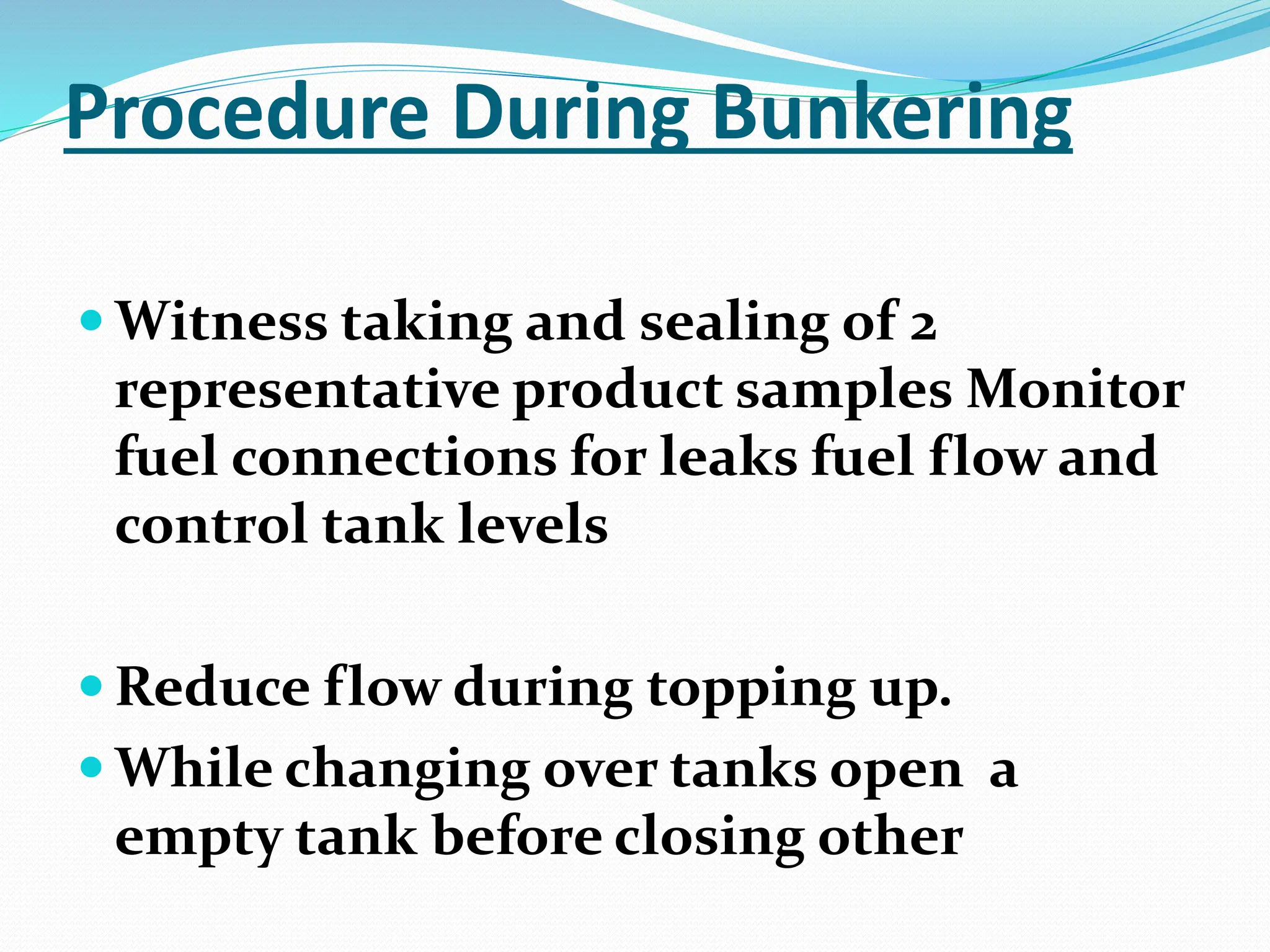

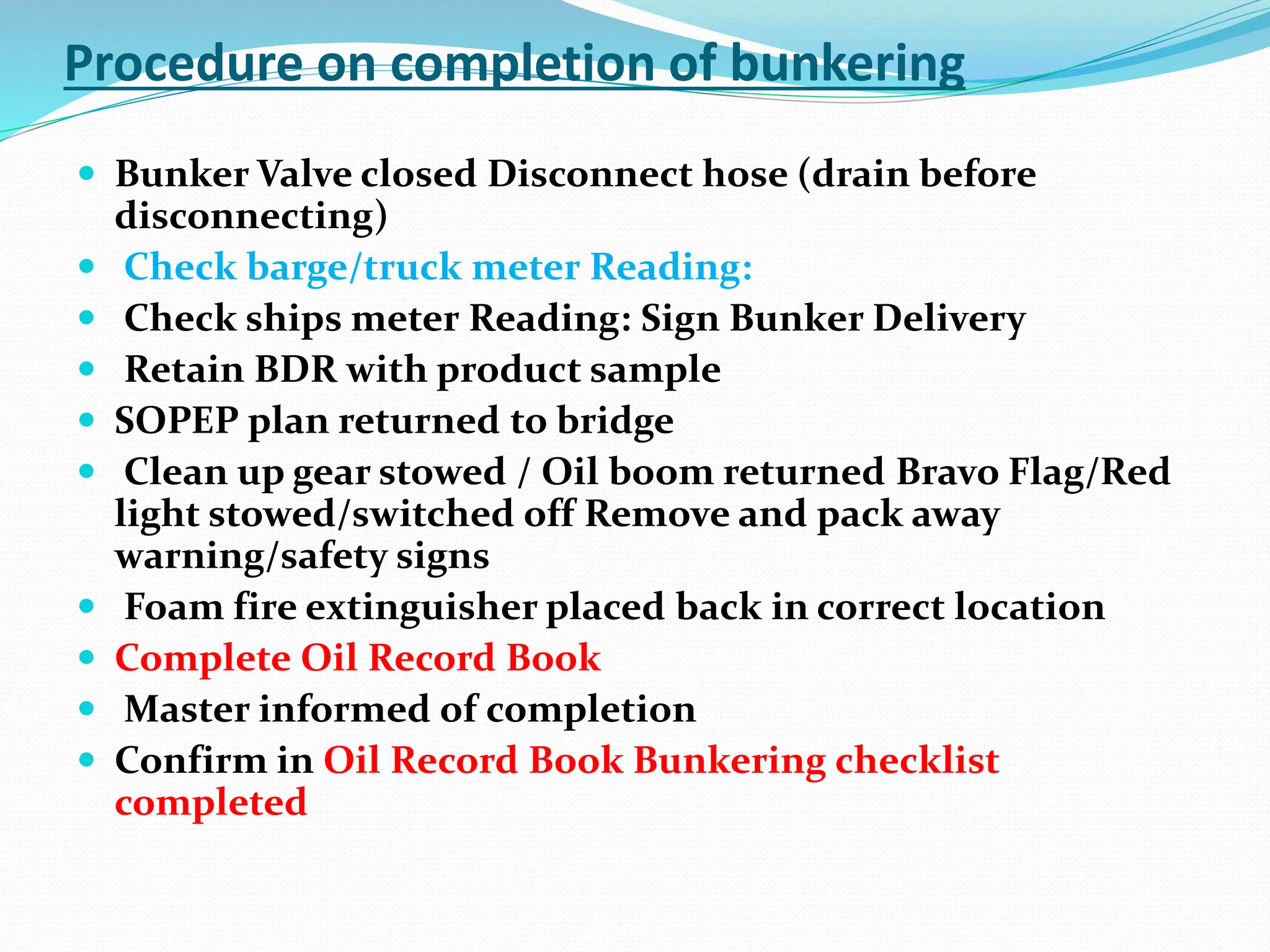

The document outlines the detailed procedures and safety measures for bunkering operations, emphasizing the roles and responsibilities of the chief engineer. It includes pre-bunkering checks, fuel transfer processes, safety protocols, and post-bunkering actions. Compliance with safety measures, verification of fuel quality, and proper documentation are highlighted as essential components of the operation.