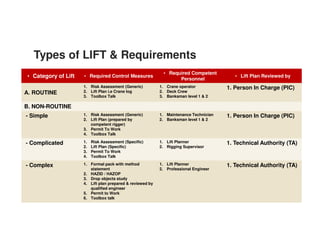

The document outlines best practices for lifting and hoisting in the oil and gas industry, emphasizing the importance of risk assessments, lift plans, and the selection of competent personnel for various types of lifts. It details the necessary safety measures and procedures for routine, non-routine, and complex lifting operations, including the correct use of wire rope slings and the application of enhancement factors for load limits. A strong emphasis is placed on maintaining a 'hands-free' culture to reduce hand and finger injuries during lifting operations.