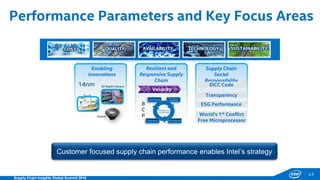

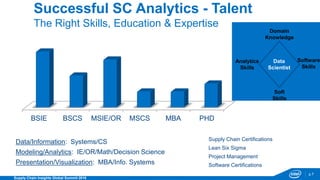

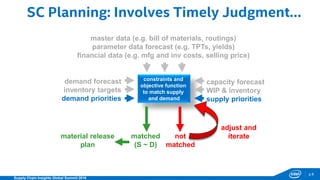

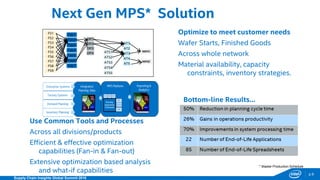

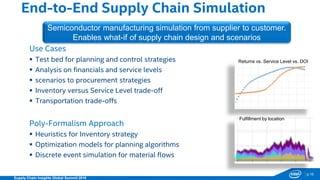

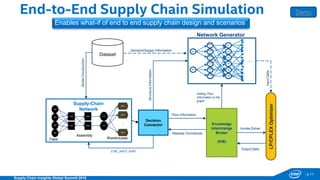

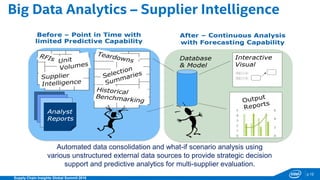

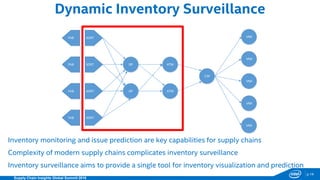

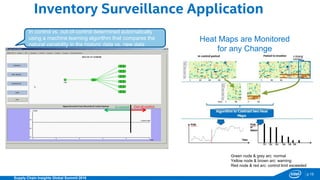

The document details Intel's supply chain strategy, emphasizing the importance of analytics in enhancing efficiency, social responsibility, and customer focus. Key themes include innovation, complex supplier networks, and the role of big data in optimizing supply chain operations. It also highlights tools for forecasting, inventory management, and end-to-end supply chain simulations to improve overall performance.