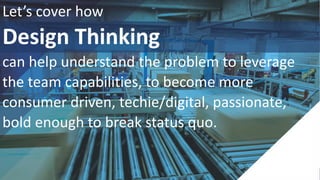

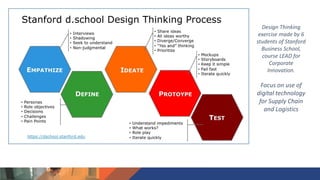

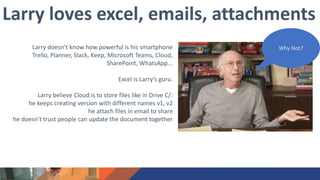

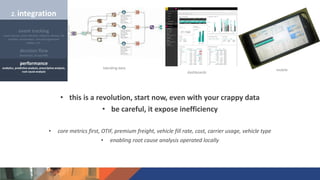

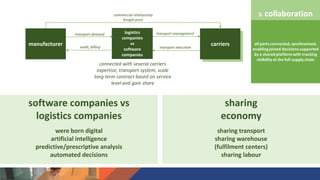

This document discusses digital transformation in logistics. Technologies like big data, analytics, AI, IoT, and robotics promise to transform business operations by raising quality, increasing flexibility, and boosting productivity. However, digital transformation is challenging for large, established companies not born in the digital age. The document proposes using design thinking to understand problems and leverage team capabilities to become more consumer-driven, digital, and willing to break from the status quo. It also recommends a simple framework for digital transformation in logistics focusing on foundations, integration, and collaboration. Finally, it discusses deploying global analytics for logistics by starting with pilot markets and key metrics before global rollout.

![The digital world is disrupting the industry and moving Logistics to

forefront of business strategy enhancing consumer experience [1] [2].

Apple, Amazon, Ocado, IKEA... have pushed the bar higher.

[1] https://www.gartner.com/doc/3847509/logistics-revolution-navigating-route-ahead

[2] https://www.mckinsey.com/business-functions/operations/our-insights/digital-transformation-raising-supply-chain-performance-to-new-levels](https://image.slidesharecdn.com/digital-transformation-in-logistics-200120011206/85/Digital-Transformation-in-Logistics-3-320.jpg)

![Big Data, Analytics,

AR/VR/MR, IoT,

Robotics, AI, Digital

Biology:

collectively, these

technologies promise to

transform business

operations, raising quality,

unleashing new levels of

flexibility and boosting

productivity [3].

[3] https://www.mckinsey.com/business-functions/operations/our-insights/operations-blog/ops-40-the-human-factor-recognizing-the-capability-challenge](https://image.slidesharecdn.com/digital-transformation-in-logistics-200120011206/85/Digital-Transformation-in-Logistics-4-320.jpg)